Page 1 :

1. Green Chemistry, Definition, Green chemistry is defined as invention, design, development, and applications of chemical products, and processes to reduce or to eliminate the use and generation of substances hazardous to human health and, environment., Green Chemistry - Introduction, Green chemistry is also known as sustainable chemistry. The main idea of green chemistry is to, enhance production efficiency, minimize waste generated during the production. Green synthesis must, follow few of the green strategies, such as avoid waste, be atom economic, avoid auxiliary substances, use, catalytic amount of catalyst and recycled, reduce energy requirements and be energy efficient, use, renewable materials and biodegradable materials., , Major Environmental Pollutants, Pollutant is a substance that pollutes something, especially water or the atmosphere. It can enter, the environment naturally, such as from volcanic eruptions, or through human activities, such as burning coal, and gasoline. The major pollutant, theirsources, and their effects on humans and environment are as follows:, 1. Oxides of Carbon (COx ), Types:, Carbon dioxide (CO2), Carbon monoxide (CO), Source of Production:, Combustion of coal, oil and other fuels for energy production, manufacturing, and transport, Biomass burning, Effects on Humans and Environment:, CO2 has a major role in green-house effect, It produces weak carbonic acid adding to acid rains, CO affects human health by binding to haemoglobin, 2. Oxides of sulphur (SOx), Types:, Sulphur dioxide (SO2), Sulphur trioxide (SO3), Sulphate, (SO 4-), Source of Production:, Combustion of sulphur containing fuel (e.g., coal), Petroleum extraction and refining, Paper manufacturing, Municipal incineration, Ore smelting for metal extraction

Page 2 :

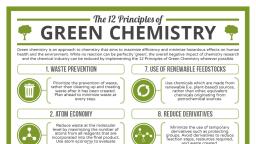

Effects on Humans and Environment:, SO2 cause damage to human and other animal lungs, It is important precursor to acid rain: adverse effects include corrosion of paint, metals and, injury or death to animals and plants., 3. Oxides of Nitrogen (NOx), Types:, Nitrogen oxide (NO), Nitrogen dioxide (N02), Nitrous oxide (N20), Nitrate, (N03-), Source of Production:, Burning of fuels, Biomass burning, By product in the manufacturing of fertilizers Effects on, Humans and Environment:, Form the secondary pollutants: peroxy acetyl nitrate and nitric acid (HNO3), Suppression of plant growth and tissue damage, Cause irritation to eyes, viral infections like influenza, Nitrate form in atmosphere impairs the visibility, Basic Principles of Green Chemistry, Green chemistry is generally based on the 12 principles proposed by Anastas andWarner., Now a days, these 12 principles of green chemistry are considered the fundaments to contribute to, sustainable development., The principles comprise instructions to implement new chemical products, new synthesis, and new, processes.

Page 3 :

Various Green Chemical Approaches, Some of the green chemistry approaches are 1) use of microwave for heating a chemical reaction, 2), use of biocatalysts (i.e., enzymes), 3) Use of phase transfer catalysts, 4) solvent free synthesis, 5) use of, super critical conditions (example: supercritical CO2) of solvents for synthesis, etc., Microwave Synthesis, A microwave is a form of electromagnetic energy, which falls at the lower end of the electromagnetic, spectrum between infrared and radio frequencies., While fire is now rarely used in synthetic chemistry, the Bunsen burner was also replaced by the, mantle, oil bath or hot plate as a source of applying uniform heat to a chemical reaction., Heating chemicals for their reactions by microwave energy is generally referred to as microwaveassisted organic synthesis. It is based on the principle of Dipolar polarization and ionic condution mechanism., Advantages, Microwave heating include following advantages, over the conventional heating:, The difference between microwave energy and other forms of radiation is that microwave energy is, non-ionizing and therefore does not alter the molecular structure of the compounds being heated – it, provides only thermal activation., Microwave-assisted synthes is provides clean synthesis with the advantage of, • Uniform heating, • enhanced reaction rates,, • reduce reaction times,, • higher yields,, • Purity in final product,, • greater selectivity,, • Low operating cost: economic for the synthesis of a large number of organic, molecules,, • Reduction in unwanted side reaction., Bio Catalysed Reactions, Biocatalyst requires enzymes to promote chemical reactions. Enzymes are very efficient, biocatalysts, present in every living organism to carry out a wide range of chemical reactions, and also, finds application as an important tools used in greenchemistry.

Page 4 :

Features of Biocatalysed Reactions, Biocatalysis has many attractive features in the context of green chemistry and sustainable, development:, 1. The catalyst (an enzyme) is derived from renewable resources and is biocompatible (sometimes, even edible), biodegradable, and essentially nonhazardous, that is, it fulfils the criteria of sustainability, remarkably well., 2. Biocatalysis avoids the use of, and contamination of products by, scarce precious metals such as, palladium, platinum, and rhodium., 3. Reactions are performed in an environmentally compatible solvent (water) under mild conditions, (physiological pH and ambient temperature and pressure)., 4. Reactions of multifunctional molecules proceed with high activities and chemo-, regio-, and stereoselectivity and generally without the need for functional group activation, protection, and deprotection steps required in traditional organic syntheses. Biocatalysed reactions are economic and, more efficient in energy and raw material consumption, generate less waste, and are, therefore,, both environmentally and economically more attractive than conventional routes., 5. As a direct result of the higher selectivity and milder reaction conditions, biocatalytic processes, often afford products in higher purity than traditional chemical or chemo-catalytic processes., 6. Enzymatic processes (but not fermentations) can be conducted in standard multipurpose batch, reactors and, hence, do not require any extra investment, for example, for high-pressure equipment., 7. Biocatalytic reactions are conducted under roughly the same conditions of temperature and, pressure, and, hence, it is relatively easy to integrate multiple reactions into eco-efficient catalytic, processes., In short, biocatalysis fits very well with the principles of green chemistry and sustainability., , Solvent Free Reactions or Dry Media Reactions, Avoiding organic solvents during the reactions in organic synthesis leads to a clean, efficient, and, economical technology (green chemistry)., Use of organic solvents is objectionable from the standpoint of environmental hazard. This is why, solvent free reaction conditions are an important object of green chemistry., Examples for the techniques used are mechano-chemical mixing (i.e., grinding), microwave, irradiation, solid/mineral support to the reactants, catalysis by solid surfaces of inexpensive and recyclable, minerals (e.g. alumina, silica, clay, doped clay surface, etc.), Advantages:, A wide variety of industrially important compounds and intermediates such as enones, imines,, enamines and nitroalkenes have been prepared by this environmentally friendly solvent-free approach. In these, reactions, the organic compounds adsorbed on the surface of inorganic oxides, such as alumina, silica and, clay or ‘doped’ supports absorb microwaves whereas the solid support does not absorb or restrict their, transmission. The bulk temperature is relatively low in such solvent free reactions., Synthesis of Adipic Acid by Conventional and Green Route, Chemistry and Uses of Adipic Acid, Chemistry of Adipic Acid, Adipic acid or hexanedioic acid is the organic compound with the formula(CH2)4(COOH)2., IUPAC Name: Hexanedioic acid Molecular, Structure:

Page 5 :

Uses of Adipic Acid, About 60% of the adipic acid produced is used as monomer for the production of nylon by a, polycondensation reaction with hexamethylene diamine forming nylon 66., It is a monomer for production of polyurethane, Its esters are plasticizers, especially in PVC, It has been incorporated into controlled-release formulation matrix tablets to obtain pH-independent, release for both weakly basic and weakly acidic drugs., Small but significant amounts of adipic acid are used as a food ingredient as a flavorant and, gelling aid., Conventional Synthesis of Adipic Acid from Benzene, Step 1: Reduction of benzene to cyclohexane using Raney Ni and hydrogen, , Step 2: Oxidation of cyclohexane to cyclohexanone: Cyclohexane is treated with oxygen in the presence of Co (cobalt), catalyst to obtain cyclohexanone, , Step 3: Oxidation of cyclohexanone to adipic acid: cyclohexanone on oxidation with nitric acid ring opening, reaction takes place to produce adipic acid, , Draw-backs of Conventional Synthesis, Benzene is the starting material for the synthesis of adipic acid. Benzene is carcinogenic and being, VOC (volatile organic compound) it pollutes air. The green chemistry approach now uses glucose as the, starting material for the enzyme catalyzed adipic acid synthesis., 1.6.2 Green Synthesis of Adipic Acid from Glucose, Step 1: Glucose on reaction with Escherichia coli (E.coli) bacteria produces 3- dehydroshikimate

Page 6 :

Step 2: 3-dehydroshikimate on further reaction with E. coli produces Cis-Cis muconic acid, , Step 3: Cis-Cis muconic acid on reduction reaction in the presence of Pt/H2 produces adipic acid, , Synthesis of Paracetamol by Conventional and Green Route, Chemistry and Uses of Paracetamol, Chemistry of Paracetamol, Paracetamol, also known as acetaminophen, is a medication used to treat fever and mild to, moderate pain., IUPAC name: N-(4-hydroxyphenyl)ethanamide, Molecular structure:, , Uses of Paracetamol, It is used as antipyretic drug to reduce body temperature in case of high fever., It is also used as a weak analgesic to reduce the mild to moderate pain (examples: head ache,, tooth pain, menstrual pain, etc.), Conventional Synthesis of Paracetamol from Phenol, Step 1: Nitration reaction of phenol using nitrating mixture (H 2SO4 + HNO3), which is an example for, electrophilic aromatic substitution reaction., p-nitrophenol is more stable than o-nitrophenol as:

Page 7 :

p-nitrophenol can be separated from o-nitrophenol by HPLC (high performance liquid chromatography) or, column chromatography. Only p-nitrophenol is further used for the synthesis of paracetamol., Step 2: Reduction of nitro group (–NO2 group) to amine group (–NH2 group), p-nitrophenol is reduced to p-aminophenol using NH2OH, , Step 3: Nucleophilic addition reaction of p-aminophenol with acetic anhydride (CH3CO-O- OCCH3) in the presence of, sodium acetate (CH3COONa)., , The % atom economy calculated for this synthesis is ≈ 36%, Green Synthesis of Paracetamol from Phenol, Step 1: Phenol reacts with acetic anhydrie in the presence of strong acid like HF to undergo acylation, reaction which is an electrophilic substitution reaction, to produce 4- hydroxyacetophenone., , Step 2: Reaction of aldehydes and ketones with hydroxylamine (NH2OH) gives oximes. 4hydroxyacetophenone reacts with hydroxylamine to give corresponding ketoxime., , Step 3: Oximes in acidic medium (trifluroacetic acid, CF3COOH) undergoes Beckmann rearrangement to, produce substitute amides. Beckmann rearrangement of the above ketoxime gives paracetamol., , The % atom economy calculated for this green synthesis ≈ 58%

Page 8 :

Industrial Applications of Green Chemistry, Chemical industry involves major chemicals, reagents, solvents, catalysts and almost all types of, organic reactions for synthesis of active pharmaceutical substances. Therefore, many chemicals and chemical, processes involved are hazardous, toxic and may show adverse effects on human health, environment, and on, economic growth., Green chemistry approach is responsible for cleaner air, cleaner water, increased safety for workers in, the chemical industry, safer consumer products of all types, saferfood, safer pesticides, etc., Green chemicals either degrades to innocuous products or are recovered for further use; plants, and animals suffer less harm from toxic chemicals in the environment; lower potential for global warming,, ozone depletion, and smog formation, etc., Some of the industrial applications of green chemistry are:, Higher yields for chemical reactions, consuming smaller amounts of feedstock to obtain the same, amount of product, Fewer synthetic steps, often allowing faster manufacturing of products, increasing plant capacity, and, saving energy and water, Reduced waste, eliminating costly remediation, hazardous waste disposal, and end-of-the-pipe, treatments, Allow replacement of a purchased feedstock by a waste product, Better performance so that less product is needed to achieve the same function, Reduced use of petroleum products, slowing their depletion and avoiding their hazards and price, fluctuations, Reduced manufacturing plant size or footprint through increased throughput, Increased consumer sales by earning and displaying a safer-product label (e.g., Safer Choice, labeling), Improved competitiveness of chemical manufacturers and their customers, , 8