Page 1 :

. h of materi Se es, , gato” io terial and products, simplification of processes and improvemen ts, ip om of transport and marketing.”) This widel ted ston fi , the, V sys od by Prof. Florence and refers t Y accepte definition follows the, es pak ers to the minimisation of waste as the core, i (pale 5 i . . ; ., ‘ Gol. oat gig is both an attitude and a process. As an attitude, or 8 the > fi more rational control of world economic life through the, at of scientific en is possible. As a process, it implies the application of, jgesnod® ofscience toa" problems arising in the organisation and conduct of production,, potion and consumption. In the first place, Col. Urwick underlines the importance, A applicae™ of scientific method to the control of the economic life of which industry, ital part. He refers to rationalisation as an attitude which accepts this basic tenet, ain with probems of economic organisation including industry. Secondly, he looks, ‘pit as the process of the application of scientific methods to all departments of industry, f ding production, distribution, etc., , yp will be noted that various definitions presented here emphasise different features, ationalisation. Nevertheless, the basis of rationalisation lies in a scientific attitude, ats the problem besefting industrial sector of the economy, or a particular industry., is assentially directed towards the removal of all possible causes of waste and inefficiency, jpdustry, and the establishment of condition which will be conducive to higher productivity., che essence of rationalisation”, to use Mr. Giri’s words, “is a revolutionary change, j methods which scraps obsolete traditions.”, , Measurers of Rationalisation : If rationalisation involves an attack on the causes, flow productivity, it will be necessary to ascertain, in the first place, the reasons for, yaste and inefficiency. The history of industry all over the world reveals the following, pajor causes of wastage, inefficiency and low productivity :, , 1. Scramble for Scarce Resources: Periods of shortage characterise almost all, ompetitive economies. In such times the resources of different kinds such as raw materials,, equipment or finances are all in short supply relative to the demand for them. This, eates some kind of a scramble for the scarce resources. Each producer is anxious to, secure the largest possible share of the resources without caring either for the other, producers or for the economy as a whole and makes an all-out attempt for this purpose., In such a situation, only a handful of firms may be able to get all their requirements, of available resources. Most of the individual firms may have to rest contented with, a very small share of the scarce resources. Obviously, they will not be able to make, proper use of their share, and whetever they are able to get may be wasted. In the, circumstances, rationalisation can be helpful only if it can tackle the problem of the, scramble for scarce resources effectively. It need hardly be pointed out that the chief, cause of such a scramble is lack of planning and control in their distribution among, the various firms which need them. The first measure of rationalisation would, therefore,, be to take steps to ensure a joint and planned utilisation of the available resources., , 2. Idle Plant Capacity : There is a general tendency among firms to increase, their plant capacity considerably during periods of prosperity. This is done in the fond, hope that the demand for the products of each unit of an industry will continue to be, what it is during the unusally prosperous periods of booms. This hope is, however, seldom, justified by the events that follow., , The oncoming of a period of depression has an extremely adverse effect on demand., Although there is a fall in the demand, the firms continue to produce at the same pace

Page 2 :

Na aeatig: Lee OO ED PROTO Se ee, , same plant capacity. However, it does not take ee es 0 rea ise, producing far in excess of demand and are a t is worked urces, ig, ds to a cut in production, The plant gud eqtpmen aia idle Teac below, € maximum installed capacity : in fact, a part of it has to rem eee ae Plant, obviously a source of wastage becuase it involves oe ci sts In the fo of, Interest and depreciation w ich have to be borne whether the plant 18 worked or ot., industry suffering from over-capacity cannot hope to achieve See Costs, , maximum Productivity unless the idle plant capacity is cut away. oe 'SAHON ts, ther efore, concerned with the removal or serapping of idle plant capacity. This may be Tegardeq, aS an important measure of rationalisation, As the Belfour Committee suggested in j, , report, “an operation of cutting out dead wood may be essential for the speedy Testoration, of prosperity.” The Scrapping of idle capacity’ can be achieved only when all the, in an industry suffering from this malady také some combined action after a, consideration of the general demand for the products and the natalie? ie, individual units. Historically, during the depression of the ‘thirties, , rationalisation were directed mainly towards the removal of the idle plan, industry., , and with the, that they are, realisation lea, , is, , & Care, Pacity of the, Measures of, , t Capacity in, , 3. Unnecessary Varieties : One of the causes of wastage in industry, be traced to competition among firms is the existence of a large number of unnecegg,, varieties of some products in the market. Varieties multiply partly on account of the, illogic of the consumers and partly due to actions of producers. The consumers are very, Soon tired of using the same old thing and desire a new brand name, a new shape, and design, or a different colour for the same type of product every now and then. Attractive, advertisements are meant to exploit this eagerness of the consumers for a new brand, or variety of the product already being used. There is, so to Say, an irrational craze, for novelty among the consumers. A new firm entering the market can hope to establish, itself on firm ground only when its product is different from the others already in the, market at least in respect of its appearance. Likewise, firms already established in the, field have also to introduce new varieties of their products from time to time in a bid, to win over customers from the rival firms. By and by, the varieties become so large, in number that every producer produces a particular variety on a small scale to cater, , that can, , and minimising the cost of production, is intended to reduce both the cost 9, erience of the U.S.A. in this respect i, , As a measure of rationalisation, standardisation, production and the cost of distribution. The exp, both interesting and instructive. The first atte, , of Commerce established the Division

Page 3 :

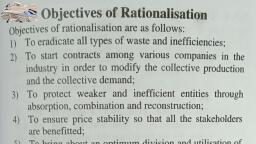

(gas Division) to take up the work of reducing the number of varieties of various, p cts iD collaboration with the organisations of manufacturers. The Division did, Cy pndable work in this regard effecting considerable reduction in the number of varieties., f'960, for instance, the varieties of convectors were reduced from 1,000,000 to just, | 5 (percentage of reduction = 99.9). Similarly, in the cases of hospital and institutional, 0 im textiles, varieties were reduced by 96% (from 459 to 26, in 1949)., 4, Obsolete Machinery : Production with obsolete machinery in plants of less than, optimum size is, for obvious reasons, uneconomical. Efficiency can be increased only, [a adequate steps are taken for the modernisation of plant and the replacement of, rete machinery by new up-to-date machinery. To take the case of the present-day, iosttY> man-operated machinery is fast becoming antiquated and obsolet on account, t ihe invention of labour-saving gadgets and.automatic machinery. If, therefore, the firms, | jn industry discard the old machinery and equip their plants with automatic machinery,, t jductivity can be increased many times. Similarly, if the plants are properly managed, people who are well-versed in the latest techniques of management, productivity, F pound to rise. The replacement of obsolete machinery by up-to-date machinery and, je increase in the efficiency of management at the plant level on an industrywide scale, y, therefore, be regarded as important measures of rationalisation. Sometime (as in, indi presently), this aspect is given so much of importance that automation is considered, ibe the whole function of rationalisation. This will, however, be going too far. Automation, 4 modernisation of plant have far-reaching implications which are, quite often, wilfully, Jost sight of. There is hardly any doubt about the fact the these measures will leave, some people unemployed, at least immediately. If these steps are taken very fast, there, ig a danger of large-scale unemployment of workers. That will run counter to the very, pasis of rationalisation because it will mean the wastage of human resources and lack, jf rational thinking on the part of management and the employers. The programme, of automation, etc., should therefore, be introduced gradually so that unemployment does, not assume serious dimensions., Features of Rationalisation, , The basic features of rationalisation may be stated as under :, , 1. Combination : Rationalisation calls for the amalgamation or merger of small, or weak units with big and efficient units. Moreover, it requires joint and united action, on various matters which are intimately connected with efficiency such as the removal, of over-capacity, the planned utilisation of scarce resources, etc. This will necessitate, setting up some sort of a joimt authority in which the powers of control are vested., , 2. Standardisation : Standardisation of products is another important feature of, rationalisation. It calls for the elimination of unnecessary varieties and the restriction, of production to a few varieties. In this manner, each variety can be produced at the, optimum level, i.e., at the point of the lowest average cost of production. It will also, put an end to the wasteful expenditure on competitive advertisement and cross-freights., , 3. Specialisation : Specialisation is a feature of rationalisation that follows from, standardisation of production. When production is concentrated over a limited number, of varieties and is carried on by a small number of efficient and powerful units, each, firm tends to specialise in a particular variety. Such specialisation brings a number of, , economies including conservation of resources and avoidance of cut-throat competition, in its wake.

Page 4 :

wet £uUv0lications Business Vreéamusaton, , 4. Simplificat:, simplification montio® + Both standardisation and specialisation of pro duction, Production and pro Uction. This, is turn, means a rise in productivity through lead ;, 5. Whiten e costs. It further leads to increased sales for each Vanna, Seeks to rieslen ee oe and modernisation and automation of plant : Ration, ., to replace sidat Ga _ functions which were being performed by human late Isatio,, In other word at has Srown out-of-date with better types of machinery and eq,” and, ord’s, automation is one of the distinctive features of rationalisatiy, nt, , 6. Scienti :, Scientific management on industry-wide scale : Rationalisation ealls, w 8 for a, , The wactanee. — ee of management in the various firms constituting an indy, on scientific inv. e e or unsystematic management must give place to management e 7, will Waranatt & gation. The systematic attempt at raising the efficiency of mana, Seq, aturally lead to higher productivity which is the goal of rationalisation Cement, cach inne research : Rationalisation banks heavily on programmes of industy, ieee Ee ee . ee the most economical processes of production. Industrial researe,, Sci drinel Ty of such processes possible and enables the quality of Bo0ds to be, 8. Social objectives : Rationalisation is concerned not merely with a rise in Productiy;, it 1S concerned equally with the prosperity of all sections of society. The banat, rationalisation should be shared by producers, workers and.consumers alike. The prod Soh, should be enabled to reduce costs and increase profits. The workers should receive es, share of prosperity resulting from rationalisation in the form of increased earnings, etn: fe, work-loads and more amenities of social life. The consumers must get better aie, of products at relatively cheaper prices. Schemes of rationalisation should not be pe, through at a speed that will cause large-scale unemployment of workers in industry,, DIFFERENCE BETWEEN RATIONALISATION AND, SCIENTIFIC MANAGEMENT, , Both scientific management and rationalisation seek to introduce scientific methods, of organisation and work in industry in place of the outdated and unsystematic methods,, The immediate object of both these movements is to increase efficiency and productivity, and bring about the maximum utilisation of resources of all kinds. Because of these, common grounds covered by both, many authors are inclined to think that rationalisation, and scientific management are fundamentally the same. Peter Drucker, for instance, is, of opinion that Germany merely coined the term rationalisation for all that had been, practised in the U.S.A. as scientific management. But in spite of the striking resemblance, between the two, some basic points of distinction may be noted here :, , 1. Scope : Rationalisation has a much wider scope than scientific management., Scientific management can be introduced by any particular firm with a view to increase, its efficiency. Rationalisation, to the other hand, concerns itself with the problems of, industry and not of particular individual units constituting an industry. ‘Thus, scientific, management tries to remove the causes of wastage and inefficiency within a aa, while rationalisation seeks to eliminate waste throughout the industry. ao i, cannot, thus, be introduced in one particular firm leaving other firms hnaffecte 2 si, , 2. Measures : The measures which are taken under rationalisation are quite at, from those adopted under scientific management. Let us take each one of the ma), , easures of rationalisation. _ — a, ™ () Industrial combinations: Rationalisation seeks to end unhealthy a os e, concerns and tries to settle the problem through amalgamation and mergers. 1né

Page 5 :

a ‘ 7 ey he meee eect cory i ant, , ‘ont units of an industry are encouraged to join and merge with a 7, , ipo ts in the interests of efficiency of a particular industry as a whole. a “, , dot mig in nO Way concerned with industrial combination. Its only concer™ "*, id tries to achieve, , pent . . . :, , unit whose efficiency is sought to be raised. It, therefore, ., sil developing a spirit of co-operation between the employers and the employees, Fyjooe articular unit. _ ails, pi? at oidance of scramble for resources : Rationalisation aims at avoiding u n, * i for resources among various firms in an industry during periods of eT y, ple g joint and planned allocation by authority set up by all the units or by the, i ent. In this way, each unit gets a reasonable share of the total available ae, ie can be avoided. Obviously, any one concern under scientific management canno, cb? this task. It will have to work with whatever it can get out of the pool of availa Bie, (0 At best, it can make proper use of its own share of resources. But it 1s, oy ‘not a measure of scientific management to arrange for the proper distribution, j 2 urees among various concerns in any industry. :, Gi) Removal of idle capacity : If an industry is rationalised, the joint authority, , : for the purpose will take steps to remove any idle capacity by closing down the, UP plants. Scientific management does not seek to tackle this problem of adjusting, , cient ; tee :, lant capacity to demand because it is confined to the functioning of a particular, , se P, , Ps Standardisation of varieties : One of the important measures of rationalisation, . the standardisation of varieties and the elimination of unnecessary varieties which, i ake for higher cost of production. Thus, the production of each variety retained will, ip and the cost of production will be brought down. Scientific management concerns, ielf with the efficient production of whatever varieties are already being produced without, jiminating the unnecessary ones. It will be appreciated that a single firm even under, ientific management cannot afford to cut down some varieties it has been producing, or the simple reason that the rival concerns will then introduce some new varieties, nd capture the market., , 3, Coverage : Scientific management is concerned primarily with the efficient, nanagement of production. To this end, it organises labour and productive processes, m scientific and systematic lines. It is not concerned with the problems of marketing,, fnance and transport, etc. Rationalisation, on the other hand, has a wider coverage and, abroader approach. It concerns itself with the regulation of production, marketing, finance,, advertising and transport on industrywide scale., , 4, Mechanism : Rationalisation does not have a fixed and pre-determined mechanism., The various measures outlined above need not always be taken in their totality, nor, is it absolutely necessary to follow any particular order in putting them into effect, On, the other hand, scientific management has come to have a more or less well-defined, _ well set mechanism which has been recommended and accepted by practically all, , S exponents., , 5. Social objectives : Thanks to the deliberations of economists, rationalisation, has become definitely associated with certain social objectives such as raising the, remuneration of workers, reducing the prices of the products for the benefit of consumers, improving the quality of the products and raising the standards of living of the membe: ;, of the society. On the other hand, scientific management aims only at more okie, Management of the existing firms through the use of scientific methods of research and