Page 1 :

Extraction of metals from the ores: , The extraction of a metal from its ore involves mainly three stages. They are: , I) Concentration or Dressing , II) Extraction of crude metal , III) Refining or purification of the metal., Concentration or Dressing of the ore , Ores that are mined from the earth are usually contaminated with large amount of impurities such as soil and sand etc. Concentration or Dressing means, simply getting rid of as much of the unwanted rocky material as possible from the ore. The impurities like sand and clay are called gangue., Enrichment (concentration) of the ore: Various physical methods are used to enrich the ore. In many cases, it is possible to separate the metal compound from unwanted rocky material by physical means An example for this is froth flotation.

Page 2 :

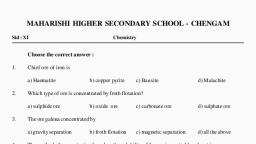

The physical methods adopted in dressing of the ore (or) enriching of the ore depends upon difference between physical properties of ore and gangue., Hand picking , If the ore particles and the impurities are different in one of the properties like colour, size etc., Using that property the ore particles are handpicked separating them from other impurities., Washing , Ore particles are crushed and kept on a sloppy surface. They are washed with controlled flow of water. Less densive impurities are carried away by water flow, leaving the more densive ore particles behind., Magnetic separation , If the ore or impurity, one of them is, magnetic substance and the other non-magnetic, substance they are separated using electromagnets.

Page 3 :

Froth flotation , This method is mainly useful for sulphide ores which have no wetting property whereas the impurities get wetted., The ore with impurities is finely powdered and kept in water taken in a flotation cell., Air under pressure is blown to produce froth in water. Froth so produced, takes the ore particles to the surface whereas impurities settle at the bottom. Froth is separated and washed to get ore particles.