Page 1 :

24, BASIC MECHANICAL ENGINEERING, 9. The purpose of reaming is, (a) for making a hole initially, (c) to improve the finish of the hole, (b) to enlarge the diameter of hole, (d) to achieve correct diameter., 10. Which is the most important parameter by which a lathe machine is specified, (a) distance between centres, (b) maximum speed of spindle, 6., Boilers, (c) length of bed, (d) maximum diameter of the job it can swing., Syllabus : Names and functions of principal parts, classification,, Boiler mountings and accessories, Draught-natural and artificial,, Height of chimney, Equivalent evaparation and boiler performance., ANSWERS, 1. (b), (9), (v), (p), 9. (c), (b) 's, (p) 0, 7. (c), (p) 9, (9) 7, 6.1 Introduction, Generally Boilers are used to produce steam at high pressure. The steam, generator is also known as boiler. Steam is the most important working substance, used for power generation in steam engines and in steam turbines The generation, of steam is done by evaporating the water in boilers at appropriate temperatures, and pressures., A "Beiler" may be defined as a combination ofequipments to generate steam, from water by burning fuel. In industries the steam may be used for different, purposes :, 1, Mechanical energy is generated in steam turbines., 2. Electrical energy is geherated in power plants., 3. For different heating processes industries as heating of groundnuts in oil, mills., 4. For bleaching purposes in textile industries., 6.1.1. Features of a Boiler, A good beiler sheuld have the follewing features :, 4. A boiler should produce maximum amount of steam at minimum cest., 2 The werking of beiler sheuld be safe accerding te Indian Beiler, Regulations (IBR) act., 3. A boiler should occupy small space., 4. Inspection and repairing of different parts should be easy., 5. It should have easy and quick starting., 6. In order to make the best use of the heat supplied, the boiler should have, proper arrangement of circulation of water and hot gases., 7. The boiler should be easily constructed., 8. Installation of the boiler should be easy., 9. Boiler's maintenance should be cheap and easy., 125

Page 2 :

126, BASIC MECHANICAL ENGINEERING, BOILERS, 127, 5.2 Classification of Boilers, 1. According to pressure of steam created in the boiler, (a) Low pressure boilers-which can generate steam pressure less than 100, par. Some boilers of this category are, there may be a bank of tubes. The heat is conducted through the walls of the tube, from the hot gases to the surrounding water., In water tube steam boilers, the water is contained inside the tubes which are, surrounded by flames and hot gases from outside., 1- Cochran boiler Veilixal, 2.-Lancashire boiler, 2.-Locomotive boiler., -Babcock Wilcox boiler., (b) High pressure boilers-which generate-pressure above 100 bar. These are, nore efficient and reduced quantity of steam required for same power generation,, ompared to low pressure boilers. Some boilers of this type are, 3. According to the position of furnace. The steam boilers, according to, the position of the furnace are classified as : (a) Internally. (b) Externally fired, boilers, (a) In Internally fired boilers, the furnace is located inside the boiler shell., Most of the fire tube steam boilers are internally fired., (b) In Externally fired boilers, the furnace is arranged underneath in a, brick-work setting, Water tube steam boilers are always externally fired., 4. According to the axis of the shell. The steam boilers, according to the, axis of the shell, may be classified as :, (a) Vertical boilers, and (b) Horizontal boilers, In vertical steam boilers, the axis of the shell is vertical. Simple vertical boilers, and Cochran boilers are vertical boilers., In horizontal steam boilers, the axis of the shell is horizontal. Lancashire boiler,, Locomotive boiler and Babcock and Wilcox boiler are horizontal boilers., 5. According to the number of tubes. The steam boilers, according to the, number of tubes, may be classified as :, (a) Single tube boilers and, (b) Multitubular boilers., In single tube steam boilers, there is only one fire tube or water tube. Simple, vertical boiler and cornish boilers are single tube boilers., In multitubular boiler, there are two or more fire tubes or water tubes., Lancashire boiler, Locomotive boiler, Cochran boiler, Babcock and Wilcox boilers, are some examples., 6. According to the method of circuiation of water and steam. The, steams boilers, according to the method of circulation of water and steam, may be, classified as :, 1-La Mont Boiler, 2 - Benson Boiler, 3. - Loeffler Boiler, 4, Velox Boiler., 2. According to the relative position of water and hot gases, (a) Fire tube Boilers or smoke tube boilers T, (b) Water tube Boilers, In fire tube boilers, hot gases pass through tubes which are surrounded with, vater. There may be a single or double tubes as in the case of Lancashire boiler or, Tube, Hot, sasD6, Water, (a) Fire tube hoiler., (a) Natural circulation boilers, and, (b) Forced circulation boilers., In natural circulation steam boilers, the circulation of water is by natural, convection currents, which are set up during the heating of water., In forced circulation steam boilers, there is a forced circulation of water by a, centrifugal pump driven by some external power., 7. According to the use. The steam boilers, according to their use, may be, classified as, Hot gases, Water, (a) Stationary boilers, The stationary steam boilers are used in power plants, and in industrial process, work. These are called stationary because they do not move from one place to, Hot gasès:, (b) Mobile boilers, (b) Water tube boiler., Fig. 6.1., another.

Page 3 :

Low water safety, valve, Superheated steam out, Steam stop valve, Water out, Safety valve, Water in, IManhole, Economiser, Fusible plug, Fire hole-, Fürnace tube(), Side flue, Bottom fjue, Blow-off cock, Fire - bridge arch, Bottom flue, Dampers, Side f, H Side flue, A Water, Steam, - Hot gases, Exhaust to Chimney, Fig. 6.2. Lancashire boiler., 128, BASIC MECHANICAL ENGINEERING, BOILERS, 129, The mobile steam boilers are those which move from one place to another., These boilers are locomotive and marine boilers., 8. According to the source of heat. The steam boilers may also be, classified according to the source of heat supplied for producing steam. These, sources may be the combustion of solid, liquid or gaseous fuel, hot waste gases as, by-products of other chemical processes, electrical energy or nuclear energy etc., Under the classification of boilers of relative position of water and hot gases,, fired tube boilers are further classified as, (a) Lancashire Boilers, (c) Locomotive Boilers, (b) Cochran Boiler, 6.3 Lancashire Boiler, It is a fire tube, stationary, horizontal straight tube, internally fired, natural, circulation boiler. It is used where working pressure, moderate. Normal working pressure in this boiler is about 15 bar and steam, generation capacity is upto 8 T/hr. These boilers have a cylindrical shell of 1.75 m, to 2.75 m diameter. Its length varies from 7.25 m to 9 m., power required are, Construction details and Working, Lancashire boiler consists of a long cylindrical external shell built of steel, plates, in sections riveted together. It has two large internal flue tubes. These are, réduced in diameter at the back end to provide access to the lower part of the boiler., A fire grate also called furnace, is provided at one end of the flue tubes on which, solid fuel is burnt. At the end of the fire grate, there is a brick arch to deflect the, flue gas upwards. The hot flue gases, after leaving the internal flue tubes pass down, to the bottom tube. These flue gases move to the front of the boiler where they, divide and flow into the side flue. The flue gases then enter the main flue, which, leads them to chimney., The damper is fitted at the end of side flues to control the draught and thus, regulate the rate of generation of steam. These dampers are operated by chain, passing over a pulley on the front of the boiler., A spring loaded safety valve and a stop valve is mounted on the boiler. The, stop valve supplies steam to the engine as required. A high steam and low water, safety valve is also provided., A perforated feed pipe controlled by a feed valve is used for feeding water, uniformly. When the boiler is strongly heated, the steam generated carries a large, quantity of water in the steam space, known as primary'. An antipriming pipe is, provided to separate out water as far as possible. The stop valve thus receives dry, steam., A blow-offcock removes mud etc., that settles down at the bottom of the boiler,, by forcing out some of the water. It is also used to empty water in the boiler, whenever required for inspection. Man holes are provided at the top and bottom of, the boiler for cleaning and repair purposes.

Page 4 :

Steam safety, valve, -Boiler shell, Stop valve, T Steam, Pressure gauge., Bracket, Pulley, Water leve, indicator, Super heater, Up header, A Water, Bafles, Steam, - Hot gases, Blow-off-cock, Mud box, HJoop ai, Damper, Exhaust gases, to chimney, Ash-pan-, Grate, Inspection, Inspection door, Fig. 6.3. Babcock and Wilcox Boiler,, 130, BASIC MECHANICAL ENGINEERING., BOILERS, 131, It is a water tube boiler. It consists maninly of three parts-, (i) A horizontal steam and water drum, (ii) A bundle of steel tubes., (iii) Combustion chamber., 6,3.1, Babcock and Wilcox Boiler, Construction details and working, note book, The boiler known as water and steam drum is made of high quality steel.. The 2, boiler drum is connected with the uptake header or riser and with the short tubes,, and is connected with the downtake header with the longer tube. The water tubes 3, are kept inclined at 15° to the horizontal. The inclined position helps the flow of 4, water. Combustion of fuel takes place in the fire grate, provided below the uptake, Chain, header., 5. The hot gases produce first rise upwards and then go down and then rise up, again and finally escape to the chimney through the smoke chamber. The front 4, portion of the water tubes comes in contact with the hot gases at higher temperature., So the water rises from the downtake header to the uptake header due to decrease, in the density, into the boiler shell, where water and steam are separated, steam, being lighter is collected in the upper part of the drum., Ladder, Down header, 3 Simultaneously, water enters the water tubes through the downtake header., Thus there is a continuous circulation of water from the water drum to the water, tubes and from the water tubes into the water drum. In order to superheat the steam,, the steam is made to pass through the superheater. The superheated steam coming, out through superheater is supplied through steam pipe and steam stop valve to the, turbine., 12 To blow off the mud and impurities present in the water through the blow off, valve ; mud box is fitted to the downheader., Merits and Demerits of Water Tube Boiler over Fire Tube Boilers, Merits :, 1. Generation of steam is much quickest due to small ratio of water content, to steam content., 2. Parts of water tube boilers are easily-accessible for cleaning, inspecting, and repairing., 3. Boilers can be easily transported and erected as its different parts can be, separated., 4. Its evaporative capacity is considerably larger., 5. Damage due to the twisting of water tube is less serious., Demerits :, 1. They require careful attention., 2. Failure in feed water supply led to the overheating of boiler.

Page 5 :

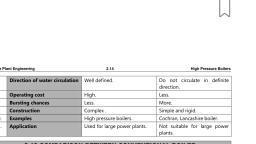

BOILERS, 133, BASIC MECHANICAL ENGINEERING, 132, 6.5. Comparision between Water Tube and Fire Tube Boilers, 3. It is less suitable for impure and sedimentary water., Water tube boilers, Fire tube boilers, 64. Locomotive Boiler, Locomotive boiler is a horizontal fire tube type mobile boiler. A modern, locomotive boiler is shown in Fig. 6.4. It is made of cylindrical shell '1' fitted with, fire box '2' at one end and smoke box '3' at the other end. Coal is burnt on grate, '4' in the fire box and flue gases pass through number of small fire tubes '5',, surrounded by water in the shell. The flue gases after passing through the tubes, enter into smoke-box from where they escape into atmosphere through chimney at, the top of the smoke box., The steam generated in the shell is collected over the water surface. A dome, shaped chamber known as steam dome, is fitted on the top of the shell. The steam, in the shell flows through a pipe mounted in the steam dome into the steam header,, which is divided into two parts. One part of the steam header is known as saturated, 1., Tube, Water, Hot gases, Hot gases:, Steam done 9, Whistle, Small chimney, Regulator 6, 2. The rate of steam generation is high, The rate of steam generation is less, Fusible plug, upto 45000 kg/hr., 3. Maximum temperature of steam can, be achieved upto 560°C., 4. Overall efficiency is upto 90%., 5. Operating cost is more., 6. It can produce steam upto a pressure, upto 9000 kg/hr., Maximum tempeature of steam can, be achieved upto 340°C., Overall efficiency is upto 75%., 2., Fire box, Operating cost is less., It can produce steam upto a pressure, Drum, Fire brick arch, of 225 bar, of 20-25 bar., Steam form boiler, 7. Construction is complex hence skilled, workers required., Construction is simpler hence less, skilled workers required., Ash-pit, dampers, 8. Size of boiler drum is small hence, Its transportation is difficult., transportation becomes easy., Fig. 6.3. Locomotive boiler., steam header and other part is known as superheated steam header. The superheated, steam coming out of superheater tubes is collected in the superheated header and, then fed to the steam engine., 6.6. High Pressure Boilers, A stop value '9' is provided on steam dome '10' and is called regulator. Also,, on the shell or dome, safety valve '11', stop valve, pressure and water level, indicator are mounted., Those boilers for which pressure is greater than 100 bar are classified as high, pressure boilers. Some special types of high pressure super-critical boilers are,, Lamont boilers, Benson boilers, Loeffler boiler and Velox boiler., 6.6.1. Advantages of High Pressure Boiler, 1. The efficiency and the capacity of the plant can be increased as reduced, quantity of steam is required for the same power generation, if high pressure steam, is used., 2. The tendency of scale formation is reduced due to high velocity of water., 3. The danger of overheating is reduced as all the parts are uniformly heated., 4The differential expansion is reduced due to uniform temperature and this, the possibility of gas and air leakages., 6.4.1. Important Features of Locomotive Boiler, 1. It is very compact., 2. The efficiency of locomotive boiler is about 70%., 3. Large rate of steam generation per square metre of heating surface., 4. The pressure of steam is limited to about 20 bar.