Page 1 :

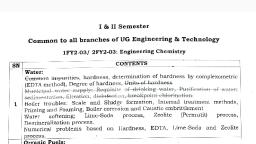

8.7 Preventive Measures, 8.7.1 Proper Design, , , , 8.1 Introduction, 8.2 Types of Corrosion, , 8.3 Dry or Chemical Corrosion 8.7.2 Using Pure Metal, , 8.4 Wet or Electrochemical Corrosion (Theory) 8.7.3 Using Metal Alloys, , 8.4.1 Comparison of Chemical with Electrochemical 8.7.4 Sacrificial Protection, Corrosion, , 8.7.5 Electrical Protection, , 8.5 Types of Electrochemical Corrosion 8.7.6 Protective Coating or Barrier Protection, , 8.6 Factors Influencing Corrosion, , , , , , INTRODUCTION, , , , As soon as the metals are extracted from their ores, the reverse process also starts i.e., nature tries to, convert them back into the form in which they occur. This is due to the chemical attack of the gases, present in the atmosphere on the surface of the metal converting it into compounds such as oxides,, sulphides, carbonates, sulphates etc. It can also take place due to electrochemical interaction of metal, with the environment., , The process of slow destruction of metal due to chemical or electrochemical attack of the, environment at their surfaces resulting into the formation of compounds such as oxides, carbonates,, sulphides, sulphates etc., is called corrosion., , The most common example of corrosion is the rusting of iron. Rust is hydrated ferric oxide,, Fe,0, xH,0. Some other examples include tarnishing of silver, development of green coating of basic, carbonate [CuCO, + Cu(OH),] on copper and bronze etc., , Corrosion occurs at the surface of metal and is a slow process, but its ill effects are numerous. It, destroys metallic equipments, machines and instruments and reduces their efficiency. It is, therefore,, important to study its mechanism and measures to control it to minimize the loss due to corrosion., , In this chapter we would learn types of corrosion, their mechanism of occurrence, factors effecting, corrosion and measures which are usually adopted for their prevention., , 305, , Scanned with CamScanner

Page 2 :

PAA Ee. fe See ee ee, Ea TYPES OF CORROSION, , , , low in the form of a table. The shaded areas Tepresent, , Various types of corrosion processes are given bel e, he types related to each main type., , the main types, which have been sub-divides into t, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , Corrosion, i, f t t, Other, Diy or Wet or tmospheric | | Soil, (Chemical) (Electro-chemical) [a mospHe: forms, , , , , , , , , , , , , , By Other Liquid Intergranular Erosion Microbiological, , oxygen gases metal, , , , , , 1, , Galvanic Pitting Crevice Concentration Waterline Stress, cell or, differential, aeration, , The details of only some important types will be discussed here., , [EB DRY OR CHEMICAL CORROSION, , sulphur dioxide and, , The direct chemical action of atmospheric gases such as oxygen, halogens,, halides,, , hydrogen sulphide with metals resulting into the formation of compounds such as oxides,, sulphates and sulphides is referred to as chemical corrosion., , It is mainly of the following three types., (a) Corrosion by oxygen (oxidation corrosion): Atmospheric oxygen reacts with metals in the, absence of moisture forming their respective oxides., Alkali metals (Li, Na, K, etc.) and alkaline earth metals (Be, Ca, Sr, etc.) are oxidized at low, temperatures, whereas all other metals (except, Ag, Au and Pt) are oxidized at high temperatures., , Mechanism: The process of oxidation starts at the exposed surface of metal. The metal loses, electrons and changes to metal ions, whereas oxygen accepts the electrons and changes to oxide ion., , 2M — > 2M” (Metals ions) + 2ne"(loss of electrons, oxidation), n a :, 2 O, + 2ne7—> nO? (Oxide ions) (Gain of electrons, reduction), overal! reaction, A, 2M + a 0,—> M™ + 2n0* —>+ MO,, , Metal ion Oxide ion (Metal oxide), , This oxide layer formed acts as a barrier towards further oxidation. The continuation of the, oxidation process depends upon two factors: (i) the nature of the oxide film formed, (ii) the rate of, diffusion of the metal ion and the oxide ion through the layer formed., , Scanned with CamScanner

Page 3 :

Corrosion AND Ms Controt ff, , (i) Nature of oxide film formed on the surface, , (a) When the oxide film is stable, tightly adhering and impervious in nature, it acts as a, protective coating and further action of atmospheric oxygen on the metal is prevented., For example, oxide films formed on Al, Cu, Sn and Pb are of this type., , (b) When the film formed is unstable and decomposes back to metal and oxygen, oxidation, corrosion can not continue further. Metals like Ag, Au and Pt form this type of oxide, films., , (c) When the volatile film is formed, it gets volatilized immediately making the metal surface, , available for continuous attack. For example, Mo forms volatile oxide and it is corroded, completely with passage of time., , 2Mo + 30, —> 2MoO, (Volatile), , (d) When the oxide film is porous in nature, the metal is attacked by oxygen through the pores, , and cracks and the corrosion continues till the entire metal is converted into its oxide., Piling-Bedworth Rule: This rule is helpful in deciding whether the oxide film formed on the, metal surface is porous or non-porous. According to this rule:, , “An oxide film is non-porous i.e., protective, if the volume of oxide is at least equal to or, greater than the volume of metal from which it is formed. However, if the volume of the oxide is, less than the volume of the metal, the oxide film is porous i.e., non-protective.”, , Metals like Al form oxide having greater volume as compared to the metal, so they form, non-porous oxide layer and further oxidation of the metal is prevented. On the other hand, alkali and, alkaline earth metals form oxides having lesser volume as compared to the metal, they form porous, oxide films which allow further attack of atmospheric oxygen through the pores and the metals are, , completely corroded., , (ii) Rate of diffusion of metal ions: The metal oxide film formed at the surface acts as an, interface. For the oxidation to continue further, the metal ions (M"*) must diffuse outwards, and the oxide ion (O7-) inward through the interface for further action between them. This, happens through the pores of the porous film only and not through the non-porous film. The, , metal ions being smaller in size as compared to the oxide ions diffuses outward at a faster, rate than the oxide ions diffusing inward., , (5) Corrosion by other gases: Besides oxygen, gases like Cl,, SO,, H,S, CO, and F, also react, with metals. The corrosive effect of these gases depend upon their chemical affinity for the, metal and also upon the nature of the compound formed by them i.e., whether the film formed, is protective or non-protective. For example, Cl, reacts with silver forming a protective (non, porous) film of AgCl which prevents further attack of Cl, on Ag. But Cl, forms a volatile, , chloride of tin. Similarly, HS gas at high temperature reacts with iron forming a porous FeS, film and corrodes iron., , (c) Liquid metal corrosion: When liquid metal flows over solid metal at high temperature,, corrosion takes place which is called liquid corrosion. It weakens the solid metal due to, (i) penetration of the liquid metal, (ii) dissolution of the solid metal in liquid metal., , A common example of this type of corrosion is the corrosion of cadmium rods taking place, due to sodium metal acting as coolant in nuclear reactors., , Scanned with CamScanner

Page 4 :

Ea TA Texmoox oF Enaincenina Creaustry, Egg wer OR ELECTROCHEMICAL CORROSION (THEORY), , It occurs mostly under wel or moist Conditions, , Wet corrosion is more common than dry corrosion., ry referred to as electrochemical COomosion, , through the formation of electrochemical cells and is therefore,, The mechanismy/theory of electrochemical corrosion involves:, , (i) The existence of separate anodic and cathodic areas be, , the conducting solution, —e, , (ii) Oxidation (loss of electrons) take place at the anodic area and t om te ls destroyed by, , either dissolution or combination with oxygen. Hence corrosion always takes place a the, , anode,, , smveen which current flows througy, , M— M* + ne> (oxidation), M™ forms compounds such as oxides or dissolves in solution., , (iii) Reduction (gain of electrons) takes place at the cathode. The electrons Jiom the anode are, accepted by the dissolved oxygen forming ion such as OH- or OF ions., , i, 2, or O, + 2e-—> 20* (Reduction), , (iv) The metallic ions formed at the anode and non-metallic ions formed at the cathode diffuse, through the conducting medium and combine to form the corrosion product some where, between anodic and cathodic area., , Wet corrosion involves flow of electron current, between the anodic and cathodic areas. The, anodic reaction involves dissolution of metal as corresponding metallic ions with the liberation of free, electrons. Whereas, the cathodic reactions accept electrons by two ways: (i) evolution of hydrogen or, (ii) by absorption of oxygen. The evolution of hydrogen and absorption of oxygen in cathodic reaction, depends on the nature of corrosive environment., , (# Evolution of Hydrogen: The process of corrosion in which H, is liberated is called evolution, , of hydrogen type corrosion. This type of corrosion usually takes place in acidic environment., Thus, acidic medium (absence of oxygen) hydrogen ions acquire electrons with the liberation, of H, gas cathodic reaction, whereas in the anodic reaction metal atoms lose their electrons, to the environment and pass into solution in the form of +ve ions., , 2H,O* + 2e°-— 2H,0 + Ht, , or simply 2H* + 2e-—> H, T (Cathodic reaction), , In neutral and alkaline medium (in the absence of oxygen) the reaction taking place will be, 2H,0 + 2e°—> 20H” + H, T (cathodic reaction), whereas Fe—> Fe” + 2e" (anodic reaction), , e.g., if iron metal is used, the dissolution of iron as Fe* ions with the evolution of electrons in anodic, reaction., , O, + H,0 + 2e-—> 2OH- (Reduction), , Fe —> Fe™* + 2e" (oxidation), , These electrons flow through the metal, from anode to cathode, where H* ions of acidic solution, are eliminated as H,., , 2H" + 2e°—> H, T (Reduction), Overall reaction: Fe + 2H*——> Fe** +H,, , Scanned with CamScanner

Page 5 :

Corrosion AND Its Contnon Hl Eu, , _ Therefore, this type of corrosion cause displacement of hydrogen ion from the acidic solution by, metal ions., The above statements can be easily understood from Fig. 8.1., athe von se : hagrams, it is Clear that anodic areas are very large in comparison to cathodic, reas 1¢ metals, above hydrogen in the electrochemical series have a tendency to get dissolved in, acidic solution with simultaneous liberation of hydrogen, , , , Acidic solution, (electrolyte), , , , , , , , , , , , , , , , , , ‘odic Anodic, , SG SS, Anodic Cath S Tron metal, area, arca \ area S, , LL, , , , , , , , , , , , , , , , , , , , Fig. 8.1 Mechanism of wet corrosion by hydrogen evolution, , (i Absorption of Oxygen: This type of corrosion occurs in neutral environment (such as NaCl, solution used as electrolyte), The popular examples of absorption of oxygen type corrosion is rusting of, iron in neutral aqueous solution of NaCl in the presence of atmospheric oxygen., , The surface of iron is usually covered with a film of iron oxide. If there are some cracks in iron, oxide filnf, an anodic area is developed on the surface, whereas the wet metal part act as cathodic area., In this corrosion reaction cathodic area is much more large in comparison to anodic area., , The above overall reaction mechanism is represented diagrammatically in Fig. 8.2., , , , , , , , , , , , , , , , , , , , , , i— Aqueous neutral, solution, Tm PAA NLU Iron oxide, Cathodic Anodic Cathodic film, area area area, Tron metal, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , Fig. 8.2 Mechanism of wet corrosion by absorption of oxygen type corrosion, , . Thus, from the above diagram it is clear that at the cathodic area, iron metal dissolves with the, liberation of electrons as, Fe Oxidation Fe2* +2e7, The above evolved electrons flow from anodic areas through iron metal where electrons are, , taken up by the dissolved oxygen as, , Scanned with CamScanner