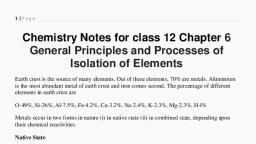

Page 1 :

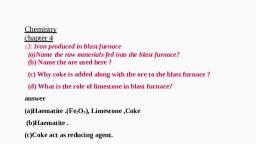

A few important processes used in metallurgy Smelting:, Smelting is a pyro-chemical process, in which the ore is mixed with flux and fuel and strongly heated., The heat is so strong that the ore is reduced to even metal as in case of iron (Fe), and the metal is obtained in molten state. During smelting the impurities (gangue) in the ore react with flux to form slag which is removed., For haematite (Fe₂O₃)ore, coke is used as fuel and lime stone (CaCO₃) is used as flux. The smelting is carried out in a specially built furnace known as blast furnace. , The reactions inside the furnace are: , 2C + O₂ –––– > 2CO, Fe₂O₃ + 3CO –––– > 2Fe + 3CO₂, CaCO₃ –––– > CaO + CO₂, CaO + SiO₂ –––– > CaSiO₃

Page 3 :

Roasting: Roasting is a pyro-chemical process in which the ore is heated in the presence of oxygen or air below its melting point. The products obtained in the process also are in solid state. Generally reverberatory furnace is used for roasting. , 2ZnS + 3O₂ –––– > 2ZnO + 2SO₂, Calcination: Calcination is a pyro-chemical process in which the ore is heated in the absence of air. The ore gets generally decomposed in the process. , MgCO₃ MgO + CO₂, CaCO₃ CaO + CO₂ , Flux: Flux is a substance added to the ore to remove the gangue from it by reacting with the gangue. If the impurity (gangue) is acidic substance like SiO₂, basic substance like CaO is used as flux and if the impurity is of basic nature like FeO acidic flux like SiO₂ is added to the gangue. , CaO + SiO₂ –––– > CaSiO₃, FeO + SiO₂ –––– > FeSiO₃

Page 4 :

Furnace:, Furnace is the one which is used to carry out pyro-chemical processes in metallurgy. We have mainly three parts in a furnace known as Hearth, Chimney and fire box., Hearth is the place inside the furnace where the ore is kept for heating purpose. Chimney is the outlet through which flue (waste) gases go out of the furnace. Fire box is the part of the furnace where the fuel is kept for burning., In Blast furnace both fire box and hearth are combined in big chamber which accommodates both ore and fuel., Reverberatory furnace has both fire box and hearth separated, but the vapours (flame) obtained due to the burning of the fuel touch the ore in the hearth and heat it. In furnaces like retort furnaces there is no direct contact between the hearth or fire box and even the flames do not touch the ore.

Page 5 :

Write short notes on i) Roasting ii) Calcination iii) Smelting. , Draw a neat diagram of Reverboratory furnace and label it neatly?