Page 1 :

Electrician, , GOVERNMENT OF INDIA, MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP, DIRECTORATE GENERAL OF TRAINING, , COMPETENCY BASED CURRICULUM, , ELECTRICIAN, (Duration: Two Years), , CRAFTSMEN TRAINING SCHEME (CTS), NSQF LEVEL- 5, , SECTOR – POWER

Page 2 :

Electrician, , ELECTRICIAN, (Engineering Trade), (Revised in 2017), Version: 1.1, , CRAFTSMEN TRAINING SCHEME (CTS), NSQF LEVEL- 5, , Developed By, Ministry of Skill Development and Entrepreneurship, Directorate General of Training, , CENTRAL STAFF TRAINING AND RESEARCH INSTITUTE, EN-81, Sector-V, Salt Lake City,, Kolkata – 700 091

Page 6 :

Electrician, , CONTENTS, S No., , Topics, , Page No., , 1., 2., 3., 4., , Course Information, Training System, Job Role, General Information, , 5., , NSQF Level Compliance, , 6., , Learning Outcome, , 10-11, , 7., 8., 9., , Learning Outcome with Assessment Criteria, Trade Syllabus, Syllabus - Core Skill, 9.1 Core Skill – Workshop Calculation & Science, 9.2 Core Skill – Engineering Drawing, 9.3 Core Skill – Employability Skill, Annexure I, List of Trade Tools & Equipment, List of Tools & Equipment for Employability Skill, Annexure II - Format for Internal Assessment, , 12-21, 22-40, , 10., , 11., , 1, 2-5, 6, 7-8, 9, , 41-42, 43-46, 47-50, 51-60, 61, 62

Page 7 :

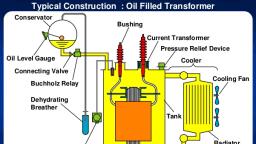

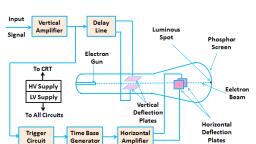

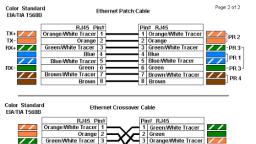

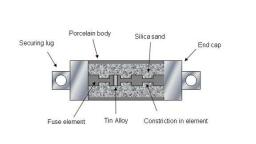

Electrician, , 1. COURSE INFORMATION, During the two years duration of Electrician trade a candidate is trained on professional, skill, professional knowledge, Engineering Drawing, Workshop Calculation & Science and, Employability skill. In addition to this a candidate is entrusted to undertake project work and, extracurricular activities to build up confidence. The Broad components covered professional, skill, subjects are as below:First Year– In this year the trainee learns about safety and environment, use of fire extinguishers,, artificial respiratory resuscitation to begin with. He gets the idea of trade tools & its, standardization, identifies different types of conductors, cables & their skinning & joint making., Basic electrical laws like Kirchhoff’s law, ohm’s law, laws of resistances and their application in, different combinations of electrical circuit are practiced along with laws of magnetism. The, trainee practices on circuit for single phase and poly-phase circuits for 3 wire /4 wire balanced &, unbalanced loads. Skilling practice on different types & combination of cells for operation and, maintenance is being done. Wiring practice with installation of different accessories like ICDP, switch, distribution fuse box and mounting energy meters are practiced as per IE rules for, hostel/residential building, workshop and its fault detection is done by trainee. The trainee will, practice for pipe & plate earthing. Different types of light fitting are to be done like HP/LP, mercury vapour and sodium vapour are prominent. The trainee will practice on different types of, measuring instruments like multimeter, wattmeter, energy meter, phase sequences meter,, frequency meter, for measurement of electrical parameters in single & three phase circuits. He, will gain skill on range extension, calibration and testing of meters. Practice for dismantling,, assembling and testing of heating element equipment, induction heating equipment, grinding, machines and washing machines will be done by trainee. Skill will be gained on transformer for, operation, efficiency, series parallel operation, replacement of transformer oil and combination, of single phase transformers for 3 phase operation. The trainee will practice on winding of small, transformer., Second Year– In this year the trainee will study the details of rotating machines: DC machines,, induction motors, alternators & MG sets and practice on them. The trainee will practice on, determining characteristics, their performance analysis, starting, speed control and reversing, direction of rotation of machines. He will practice on parallel operation & synchronization of, alternators, winding practice and over hauling will be practiced for DC machine and induction, motors.Practices on diodes for bridge rectifier, switching devices & amplifiers by electronic, components, different wave shape generation and testing by CRO is carried out. Designing, control cabinet, assembling control elements and their wiring are to be practiced. Speed control, of AC/DC motors by electronic controller is being practiced. The trainee will practice on testing,, analyzing and repairing of voltage stabilizer, emergency light, battery charger, UPS and inverter., He will gain knowledge of thermal, hydel, solar & wind energy systems. The trainee will practice, on distribution system, domestic service line and accessories & their protection by practicing on, relay and circuit breaker for operation and maintenance., , 1

Page 8 :

Electrician, , 2. TRAINING SYSTEM, 2.1 GENERAL, The Directorate General of Training (DGT) under Ministry of Skill Development &, Entrepreneurship offers a range of vocational training courses catering to the need of different, sectors of economy/ Labour market. The vocational training programmes are delivered under the, aegis of National Council of Vocational Training (NCVT). Craftsman Training Scheme (CTS) and, Apprenticeship Training Scheme (ATS) are two pioneer programmes of NCVT for propagating, vocational training., Electrician trade under CTS is one of the most popular courses delivered nationwide, through network of ITIs. The course is of two years duration. It mainly consists of Domain area, and Core area. The Domain area (Trade Theory & Practical) impart professional skills and, knowledge, while Core area(Workshop Calculation and science, Engineering Drawing and, Employability Skills) impart requisite core skill, knowledge and life skills.After passing out of the, training programme, the trainee is awarded National Trade Certificate (NTC) by NCVT which is, recognized worldwide., , Trainee broadly needs to demonstrate that they are able to:, , , , , , , Read and interpret technical parameters/ documents, plan and organize work processes,, identify necessary materials and tools;, Perform task with due consideration to safety rules, accident prevention regulations and, environmental protection stipulations;, Apply professional skill, knowledge & employability skills while performing jobs., Check the job/ assembly as per drawing for functioning identify and rectify errors in job/, assembly., Document the technical parameters related to the task undertaken., , 2.2 CAREER PROGRESSION PATHWAYS, , , , , , Can appear in 10+2 examination through National Institute of Open Schooling (NIOS) for, acquiring higher secondary certificate and can go further for General/ Technical, education., Can take admission in diploma course in notified branches of Engineering by lateral entry., Can join Apprenticeship programme in different types of industries leading to National, Apprenticeship certificate (NAC)., Can join Crafts Instructor Training Scheme (CITS) in the trade for becoming instructor in, ITIs., 2

Page 9 :

Electrician, , 2.3 COURSE STRUCTURE, Table below depicts the distribution of training hours across various course elements, during a period of two-years: -, , S No., 1, 2, 3, 4, 5, 6, 7, 8, , Course Element, Professional Skill (Trade Practical), Professional Knowledge (Trade Theory), Workshop Calculation & Science, Engineering Drawing, Employability Skills, Library & Extracurricular activities, Project work, Revision & Examination, Total, , Notional Training, Hours, 2184, 504, 168, 252, 110, 142, 320, 480, 4160, , 2.4 ASSESSMENT & CERTIFICATION, The trainee will be tested for his skill, knowledge and attitude during the period of course and, at the end of the training programme as notified by the Govt. of India from time to time. The, employability skills will be tested in first yearitself., a) The Internal Assessment during the period of training will be done by Formative Assessment, Method by testing for assessment criteria listed against learning outcomes.The training institute, have to maintain individual trainee portfolio as detailed in assessment guideline. The marks of, internal assessment will be as per the template (Annexure – II)., b) The final assessment will be in the form of summative assessment method. The All India Trade, Test for awarding NTC will be conducted by NCVT as per the guideline of Govt of India. The, pattern and marking structure is being notified by Govt. of India from time to time. The learning, outcome and assessment criteria will be basis for setting question papers for final assessment., The examiner during final examination will also check individual trainee’s profile as detailed in, assessment guideline before giving marks for practical examination., , 2.4.1 PASS REGULATION, For the purposes of determining the overall result, weightage of 100% is applied for six, months and one year duration courses and 50% weightage is applied to each examination for two, years courses. The minimum pass percent for Practical is 60% & minimum pass percent for, Theory subjects is 33%., 3

Page 10 :

Electrician, , 2.4.2 ASSESSMENT GUIDELINE, Appropriate arrangements should be made to ensure that there will be no artificial, barriers to assessment. The nature of special needs should be taken into account while, undertaking assessment. Due consideration should be given while assessing for teamwork,, avoidance/reduction of scrap/wastage and disposal of scrap/wastage as per procedure,, behavioral attitude, sensitivity to environment and regularity in training. The sensitivity towards, OSHE and self-learning attitude are to be considered while assessing competency., Assessment will be evidence based, comprising the following:, Job carried out in labs/ workshop, Record book/ daily diary, Answer sheet of assessment, Viva-voce, Progress chart, Attendance and punctuality, Assignment, Project work, Evidences of internal assessments are to be preserved until forthcoming examination for, audit and verification by examination body. The following marking pattern to be adopted while, assessing:, Performance Level, , Evidence, , (a) Weightage in the range of 60 -75% to be allotted during assessment, Demonstration of good skill in the use of, hand tools, machine tools and workshop, equipment., 60-70% accuracy achieved while undertaking, different work with those demanded by the, component/job., A fairly good level of neatness and, consistency in the finish., Occasional support in completing the, project/job., , For performance in this grade, the candidate, should produce work which demonstrates, attainment of an acceptable standard of, craftsmanship with occasional guidance, and, due regard for safety procedures and practices., , (b)Weightage in the range of above75% - 90% to be allotted during assessment, Good skill levels in the use of hand tools,, machine tools and workshop equipment., 70-80% accuracy achieved while undertaking, different work with those demanded by the, component/job., , For this grade, a candidate should produce work, which demonstrates attainment of a reasonable, standard of craftsmanship, with little guidance,, and regard for safety procedures and practices., , 4

Page 11 :

Electrician, A good level of neatness and consistency in, the finish, Little support in completing the project/job., (c) Weightage in the range of above 90% to be allotted during assessment, High skill levels in the use of hand tools,, machine tools and workshop equipment., Above 80% accuracy achieved while, undertaking different work with those, demanded by the component/job., A high level of neatness and consistency in, the finish., Minimal or no support in completing the, project., , For performance in this grade, the candidate,, with minimal or no support in organization and, execution and with due regard for safety, procedures and practices, has produced work, which demonstrates attainment of a high, standard of craftsmanship., , 5

Page 12 :

Electrician, , 3. JOB ROLE, Electrician General; installs, maintains and repairs electrical machinery equipment and fittings in, factories, workshops power house, business and residential premises etc. Studies drawings and, other specifications to determine electrical circuit, installation details etc. Positions and installs, electrical motors, transformers, switchgears. Switchboardsand other electrical equipment,, fittings and lighting fixtures. Makes connections and solders terminals. Tests electrical, installations and equipment and locates faults using megger, test lamps etc. Repairs or replaces, defective wiring, burnt out fuses and defective parts and keeps fittings and fixtures in working, order. May do armature winding, draw wires and cables and do simple cable jointing. May, operate, attend and maintain electrical motors, pumps etc., Electrical Fitter; fits and assembles electrical machinery and equipment such as motors,, transformers, generators, switchgears, fans etc., Studies drawings and wiring diagrams of fittings,, wiring and assemblies to be made. Collects prefabricated electrical and mechanical components, according to drawing and wiring diagrams and checks them with gauges, megger etc. to ensure, proper function and accuracy. Fits mechanical components, resistance, insulators, etc., as per, specifications, doing supplementary tooling where necessary. Follows wiring diagrams, makes, electrical connections and solders points as specified. Checks for continuity, resistance, circuit, shorting, leakage, earthing, etc. at each stage of assembly using megger, ammeter, voltmeter and, other appliances and ensures stipulated performance of both mechanical and electrical, components filled in assembly. Erects various equipment such as bus bars, panel boards,, electrical posts, fuse boxes switch gears, meters, relays etc. using non-conductors, insulation, hoisting equipment as necessary for receipt and distribution of electrical current to feeder lines., Installs motors, generators, transformer etc. as per drawings using lifting and hoisting equipment, as necessary, does prescribed electrical wiring, and connects to supply line. Locates faults in case, of breakdown and replaces blown out fuse, burnt coils, switches, conductors etc. as required., Checks, dismantles, repairs and overhauls electrical units periodically or as required according to, scheduled procedure. May test coils. May specialize in repairs of particular equipment, manufacturing, installation or power house work and be designated accordingly., , Reference NCO-2015:, (i) 7411.0100 - Electrician General, (ii) 7412.0200 - Electrical Fitter, , 6

Page 13 :

Electrician, , 4. GENERAL INFORMATION, , Name of the Trade, , Electrician, , NCO - 2015, , 7411.0100, 7412.0200, , NSQF Level, , Level-5, , Duration of Craftsmen, Training, , Two Years, , Entry Qualification, , Passed 10th class examination with Science and Mathematics or its, equivalent., , Unit Strength (No. Of, Student), , 20, , Space Norms, , 98 Sq. metres, , Power Norms, , 5.2 KW (for two units in one shift), , Instructors Qualification for, (i) Electrician Trade, , Degree in Electrical/ Electrical and Electronics Engineering from, recognized Engineering College/ university with one year experience, in the relevant field., OR, Diploma in Electrical/ Electrical and Electronics Engineering from, recognized board of technical education with two years experience, in the relevant field, OR, NTC/NAC passed in "Electrician" trade with three years post, qualification experience in the relevant field., Essential Qualification:, Craft Instructor Certificate in relevant trade under NCVT., , (ii) Workshop, Calculation & Science, , (iii) Engineering Drawing, , Out of two Instructors required for the unit of 2(1+1), one must, have Degree/Diploma and other must have NTC/NAC, qualifications., Degree in Engineering with one year experience., OR, Diploma in Engineering with two years experience., Essential Qualification:, Craft Instructor Certificate in RoD& A course under NCVT., Degree in Engineering with one year experience., OR, 7

Page 14 :

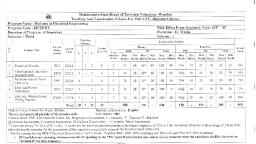

Electrician, Diploma in Engineering with two years experience., OR, NTC/ NAC in the Draughtsman (Mechanical / Civil) with three years, experience., , (iv) Employability Skill, , List of Tools & Equipment, , Essential Qualification:, Craft Instructor Certificate in RoD& A course under NCVT., MBA OR BBA with two years experience OR Graduate in Sociology/, Social Welfare/ Economics with Two years experience OR Graduate/, Diploma with Two years experience and trained in Employability, Skills from DGT institutes., AND, Must have studied English/ Communication Skills and Basic, Computer at 12th / Diploma level and above., OR, Existing Social Studies Instructors duly trained in Employability, Skills from DGT institutes., As per Annexure-I, , Distribution of training on Hourly basis: (Indicative only), Total Hrs, /week, , Trade, Practical, , Trade, Theory, , Workshop, Cal. & Sc., , Engg., Drawing, , Employability, Skills, , ExtraCurricular, Activity, , 40 Hours, , 25 Hours, , 6 Hours, , 2 Hours, , 3 Hours, , 2 Hours, , 2 Hours, , 8

Page 15 :

Electrician, , 5. NSQF LEVEL COMPLIANCE, NSQF level for Electrician trade under CTS: Level 5, As per notification issued by Govt. of India dated- 27.12.2013 on National Skill, Qualification Framework total 10 (Ten) Levels are defined., Each level of the NSQF is associated with a set of descriptors made up of five outcome, statements, which describe in general terms, the minimum knowledge, skills and attributes that, a learner needs to acquire in order to be certified for that level., Each level of the NSQF is described by a statement of learning outcomes in five domains,, known as level descriptors. These five domains are:, a., b., c., d., e., , Process, Professional knowledge, Professional skill, Core skill, Responsibility, , The Broad Learning outcome of Electrician trade under CTS mostly matches with the Level, descriptor at Level- 5., The NSQF level-5 descriptor is given below:, Level, Level 5, , Process Required, Job that requires, well developed, skill, with clear, choice of, procedures in, familiar context, , Professional, Knowledge, knowledge, of facts,, principles,, processes, and general, concepts, in, a field of work, or study., , Professional Skill, , Core Skill, , Responsibility, , a range of, cognitive, and practical, skills required to, accomplish, tasks and, solve problems, by, selecting, and applying, basic methods,, tools, materials, and information, , Desired, mathematical, skill,, understanding, of social,, political, and some skill of, collecting and, organising, information,, communication., , Responsibility for, own work and, learning and, some, responsibility, for other's works, and, learning, , 9

Page 16 :

Electrician, , 6. LEARNING OUTCOME, Learning outcomes are a reflection of total competencies of a trainee and assessment, will be carried out as per the assessment criteria., , 6.1 GENERIC LEARNING OUTCOME, 1., 2., 3., 4., , Apply safe working practices., Comply with environment regulation and housekeeping., Interpret & use company and technical communication, Demonstrate basic mathematical concept and principles to perform practical, operations., 5. Understand and explain basic science in the field of study including simple machine., 6. Read and apply engineering drawing for different application in the field of work., 7. Understand and apply the concept in productivity, quality tools, and labour welfare, legislation in day to day work to improve productivity & quality., 8. Explain energy conservation, global warming and pollution and contribute in day to, day work by optimally using available resources., 9. Explain personnel finance, entrepreneurship and manage/organize related task in, day to day work for personal & societal growth., 10. Utilize basic computer applications and internet to take benefit of IT developments, in the industry., , 6.2 SPECIFIC LEARNING OUTCOME, FIRST YEAR, 11. Prepare profile with an appropriate accuracy as per drawing., 12. Prepare electrical wire joints, carry out soldering, crimping and measure insulation, resistance of underground cable., 13. Verify characteristics of electrical and magnetic circuits., 14. Install, test and maintenance of batteries and solar cell., 15. Estimate, Assemble, install and test wiring system., 16. Plan and prepare Earthing installation., 17. Plan and execute electrical illumination system and test., 18. Select and perform measurements using analog / digital instruments., 19. Perform testing, verify errors and calibrate instruments., 20. Plan and carry out installation, fault detection and repairing of domestic appliances., 21. Execute testing, evaluate performance and maintenance of transformer., , 10

Page 17 :

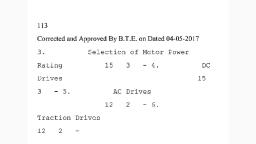

Electrician, SECOND YEAR, 22. Plan, Execute commissioning and evaluate performance of DC machines., 23. Execute testing, and maintenance of DC machines and motor starters., 24. Plan, Execute commissioning and evaluate performance of AC motors., 25. Execute testing, and maintenance of AC motors and starters., 26. Plan, execute testing, evaluate performance and carry out maintenance of, Alternator / MG set., 27. Execute parallel operation of alternators., 28. Distinguish, organise and perform motor winding., 29. Assemble simple electronic circuits and test for functioning., 30. Assemble accessories and carry out wiring of control cabinets and equipment., 31. Perform speed control of AC and DC motors by using solid state devices., 32. Detect the faults and troubleshoot inverter, stabilizer, battery charger, emergency, light and UPS etc., 33. Plan, assemble and install solar panel., 34. Erect overhead domestic service line and outline various power plant layout., 35. Examine the faults and carry out repairing of circuit breakers., , 11

Page 18 :

Electrician, , 7. LEARNING OUTCOME WITH ASSESSMENT CRITERIA, , GENERIC LEARNING OUTCOME, LEARNING OUTCOME, , ASSESSMENT CRITERIA, , 1. Apply safe working, practices, , 1.1 Follow and maintain procedures to achieve a safe working, environment in line with occupational health and safety, regulations and requirements and according to site policy., 1.2 Recognize and report all unsafe situations according to site, policy., 1.3 Identify and take necessary precautions on fire and safety, hazards and report according to site policy and procedures., 1.4 Identify, handle and store / dispose off dangerous goods and, substances according to site policy and procedures following, safety regulations and requirements., 1.5 Identify and observe site policies and procedures in regard to, illness or accident., 1.6 Identify safety alarms accurately., 1.7 Report supervisor/ Competent of authority in the event of, accident or sickness of any staff and record accident details, correctly according to site accident/injury procedures., 1.8 Identify and observe site evacuation procedures according to, site policy., 1.9 Identify Personal Productive Equipment (PPE) and use the, same as per related working environment., 1.10 Identify basic first aid and use them under different, circumstances., 1.11 Identify different fire extinguisher and use the same as per, requirement., , 2. Comply with, environment regulation, and housekeeping, , 2.1 Identify environmental pollution & contribute to the avoidance, of instances of environmental pollution., 2.2 Deploy environmental protection legislation & regulations, 2.3 Take opportunities to use energy and materials in an, environmentally friendly manner., 2.4 Avoid waste and dispose waste as per procedure, 2.5 Recognize different components of 5S and apply the same in, the working environment., , 3. Interpret & use, company and technical, communication, , 3.1 Obtain sources of information and recognize information., 3.2 Use and draw up technical drawings and documents., 3.3 Use documents and technical regulations and occupationally, 12

Page 19 :

Electrician, related provisions., 3.4 Conduct appropriate and target oriented discussions with, higher authority and within the team., 3.5 Present facts and circumstances, possible solutions &use, English special terminology., 3.6 Resolve disputes within the team., 3.7 Conduct written communication., 4. Demonstrate basic, mathematical concept, and principles to, perform practical, operations., , 4.1 Solve different problems like phase angle, etc. with the help of, a calculator., 4.2 Demonstrate conversion of Fraction to Decimal and vice versa., , 5. Understand and explain, basic science in the field, of study including, simple machine., , 5.1 Explain concept of basic science related to the field such as, Material science, Mass, weight, density, speed, velocity, heat &, temperature, force, motion, pressure, heat treatment, centre, of gravity, friction., 5.2 Explain levers and its types., 5.3 Explain relationship between Efficiency, velocity ratio and, Mechanical Advantage., 5.4 Prepare list of appropriate materials by interpreting detail, drawings and determine quantities of such materials., 5.5 Solve simple problems on lifting tackles like crane-Solution of, problems with the aid of vectors., , 6. Read and apply, engineering drawing for, different application in, the field of work., , 6.1 Read & interpret the information on drawings and apply in, executing practical work., 6.2 Read & analyse the specification to ascertain the material, requirement, tools and assembly/maintenance parameters., 6.3 Encounter drawings with missing/unspecified key information, and make own calculations to fill in missing, dimension/parameters to carry out the work., , 7. Understand and apply, the concept in, productivity, quality, tools, and labour, welfare legislation in, day to day work to, improve productivity &, quality., , 7.1 Explain the concept of productivity and quality tools and apply, during execution of job., 7.2 Explain basic concept of labour welfare legislation, adhere to, responsibilities and remain sensitive towards such laws., , 4.3 Explain BCD code, conversion from decimal to binary and viceversa, all other conversions., , 7.3 Knows benefits guaranteed under various acts., , 13

Page 20 :

Electrician, 8. Explain energy, conservation, global, warming and pollution, and contribute in day to, day work by optimally, using available, resources., , 8.1 Explain the concept of energy conservation, global warming,, pollution and utilize the available resources optimally & remain, sensitive to avoid environment pollution., , 9. Explain personnel, finance,, entrepreneurship and, manage/organize, related task in day to, day work for personal &, societal growth., , 9.1 Explain personnel finance and entrepreneurship., 9.2 Explain role of various schemes and institutes for selfemployment i.e. DIC, SIDA, SISI, NSIC, SIDO, Idea for financing/, non-financing support agencies to familiarize with the policies/, programmes, procedure & the available scheme., 9.3 Prepare a report to become an entrepreneur for submission to, financial institutions., , 10. Utilize basic computer, applications and, internet to take benefit, of IT developments in, the industry., , 10.1 Explain the basic hardware of personal computer., 10.2 Use common application software viz., word, excel, power, point etc., in day to day work., 10.3 Awareness about useful internet websites, search relevant, information pertaining to the assigned tasks., , 8.2 Explain standard procedure for disposal of waste., , 14

Page 21 :

Electrician, , SPECIFIC LEARNING OUTCOME, LEARNING OUTCOME, , ASSESSMENT CRITERIA, FIRST YEAR, , 11. Prepare profile with an, appropriate accuracy, as per drawing., , 11.1, , 12. Prepare electrical wire, joints, carry out, soldering, crimping and, measure insulation, resistance of, underground cable., , 12.1, 12.2, , 11.2, 11.3, 11.4, 11.5, 11.6, , 12.3, 12.4, 12.5, 12.6, 12.7, 12.8, 12.9, , 13. Verify characteristics of 13.1, electrical and magnetic 13.2, circuits., 13.3, 13.4, 13.5, 13.6, 13.7, 13.8, 13.9, , Identify the trade tools; demonstrate their uses with safety,, care & maintenance., Prepare a simple half lap joint using firmer chisel with safety., Prepare tray using sheet metal with the safety., Demonstrate fixing of surface mounting type of accessories., Perform connections of electrical accessories., Make and wire up of a test board and test it., Observe safety/ precaution during joints & soldering., Make simple straight twist and rat-tail joints in single strand, conductors., Make married and ‘T’ (Tee) joint in stranded conductors., Prepare a Britannia straight and ‘T’ (Tee) joint in bare, conductors., Prepare western union joint in bare conductor., Solder the finished copper conductor joints with precaution., Prepare termination of cable lugs by using crimping tool., Make straight joint in different types of underground cables., Measure insulation resistance of underground cable., Identify types of wires, cables and verify their specifications., Verify the characteristics of series, parallel and its combination, circuit., Analyze the effect of the short and open in series and parallel, circuits., Verify the relation of voltage components of RLC series circuit, in AC., Determine the power factor by direct and indirect methods in, an AC single phase RLC parallel circuit., Identify the phase sequence of a 3 ø supply using a phasesequence meter., Prepare/ connect a lamp load in star and delta and determine, relationship between line and phase values with precaution., Connect balanced and unbalanced loads in 3 phase star, system and measure the power of 3 phase loads., Make the solenoid and determine its polarity for the given, direction of current., 15

Page 22 :

Electrician, 13.10 Group the given capacitors to get the required capacity and, voltage rating., 14. Install, test and, maintenance of, batteries and solar cell., , 14.1, 14.2, 14.3, 14.4, 14.5, , 15. Estimate, Assemble,, install and test wiring, system., , 15.1, 15.2, 15.3, , 16. Plan and prepare, Earthing installation., , 16.1, , Comply with safety & IE rules when performing the wiring., Prepare and mount the energy meter board., Draw and wire up the consumers main board with ICDP switch, and distribution fuse box., 15.4 Draw and wire up a bank/hostel/jail in PVC conduit., 15.5 Identify the types of fuses their ratings and applications., 15.6 Identify the parts of a relay, MCB & ELCB and check its, operation., 15.7 Estimate the cost of material for wiring in PVC channel for an, office room having 2 lamps, 1 Fan, one 6A socket outlet and, wire up., 15.8 Estimate the requirement for conduit wiring (3 phase) and, wire up., 15.9 Estimate the materials and wire up the lighting circuit for a, godown., 15.10 Estimate the materials and wire up a lighting circuit for a, corridor in conduit., 15.11 Test, locate the fault and repair a domestic wiring installation., , 16.2, 16.3, 16.4, 16.5, 17. Plan and execute, electrical illumination, system and test., , Assemble a DC source 6V/500 mA using 1.5V cells., Determine the internal resistance of cell and make grouping, of cells., Explain charging of battery and test for its condition with, safety/ precaution., Carry out installation and maintenance of batteries., Determine total number of cells required for a given power, requirement., , 17.1, 17.2, , Plan work in compliance with standard safety norms related, with earthing installation., Install the pipe earthing and test it., Install the plate earthing and test it., Measure the earth electrode resistance using earth tester., Carry out earth resistance improvement., Plan work in compliance with standard safety norms related, with electrical illumination system., Install light fitting with reflectors for direct and indirect, lighting., 16

Page 23 :

Electrician, 17.3, 17.4, , 17.6, , Assemble and connect a single twin tube fluorescent light., Connect, install and test the HPMV & HPSV lamp with, accessories., Prepare and test a decorative serial lamp set for 240 V using, 6V bulb and flasher., Install light fitting for show case window lighting., , 18.1, 18.2, 18.3, , Identify the type of electrical instruments., Extend the range of MC voltmeter and ammeter., Measure the frequency by frequency meter., , 18.4, , Measure the power and energy in a single & three phase, circuit using wattmeter and energy meter with CT and PT., , 18.5, , Measure the value of resistance, voltage and current using, digital multimeter., Measure the power factor in poly-phase circuit and verify the, same with voltmeter, ammeter, watt-meter readings., , 17.5, , 18. Select and perform, measurements using, analog / digital, instruments, , 18.6, , 19. Perform testing, verify, errors and calibrate, instruments., , 19.1, 19.2, 19.3, , 20. Plan and carry out, installation, fault, detection and repairing, of domestic appliances., , 20.1, , 21. Execute testing,, evaluate performance, and maintenance of, transformer., , 21.1, , Test single phase energy meter for its errors., Determine the measurement errors while measuring, resistance by voltage drop method., Calibrate the analog multimeter., , Plan work in compliance with standard safety norms related, with domestic appliances., 20.2 Service and Repair of calling bell/ buzzer/ Alarm., 20.3 Service and repair an automatic iron., 20.4 Repair and service of oven having multi-range heat control., 20.5 Replace the heating element in a kettle and test., 20.6 Service and repair an induction heater., 20.7 Service and repair a geyser., 20.8 Service and repair a mixer., 20.9 Service and repair of washing machine., 20.10 Install a pump set., 20.11 Service and repair of table fan., 20.12 Service, repair and install a ceiling fan., , 21.2, 21.3, 21.4, , Plan work in compliance with standard safety norms related, with transformer., Identify the types of transformers and their specifications., Identify the terminals; verify the transformation ratio of a, single phase transformer., Connect and test a single phase auto- transformer., 17

Page 24 :

Electrician, 21.5, , Determine the losses (iron loss and copper loss) and the, regulation of a single phase transformer at different loads., 21.6 Measure the current and voltage using CT and PT., 21.7 Carry out winding for small transformer of 1KVA rating., 21.8 Test the transformer oil with oil testing kit., 21.9 Connect 3 single phase transformers for 3 phase operation of, delta-delta /delta-star /star-star /star-delta., 21.10 Connect the given two single phase transformers in parallel, /series (secondary only) and measure voltage., 21.11 Connect & test 3 phase transformer in parallel., SECOND YEAR, 22. Plan, Execute, commissioning and, evaluate performance, of DC machines., , 22.1, , 22.5, , Plan work in compliance with standard safety norms related, with DC machines., Determine the load performance of a different type of DC, generator on load., Connect, start, run and reverse direction of rotation of, different types of DC motors., Conduct the load performance tests on different type of DC, motor., Control the speed of a DC motor by different method., , 23. Execute testing, and, maintenance of DC, machines and motor, starters., , 23.1, 23.2, 23.3, 23.4, , Test a DC machine for continuity and insulation resistance., Maintenance, troubleshooting & servicing of DC machines., Test armature by using growler., Maintain, service and troubleshoot the DC motor starter., , 24. Plan, Execute, commissioning and, evaluate performance, of AC motors., , 24.1, , Plan work in compliance with standard safety norms related, with AC motors., Draw circuit diagram and connect forward & reverse a 3 phase, squirrel cage induction motor., Start, run and reverse an AC 3 phase squirrel cage induction, motor by different type of starters., Measure the slip of 3 phase squirrel cage induction motor by, tachometer for different output. Draw slip/ load, characteristics of the motor., Determine the efficiency of 3 phase squirrel cage induction, motor by no load test/ blocked rotor test and brake test., Plot the speed torque (Slip/Torque) characteristics of slip ring, induction motor., Demonstrate speed control of 3 phase induction motor., Connect, start and run a 3 phase synchronous motor., Connect start, run, control speed and reverse the DOR of, different type of single phase motors., , 22.2, 22.3, 22.4, , 24.2, 24.3, 24.4, , 24.5, 24.6, 24.7, 24.8, 24.9, , 18

Page 25 :

Electrician, 24.10 Install a single phase AC motor., 25. Execute testing, and, maintenance of AC, motors and starters., , 25.1, , Test continuity and insulation of various AC motors., , 25.2, , Maintain, service and troubleshoot of three phase AC motors., , 25.3, , Maintain, service and troubleshoot of different types of single, phase AC motors., Maintain, service and troubleshoot the AC motor starter., , 25.4, 26. Plan, execute testing,, evaluate performance, and carry out, maintenance of, Alternator / MG set., , 26.1, 26.2, 26.3, 26.4, 26.5, 26.6, 26.7, , 27. Execute parallel, operation of, alternators., , 27.1, , 28. Distinguish, organise, and perform motor, winding., , 28.1, 28.2, , 27.2, , 28.3, 28.4, 28.5, , 29. Assemble simple, electronic circuits and, test for functioning., , 29.1, 29.2, 29.3, 29.4, 29.5, , Plan work in compliance with standard safety norms related, with Alternator & MG set., Connect start and run an alternator and build up the voltage., Determine the load performance of a 3 phase alternator., Start and load a MG set with 3 phase induction motor coupled, to DC shunt generator and build up the voltage., Perform/ Explain alignment of MG set., Preventive and breakdown maintenance of alternator / MG, set., Explain the effect of excitation current in terms of V-curves of, synchronous motor., Demonstrate parallel operation of an alternatorBright lamp, method/ Dark lamp method/ Bright and dark lamp method, Parallel operation of an alternator by using synchroscope., Rewind the field coil /armature winding/ table fan /ceiling fan., Draw winding diagram & rewind a single phase split type, motor (Concentric coil winding)., Drawwinding diagram & rewind a 3 phase squirrel cage, induction motor (single layer distributed winding)., Draw winding diagram & rewind a 3 phase induction motor, (single layer concentric type half coil connection)., Draw winding diagram & rewind a 3 phase squired cage, induction motor. (Double layer distributed type winding), Perform soldering on components/ lug / board with safety., Identify the passive /active components by visual appearance,, code number and test for their condition., Identify the control and functional switches in CRO and, measure the D.C. & A.C. voltage, frequency and time period., Construct and test a half &full wave rectifiers with and, without filter circuits., Construct circuit by using transistor as a switch., 19

Page 26 :

Electrician, 29.6, , Construct and test a UJT as relaxation oscillator & electronic, timer., 29.7 Construct amplifier circuit using Transistor, FET and JFET and, test., 29.8 Construct and test lamp dimmer using TRIAC/DIAC., 29.9 Test IGBT and use in circuit for suitable operation., 29.10 Construct and test the universal motor speed controller using, SCR with safety., 29.11 Construct and test logic gate circuits., 30. Assemble accessories, and carry out wiring of, control cabinets and, equipment., , 30.1, , Draw the layout diagram of 3 phase AC motor control cabinet., , 30.2, , Mount the control elements & wiring accessories on the, control panel., , 30.3, , Carry out wiring in control cabinet for local and remote, control of induction motor., , 30.4, , Draw & wire up the control panel for forward/ reverse, operation of induction motor., , 30.5, 30.6, , Perform wiring for automatic start delta starter., Draw & wire up control panel for sequential motor control for, three motors., Draw & wire up the control panel for a given circuit diagram, and connect the motor., Test the control panel for all the required logics., , 30.7, 30.8, 31. Perform speed control 31.1, of AC and DC motors by 31.2, using solid state, 31.3, devices., , Control the speed of DC motor by using DC drive., Speed control of universal motor by using SCR., Control speed and reverse the direction of rotation of, different type of three phase induction motors using VVVF, control /AC drive, , 32. Detect the faults and, troubleshoot inverter,, stabilizer, battery, charger, emergency, light and UPS etc., , 32.1, 32.2, 32.3, 32.4, 32.5, 32.6, 32.7, , Operation and maintenance of inverter., Troubleshoot and service a voltage stabilizer., Identify the parts, trace the connection and test the DC, regulated power supply with safety., Troubleshoot and service a DC regulated power supply., Test battery charger for its operation., Prepare an emergency light., Carryout maintenance of UPS., , 33. Plan, assemble and, install solar panel., , 33.1, 33.2, 33.3, , Plan work in compliance with solar panel installation norms., Combination of solar cells for given power requirement., Assemble and install solar panel., 20

Page 27 :

Electrician, , 34. Erect overhead, domestic service line, and outline various, power plant layout., , 33.4, , Check the functionality of solar panel., , 34.1, , Prepare single line diagram of thermal/ hydel/ Solar /Wind, power plants., , 34.2, , Prepare layout plan and single line diagram of transmission, line., Draw an overhead and domestic service line., Explain erection ofan overhead service line pole for single, phase 240V distribution system., Identify different type of insulator used in HT and LT line., Fasten jumper in insulators., Connect feeder cable with domestic service line., , 34.3, 34.4, 34.5, 34.6, 34.7, 35. Examine the faults and, carry out repairing of, circuit breakers., , 35.1, 35.2, 35.3, , Prepare layout plan and single line diagram of Distribution, substation., Illustrate application of relays in control circuits and examine, its operation., Identify parts of circuit breaker and check its operation., , 21

Page 28 :

Electrician, , 8. SYLLABUS, SYLLABUS FOR ELECTRICIAN TRADE, FIRST YEAR, Week, No., , Reference Learning, Outcome, , 1, , Apply safe working, practices, , 2, , Apply safe working, practices, Comply, environment, regulation and, housekeeping, , 3, , Prepare profile, with an, appropriate, accuracy as per, drawing., , Professional Skills, (Trade Practical), With Indicative Hours, 1. Visit various sections of the, institutes and location of, electrical installations. (05 hrs), 2. Identify safety symbols and, hazards. (05 Hrs), 3. Preventivemeasures for, electrical accidents and practice, steps to be taken in such, accidents. (05 hrs), 4. Practice safe methods of fire, fighting in case of electrical fire., (05 hrs), 5. Use of fire extinguishers. (05, Hrs), 6. Practice elementary first aid., (05 hrs), 7. Rescue a person and, practiceartificial respiration. (05, Hrs), 8. Disposal procedure of waste, materials. (05 Hrs), 9. Use of personal protective, equipments. (05 hrs), 10. Practice on cleanliness and, procedure to maintain it. (05, hrs), 11. Identify trade tools and, machineries. (10 Hrs), 12. Practice safe methods of lifting, and handling of tools &, equipment. (05 Hrs), 13. Select proper tools for, operation and precautions in, operation. (05 Hrs), 14. Care & maintenance of trade, 22, , Professional Knowledge, (Trade Theory), Scope of the electrician trade., Safety rules and safety signs., Types and working of fire, extinguishers., , First aid safety practice., Hazard identification and, prevention., Personal safety and factory, safety., Response to emergencies e.g., power failure, system failure, and fire etc., , Concept of Standards and, advantages of BIS/ISI., Trade tools specifications., Introduction, to, National, Electrical Code-2011.

Page 29 :

Electrician, , 4-5, , Prepare profile, with an, appropriate, accuracy as per, drawing., , 6-7, , Prepare profile, with an, appropriate, accuracy as per, drawing., , 8, , 9-10, , 11-12, , tools. (05 Hrs), 15. Operations of allied trade tools., (05 Hrs), 16. Workshop practice on filing and, hacksawing. (10Hrs), 17. Prepare hand coil winding, assembly. ( 5 Hrs), 18. Practice on preparing T-joint,, straight joint and dovetail joint, on wooden blocks. (15Hrs), 19. Practice sawing, planing, drilling, and assembling for making a, wooden switchboard. (15Hrs), 20. Practice in marking and cutting, of straight and curved pieces in, metal sheets, making holes,, securing by screw and riveting., (10 Hrs), 21. Workshop practice on drilling,, chipping, internal and external, threading of different sizes., (20Hrs), 22. Practice of making square holes, in crank handle. (5 Hrs), 23. Prepare an open box from, metal sheet. (15 Hrs), , 24. Prepare terminations of cable, Prepare electrical, ends (02 hrs), wire joints, carry, 25. Practice on skinning, twisting, out soldering,, and crimping. (15 Hrs), crimping and, measure insulation 26. Identify various types of cables, and measure conductor size, resistance of, using SWG and micrometer. (8, underground cable., Hrs), 27., Make simple twist, married,, Prepare electrical, Tee and western union joints., wire joints, carry, (18 Hrs), out soldering,, 28., Make britannia straight,, crimping and, britannia Tee and rat tail joints., measure insulation, (18 Hrs), resistance of, 29., Practice in Soldering of joints /, underground cable., lugs. (14 Hrs), 30. Identify various parts, skinning, Prepare electrical, 23, , Allied trades: Introduction to, fitting, tools,, safety, precautions. Description of, files,, hammers,, chisels, hacksaw frames, blades, their, specification and grades., Marking tools description and, use., Types of drills, description &, drilling machines., Various wooden joints., Marking tools; calipers, Dividers, Surface plates,, Angle plates, Scribers,, punches, surface gauges, Types, Uses, Care and, maintenance., Sheet metal tools: Description, of marking & cutting tools., Types of rivets and riveted, joints. Use of thread gauge., Description of carpenter’s, tools Care and maintenance of, tools., Fundamentals of electricity,, definitions, units & effects of, electric current., Conductors and insulators., Conducting materials and their, comparison., , Joints in electrical conductors., Techniques of soldering., Types of solders and flux., , Underground, , cables:

Page 30 :

Electrician, , 13-14, , 15, , wire joints, carry, and dressing of underground, out soldering,, cable. (15 Hrs), crimping and, 31. Make straight joint of different, measure insulation, types of underground cable. (15, resistance of, Hrs), underground cable. 32. Test insulation resistance of, underground cable using, megger. (05 hrs), 33. Test underground cables, forfaults and remove the fault., (15 Hrs), 34. Practice on measurement of, Verify, parameters in combinational, characteristics of, electrical circuit by applying, electrical and, Ohm’s Law for different resistor, magnetic circuits., values and voltage sources and, analyse by drawing graphs. (15, Hrs), 35. Measure current and voltage in, electrical circuits to verify, Kirchhoff’s Law (10 Hrs), 36. Verify laws of series and, parallel circuits with voltage, source in different, combinations. (05Hrs), 37. Measure voltage and current, against individual resistance in, electrical circuit (10 hrs), 38. Measure current and voltage, and analyse the effects of, shorts and opens in series, circuit. (05 Hrs), 39. Measure current and voltage, and analyse the effects of, shorts and opens in parallel, circuit. (05 Hrs), 40. Measure resistance using, Verify, voltage drop method. (5 Hrs), characteristics of, 41. Measure resistance using, electrical and, wheatstone bridge. (5 Hrs), magnetic circuits., 42. Determine the thermal effect of, electric current. (5 Hrs), 43. Determine the change in, resistance due to temperature., 24, , Description, types, various, joints and testing procedure., Cable insulation & voltage, grades, Precautions in using various, types of cables., , Ohm’s Law; Simple electrical, circuits and problems., Kirchoff’s, Laws, and, applications., Series and parallel circuits., Open and short circuits in, series and parallel networks., , Laws of Resistance and various, types of resistors., Wheatstone bridge; principle, and its applications., Effect, of, variation, of, temperature on resistance., Different, methods, of, measuring the values of

Page 31 :

Electrician, (5 Hrs), , 16-17, , Verify, characteristics of, electrical and, magnetic circuits., , 18-19, , Verify, characteristics of, electrical and, magnetic circuits., , 44. Verify the characteristics of, series parallel combination of, resistors. (5 Hrs), 45. Determine the poles and plot, the field of a magnet bar. (08, Hrs), 46. Wind a solenoid and determine, the magnetic effect of electric, current. (06 Hrs), 47. Measure induced emf due to, change in magnetic field. (06, hrs), 48. Determine direction of induced, emf and current. (06 hrs), 49. Practice on generation of, mutually induced emf. (08 hrs), 50. Measure the resistance,, impedance and determine, inductance of choke coils in, different combinations. (06 Hrs), 51. Identify various types of, capacitors, charging /, discharging and testing. (05, Hrs), 52. Group the given capacitors to, get the required capacity and, voltage rating. (05 Hrs), 53. Measure current, voltage and, PF and determine the, characteristics of RL, RC and, RLC in AC series circuits. (08, Hrs), 54. Measure the resonance, frequency in AC series circuit, and determine its effect on the, circuit. (07 hrs), 55. Measure current, voltage and, PF and determine the, characteristics of RL, RC and, RLC in AC parallel circuits. (08, Hrs), 56. Measure the resonance, frequency in AC parallel circuit, 25, , resistance., Series, and, parallel, combinations of resistors., Magnetic terms, magnetic, materials and properties of, magnet., Principles and laws of electromagnetism., Self and mutually induced, EMFs., Electrostatics:, CapacitorDifferent types, functions,, grouping and uses., , Inductive, and, capacitive, reactance, their effect on AC, circuit and related vector, concepts., Comparison and Advantages, of DC and AC systems., Related terms frequency,, Instantaneous value, R.M.S., value Average value, Peak, factor, form factor, power, factor and Impedance etc., Sine wave, phase and phase, difference., Active and Reactive power., Single Phase and three-phase, system.

Page 32 :

Electrician, , 20-21, , 22-23, , and determine its effects on the Problems on A.C. circuits., circuit. (07 hrs), 57. Measure power, energy for, lagging and leading power, factors in single phase circuits, and compare characteristic, graphically. (08 Hrs), 58. Measure Current, voltage,, power, energy and power, factor in three phase circuits., (07 hrs), 59. Practice improvement of PF by, use of capacitor in three phase, circuit.(05 Hrs), 60. Ascertain use of neutral by, Advantages of AC poly-phase, Verify, identifying wires of a 3-phase, system., characteristics of, 4, wire, system, and, find, the, Concept of three-phase Star, electrical and, phase sequence using phase, and Delta connection., magnetic circuits., sequence meter. (10 Hrs), Line and phase voltage,, 61. Determine effect of broken, current and power in a 3, neutral wire in three phase four phase circuits with balanced, wire system.(05 hrs), and unbalanced load., 62. Determine the relationship, Phase sequence meter., between Line and Phase values, for star and delta connections., (10Hrs), 63. Measure the Power of three, phase circuit for balanced and, unbalanced loads. (15 Hrs), 64. Measure current and voltage of, two phases in case of one, phase is short-circuited in, three phase four wire system, and compare with healthy, system.(10 hrs), Project work / Industrial visit, Broad Areas:, a) Prepare and assemble a test board with switches, plug socket, lamp holder etc., b) Temperature controlled system for switching ‘ON’ and ‘OFF’ of any circuit using bimetallic strip., c) Series/ parallel combinational circuits, , 24-26, 27-28, , Revision, Install, test and, maintenance of, , 65. Use of various types of cells., (08 Hrs), 26, , Chemical, current, , effectof electric, and, Laws, of

Page 33 :

Electrician, batteries and solar, cell., , 29-30, , Estimate,, Assemble, install, and test wiring, system., , 31-32, , Estimate,, Assemble, install, and test wiring, system., , 66. Practice on grouping of cells, for specified voltage and, current under different, conditions and care. (12 Hrs), 67. Prepare and practice on, battery charging and details, of charging circuit. (12 Hrs), 68. Practice on routine, care/, maintenance and testing of, batteries. (08 Hrs), 69. Determine the number of, solar cells in series / parallel, for given power requirement., (10 Hrs), , 70. Identify various conduits and, different electrical, accessories. (8 Hrs), 71. Practice cutting, threading of, different sizes & laying, Installations. (17 Hrs), 72. Prepare test boards /, extension boards and mount, accessories like lamp holders,, various switches, sockets,, fuses, relays, MCB, ELCB,, MCCB etc. (25 Hrs), 73. Draw layouts and practice in, PVC Casing-capping, Conduit, wiring with minimum to more, number of points of minimum, 15 mtr length. (15 Hrs), 74. Wire up PVC conduit wiring to, control one lamp from two, different places. (10 Hrs), 75. Wire up PVC conduit wiring to, control one lamp from three, different places. (10 Hrs), 76. Wire up PVC conduit wiring, and practice control of, sockets and lamps in different, 27, , electrolysis., Explanation of Anodes and, cathodes., Types of cells, advantages /, disadvantages, and, their, applications., Lead acid cell; Principle of, operation and components., Types of battery charging,, Safety, precautions,, test, equipment and maintenance., Basic principles of Electroplating, and, cathodic, protection, Grouping of cells for specified, voltage and current., Principle and operation of, solar cell., I.E. rules on electrical wiring., Types of domestic and, industrial wirings., Study of wiring accessories, e.g. switches, fuses, relays,, MCB, ELCB, MCCB etc., Grading of cables and current, ratings., Principle of laying out of, domestic wiring., Voltage drop concept., PVC conduit and Casingcapping wiring system., Different types of wiring Power, control,, Communication and, entertainment wiring., Wiring circuits planning,, permissible load in sub-circuit, and main circuit.

Page 34 :

Electrician, , 33-35, , Estimate,, Assemble, install, and test wiring, system., , 77., , 78., 79., , 80., , 81., , 82., , 36, , Plan and prepare, Earthing, installation., , 83., , 84., , 85., 37-38, , Plan and execute, electrical, illumination system, and test., , 86., , 87., , 88., , 89., , combinations using switching, concepts. (15 Hrs), Wire up the consumers main, board with ICDP switch and, distribution fuse box. (10 Hrs), Prepare and mount the, energy meter board. (10 Hrs), Estimate the cost/bill of, material for wiring of hostel/, residential building and, workshop. (10 Hrs), Practice wiring of hostel and, residential building as per IE, rules. (15 Hrs), Practice wiring of institute, and workshop as per IE rules., (15 Hrs), Practice testing / fault, detection of domestic and, industrial wiring installation, and repair. (15 Hrs), Prepare pipe earthing and, measure earth resistance by, earth tester / megger. (10, Hrs), Prepare plate earthing and, measure earth resistance by, earth tester / megger. (10, Hrs), Test earth leakage by ELCB, and relay. (5 Hrs), Install light fitting with, reflectors for direct and, indirect lighting. (10 Hrs), Group different wattage of, lamps in series for specified, voltage. (5 Hrs), Practice installation of various, lamps e.g. fluorescent tube,, HP mercury vapour, LP, mercury vapour, HP sodium, vapour, LP sodium vapour,, metal halide etc. (18 Hrs), Prepare decorative lamp, 28, , Estimation of load, cable size,, bill of material and cost., Inspection and testing of, wiring installations., Special wiring circuit e.g., godown, tunnel and workshop, etc., , Importance of Earthing., Plate earthing and pipe, earthing methods and IEE, regulations., Earth resistance and earth, leakage circuit breaker., , Laws of Illuminations., Types of illumination system., Illumination factors, intensity, of light., Type of lamps, advantages/, disadvantages and their, applications., Calculations of lumens and, efficiency.

Page 35 :

Electrician, , 90., , 91., 39-40, , Select and perform, measurements, using analog /, digital instruments, , 92., , 93., , 94., , 95., , 96., , 41, , Perform testing,, verify errors and, calibrate, instruments., , 97., , 98., , 99., 42-44, , Plan and carry out, installation, fault, detection and, repairing of, , 100., , circuit using drum switches., (5 Hrs), Prepare decorative lamp, circuit to produce rotating, light effect/running light, effect. (6 Hrs), Install light fitting for show, case lighting. (6 Hrs), Practice on various analog, and digital measuring, Instruments. (5 Hrs), Practice on measuring, instruments in single and, three phase circuits e.g., multi-meter, Wattmeter,, Energy meter, Phase, sequence meter and, Frequency meter etc. (15 Hrs), Measure power in three, phase circuit using two, wattmeter methods. (8 Hrs), Measure power factor in, three phase circuit by using, power factor meter and verify, the same with voltmeter,, ammeter and wattmeter, readings. (12 Hrs), Measure electrical, parameters using tong tester, in three phase circuits. (10, Hrs), Practice for range extension, and calibration of various, measuring instruments. (10, Hrs), Determine errors in, resistance measurement by, voltage drop method. (8 Hrs), Test single phase energy, meter for its errors. (7 Hrs), Dismantle and assemble, electrical parts of various, electrical appliances e.g., cooking range, geyser,, 29, , Classification of electrical, instruments and essential, forces required in indicating, instruments., PMMC and Moving iron, instruments., Measurement, of, various, electrical parameters using, different analog and digital, instruments., Measurement of energy in, three phase circuit., , Errors and corrections in, measurement., Loading effect of voltmeter, and voltage drop effect of, ammeter in circuits., Extension of range and, calibration, of, measuring, instruments., Working principles and circuits, of common domestic, equipment and appliances., Concept of Neutral and Earth.

Page 36 :

Electrician, domestic, appliances., 101., 102., , 103., , 104., 105., 45-46, , Execute testing,, evaluate, performance and, maintenance of, transformer., , 106., , 107., , 108., , 109., , 110., , 47, , Execute testing,, evaluate, performance and, maintenance of, transformer., , 111., , 112., 113., , washing machine and pump, set. (25 Hrs), Service and repair of bell/, buzzer. (5 Hrs), Service and repair of electric, iron, electric kettle, cooking, range and geyser. (12 Hrs), Service and repair of, induction heater and oven., (10 Hrs), Service and repair of mixer, and grinder. (10 Hrs), Service and repair of washing, machine. (13Hrs), Verify terminals, identify, components and calculate, transformation ratio of single, phase transformers. (8 Hrs), Perform OC and SC test to, determine and efficiency of, single phase transformer., (12Hrs), Determine voltage regulation, of single phase transformer at, different loads and power, factors. (12 Hrs), Perform series and parallel, operation of two single phase, transformers. (12 Hrs), Verify the terminals and, accessories of three phase, transformer HT and LT side., (6Hrs), Perform 3 phase operation, (i) delta-delta, (ii) delta-star, (iii) star-star, (iv) star-delta, by use of three single phase, transformers. (6 Hrs), Perform testing of, transformer oil. (6 Hrs), Practice on winding of small, transformer. (8 Hrs), 30, , Working principle,, construction and classification, of transformer., Single phase and three phase, transformers., Turn ratio and e.m.f. equation., Series and parallel operation, of transformer., Voltage Regulation and, efficiency., Auto Transformer and, instrument transformers (CT &, PT)., , Method of connecting three, single phase transformers for, three phase operation., Types of Cooling, protective, devices, bushings and, termination etc., Testing of transformer oil., Materials used for winding, and winding wires in small, transformer.

Page 37 :

Electrician, , 48-49, , 114. Practice of general, maintenance of transformer., (5 Hrs), Project work / Industrial visit, Broad Areas:, a) Overload protection of electrical equipment, b) Automatic control of street light/night lamp, c) Fuse and power failure indicator using relays, d) Door alarm/indicator, e) Decorative light with electrical flasher, , 50-51, , Revision, , 52, , Examination, , Note: 1. Some of the sample project works (indicative only) are given at the mid and end of each year., 2. Instructor may design their own projects and also inputs from local industry may be taken for, designing such new projects., 3. The project should broadly cover maximum skills in the particular trade and must involve some, problem solving skill. Emphasis should be on Teamwork: Knowing the power of synergy/, collaboration, work to be assigned in a group (Group of at least 4 trainees). The group should, demonstrate Planning, Execution, Contribution and Application of Learning. They need to, submit a Project report after completion., 4. If the instructor feels that for execution of specific project more time is required then he may, plan accordingly in appropriate time during the execution of normal trade practical., , 31

Page 38 :

Electrician, , SYLLABUS FOR ELECTRICIAN TRADE, SECOND YEAR, Week, No., , Reference Learning, Outcome, , 53-54, , Plan, Execute, commissioning and, evaluate, performance of DC, machines., , 115., , 116., , 117., , 118., , 119., , 55-56, , 120., Plan, Execute, commissioning and, evaluate, performance of DC, machines., 121., Execute testing,, and maintenance, of DC machines and, motor starters., , 122., , 123., , Professional Skills, (Trade Practical), With Indicative Hours, Identify terminals, parts, and connections of, different types of DC, machines. (10 Hrs), Measure field and, armature resistance of DC, machines. (10 Hrs), Determine build up voltage, of DC shunt generator with, varying field excitation and, performance analysis on, load. (15 Hrs), Test for continuity and, insulation resistance of DC, machine. (5 Hrs), Start, run and, reversedirection of, rotation of DC series, shunt, and compound motors. (10, Hrs), Perform no load and load, test and determine, characteristics of series, and shunt generators. (12, Hrs), Perform no load and load, test and determine, characteristics of, compound generators, (cumulative and, differential). (13 Hrs), Practice dismantling and, assembling in DC shunt, motor. (12 Hrs), Practice dismantling and, assembling in DC, compound generator. (13, 32, , Professional Knowledge, (Trade Theory), General concept of rotating, electrical machines., Principle of DC generator., Use of Armature, Field Coil,, Polarity, Yoke, Cooling Fan,, Commutator, slip ring and, Brushes, Laminated core etc., E.M.F. equation, Separately excited and self, excited generators., Series, shunt and compound, generators., , Armature reaction,, Commutation, inter poles and, connection of inter poles., Parallel Operation of DC, Generators., Load characteristics of DC, generators., Application, losses & efficiency of, DC Generators., Routine & maintenance.

Page 39 :

Electrician, , 57-58, , 59-60, , 61-62, , Hrs), 124., Conduct performance, Plan, Execute, analysis of DC series, shunt, commissioning and, and compound motors. (15, evaluate, Hrs), performance of DC, 125. Dismantle and identify, machines., parts of three point and, Execute testing,, four point DC motor, and maintenance, starters. (10 Hrs), of DC machines and, 126. Assemble, Service and, motor starters., repair three point and four, point DC motor starters., (15 Hrs), 127. Practice maintenance of, carbon brushes, brush, holders, Commutator and, slip-rings. (10 Hrs), 128. Perform speed control of, Execute testing,, DC motors - field and, and maintenance, armature control method., of DC machines and, (10 Hrs), motor starters., 129. Carry out overhauling of, Distinguish,, DC machines. (15 Hrs), organise and, 130. Perform DC machine, perform motor, winding by developing, winding., connection diagram, test, on growler and assemble., (25 Hrs), 131. Identify parts and, Plan, Execute, terminals of three phase, commissioning and, AC motors. (5 Hrs), evaluate, performance of AC 132. Make an internal, connection of automatic, motors., star-delta starter with, Execute testing,, three contactors. (10 Hrs), and maintenance, 133., Connect, start and run, of AC motors and, three phase induction, starters., motors by using DOL, stardelta and auto-transformer, starters. (20 Hrs), 134. Connect, start, run and, reverse direction of, rotation of slip-ring motor, through rotor resistance, 33, , Principle and types of DC motor., Relation between applied voltage, back e.m.f., armature voltage, drop, speed and flux of DC, motor., DC motor Starters, relation, between torque, flux and, armature current., Changing the direction of, rotation., Characteristics, Losses &, Efficiency of DC motors., Routine and maintenance., , Methods of speed control of DC, motors., Lap and wave winding and, related terms., , Working principle of three phase, induction motor., Squirrel Cage Induction motor,, Slip-ring induction motor;, construction, characteristics, Slip, and Torque., Different types of starters for, three phase induction motors, its, necessity, basic contactor circuit,, parts and their functions.

Page 40 :

Electrician, , 63-64, , Plan, Execute, commissioning and, evaluate, performance of AC, motors., Execute testing,, and maintenance, of AC motors and, starters., , 135., , 136., , 137., , 138., , 139., , 65, , Distinguish,, organise and, perform motor, winding., , 140., , 141., , 66-67, , Plan, Execute, commissioning and, evaluate, performance of AC, motors., Execute testing,, and maintenance, of AC motors and, starters., , 142., , 143., , 144., , starter and determine, performance, characteristic. (15 Hrs), Determine the efficiency of, squirrel cage induction, motor by brake test. (8, Hrs), Determine the efficiency of, three phase squirrel cage, induction motor by no load, test and blocked rotor test., (8 Hrs), Measure slip and power, factor to draw speedtorque (slip/torque), characteristics. (14 Hrs), Test for continuity and, insulation resistance of, three phase induction, motors. (5 Hrs), Perform speed control of, three phase induction, motors by various methods, like rheostatic control,, autotransformer etc. (15, Hrs), Perform winding of three, phase AC motor by, developing connection, diagram, test and, assemble. (20 Hrs), Maintain, service and, troubleshoot the AC motor, starter. (05 Hrs), Identify parts and, terminals of different types, of single phase AC motors., (5 Hrs), Install, connect and, determine performance of, single phase AC motors., (15 Hrs), Start, run and reverse the, direction of rotation of, 34, , Single phasing prevention., No load test and blocked rotor, test of induction motor., Losses & efficiency., Various methods of speed, control., Braking system of motor., Maintenance and repair., , Concentric/ distributed, single/, double layer winding and related, terms., , Working principle, different, method of starting and running, of various single phase AC, motors., Domestic and industrial, applications of different single, phase AC motors., Characteristics, losses and, efficiency.

Page 41 :

Electrician, , 145., , 146., , 68-69, , Distinguish,, organise and, perform motor, winding., , 147., , 148., , 149., , 150., , 70-71, , Plan, execute, testing, evaluate, performance and, carry out, maintenance of, Alternator / MG, set., Execute parallel, operation of, alternators., , 151., , 152., , 153., , 154., , 155., , 72, , Plan, execute, testing, evaluate, , 156., , single phase AC motors., (10 Hrs), Practice on speed control, of single phase AC motors., (10 Hrs), Compare starting and, running winding currents, of a capacitor run motor at, various loads and measure, the speed. (10 Hrs), Carry out maintenance,, service and repair of single, phase AC motors. (10 Hrs), Practice on single/double, layer and concentric, winding for AC motors,, testing and assembling. (25, Hrs), Connect, start, run and, reverse the direction of, rotation of universal, motor. (10 Hrs), Carry out maintenance and, servicing of universal, motor. (05 Hrs), Install an alternator,, identify parts and, terminals of alternator. (10, Hrs), Test for continuity and, insulation resistance of, alternator. (5 Hrs), Connect, start and run an, alternator and build up the, voltage. (10 Hrs), Determine the load, performance and voltage, regulation of three phase, alternator. (10 Hrs), Parallel operation and, synchronization of three, phase alternators. (15 Hrs), Install a synchronous, motor, identify its parts, 35, , Concentric/ distributed, single/, double layer winding and related, terms., Troubleshooting of single phase, AC induction motors and, universal motor., , Principle of alternator, e.m.f., equation, relation between, poles, speed and frequency., Types and construction., Efficiency, characteristics,, regulation, phase sequence and, parallel operation., Effect of changing the field, excitation and power factor, correction., , Working principle of synchronous, motor.

Page 42 :

Electrician, performance and, carry out, maintenance of, Alternator / MG, set., , 73, , 74-75, , and terminals. (10 Hrs), 157. Connect, start and plot Vcurves for synchronous, motor under different, excitation and load, conditions. (15 Hrs), 158. Identify parts and, Plan, execute, terminals of MG set. (5, testing, evaluate, Hrs), performance and, 159. Start and load MG set with, carry out, 3 phase induction motor, maintenance of, coupled to DC shunt, Alternator / MG, generator. (20 Hrs), set., Project work/Industrial visit (optional), Broad Areas:, a) Phase sequence checker for 3 phase supply, b) Induction motor protection system, c) Motor starters with protection, d) Solar/wind power generation, , 76-78, , Effect of change of excitation and, load., V and anti V curve., Power factor improvement., , Rotary Converter, MG Set, description and Maintenance., , Revision, , 79, , Assemble simple, electronic circuits, and test for, functioning., , 80-81, , Assemble simple, electronic circuits, and test for, functioning., , 82-83, , Assemble simple, , 160. Determine the value of, resistance by colour code, and identify types. (10 Hrs), 161. Test active and passive, electronic components and, its applications. (15 Hrs), 162. Determine V-I characteristics, of semiconductor diode. (10, Hrs), 163. Construct half wave, full, wave and bridge rectifiers, using semiconductor diode., (10 Hrs), 164. Check transistors for their, functioning by identifying its, type and terminals. (10 Hrs), 165. Bias the transistor and, determine its characteristics., (10 Hrs), 166. Use transistor as an, electronic switch and series, voltage regulator. (10 Hrs), 167. Operate and set the required, 36, , Resistors – colour code, types, and characteristics., Active and passive, components., Atomic structure and, semiconductor theory., P-N junction, classification,, specifications, biasing and, characteristics of diodes., Rectifier circuit - half wave, full, wave, bridge rectifiers and, filters., Principle of operation, types,, characteristics and various, configuration of transistor., Application of transistor as a, switch, voltage regulator and, amplifier., , Basic concept of power

Page 43 :

Electrician, electronic circuits, and test for, functioning., , 84-85, , Assemble simple, electronic circuits, and test for, functioning., , 86-87, , Assemble, accessories and, carry out wiring of, control cabinets, and equipment., , 88-89, , Assemble, accessories and, carry out wiring of, control cabinets, and equipment., , frequency using function, generator. (12 Hrs), 168. Make a printed circuit board, for power supply. (10 Hrs), 169. Construct simple circuits, containing UJT for triggering, and FET as an amplifier. (12, Hrs), 170. Troubleshoot defects in, simple power supplies. (16, Hrs), 171. Construct power control, circuit by SCR, Diac, Triac and, IGBT. (15 Hrs), 172. Construct variable DC, stabilized power supply using, IC. (10 Hrs), 173. Practice on various logics by, use of logic gates and, circuits. (15 Hrs), 174. Generate and demonstrate, wave shapes for voltage and, current of rectifier, single, stage amplifier and oscillator, using CRO. (10 Hrs), 175. Design layout of control, cabinet, assemble control, elements and wiring, accessories for:, (i) Local and remote control of, induction motor. (15 Hrs), (ii) Forward and reverse, operation of induction, motor. (10 Hrs), (iii) Automatic star-delta, starter with change of, direction of rotation. (15 Hrs), (iv) Sequential control of three, motors. (10 Hrs), 176. Carry out wiring of control, cabinet as per wiring, diagram, bunching of XLPE, cables, channeling, tying and, checking etc. (15 Hrs), 37, , electronics devices., IC voltage regulators, Digital Electronics - Binary, numbers, logic gates and, combinational circuits., , Working principle and uses of, oscilloscope., Construction and working of, SCR, DIAC, TRIAC and IGBT., Principle, types and, applications of various, multivibrators., , Study and understand Layout, drawing of control cabinet,, power and control circuits., Various control, elements:Isolators,, pushbuttons, switches,, indicators, MCB, fuses, relays,, timers and limit switches etc., , Wiring accessories: Race ways/, cable channel, DIN rail,, terminal connectors, thimbles,, lugs, ferrules, cable binding, strap, buttons, cable ties,

Page 44 :

Electrician, , 90-91, , Perform speed, control of AC and, DC motors by using, solid state devices., , 92-94, , Detect the faults, and troubleshoot, inverter, stabilizer,, battery charger,, emergency light, and UPS etc., , 95, , Erect, overhead, domestic, service, line and outline, various power plant, layout., , 177. Mount various control, elements e.g. circuit, breakers, relays, contactors, and timers etc. (10 Hrs), 178. Identify and install required, measuring instruments and, sensors in control panel. (10, Hrs), 179. Test the control panel for its, performance. (15 Hrs), 180. Perform speed control of DC, motor using thyristors / DC, drive. (18 Hrs), 181. Perform speed control and, reversing the direction of, rotation of AC motors by, using thyristors / AC drive., (18 Hrs), 182. Construct and test a, universal motor speed, controller using SCR. (14 Hrs), 183. Assemble circuits of voltage, stabilizer and UPS. (15Hrs), 184. Prepare an emergency light., (10 Hrs), 185. Assemble circuits of battery, charger and inverter. (15, Hrs), 186. Test, analyze defects and, repair voltage stabilizer,, emergency light and UPS. (15, Hrs), 187. Maintain, service and, troubleshoot battery charger, and inverter. (10 Hrs), 188. Install an Inverter with, battery and connect it in, domestic wiring for, operation. (10 Hrs), 189. Draw layout of thermal, power plant and identify, function of different layout, elements. (5 Hrs), 190. Draw layout of hydel power, 38, , sleeves, gromats and clips etc., Testing of various control, elements and circuits., , Working, parameters and, applications of AC / DC drive., Speed control of 3 phase, induction motor by using, VVVF/AC Drive., , Basic concept, block diagram, and working of voltage, stabilizer, battery charger,, emergency light, inverter and, UPS., Preventive and breakdown, maintenance., , Conventional and nonconventional sources of energy, and their comparison., Power generation by thermal, and hydel power plants.

Page 45 :

Electrician, , 191., , 192., , 96, , Plan, assemble and 193., install solar panel., Erect, overhead, domestic, service, line and outline 194., various power plant, layout., 195., , 97, , Erect, overhead 196., domestic, service, line and outline, various power plant, 197., layout., , 198., , 199., , 98, , Erect, overhead 200., domestic, service, line and outline, various power plant, 201., layout., , 202., 99, , Examine the faults, , 203., , plant and identify functions, of different layout elements., (5 Hrs), Visit to transmission /, distribution substation. (10, Hrs), Draw actual circuit diagram, of substation visited and, indicate various, components. (5 Hrs), Prepare layout plan and, Identify different elements, of solar power system. (05, Hrs), Prepare layout plan and, Identify different elements, of wind power system. (05, Hrs), Assemble and connect solar, panel for illumination. (15, Hrs), Practice installation of, insulators used in HT/LT line, for a given voltage range. (5, hrs), Draw single line diagram of, transmission and distribution, system. (5 Hrs), Measure current carrying, capacity of conductor for, given power supply. (5 hrs), Fasten jumper in pin, shackle, and suspension type, insulators. (10 Hrs), Erect an overhead service, line pole for single phase, 230V distribution system in, open space. (10 Hrs), Practice on laying of, domestic service line. (10, Hrs), Install bus bar and bus, coupler on LT line. (5 Hrs), Identify various parts of relay, 39, , Various ways of electrical, power generation by nonconventional methods., Power generation by solar and, wind energy., Principle and operation of solar, panel., , Transmission and distribution, networks., Line insulators, overhead poles, and method of joining, aluminum conductors., , Safety precautions and IE rules, pertaining to domestic service, connections., Various substations., Various terms like – maximum, demand, average demand, load, factor, diversity factor, plant, utility factor etc., Types of relays and its

Page 46 :

Electrician, and carry out, repairing of circuit, breakers., , 100101, , and ascertain the operation., (5 Hrs), 204. Practice setting of pick up, current and time setting, multiplier for relayoperation., (5 hrs), 205. Identify the parts of circuit, breaker, check its operation., (5Hrs), 206. Test tripping characteristic of, circuit breaker for over, current and short circuit, current. (5 hrs), 207. Practice on repair and, maintenance of circuit, breaker. (5 hrs), Project work / Industrial visit, Broad Areas:, a) Battery charger/Emergency light, b) Control of motor pump with tank level, c) DC voltage converter using SCRs, d) Logic control circuits using relays, e) Alarm/indicator circuits using sensors, , 102103, , Revision, , 104, , Examination, , operation., Types of circuit breakers, their, applications and functioning., Production of arc and, quenching., , Note: 1. Some of the sample project works (indicative only) are given at the mid and end of each, year., 2. Instructor may design their own projects and also inputs from local industry may be taken, for designing such new projects., 3. The project should broadly cover maximum skills in the particular trade and must involve, some problem solving skill. Emphasis should be on Teamwork: Knowing the power of, synergy/ collaboration, work to be assigned in a group (Group of at least 4 trainees). The, group should demonstrate Planning, Execution, Contribution and Application of Learning., They need to submit a Project report after completion., 4. If the instructor feels that for execution of specific project more time is required then he, may plan accordingly in appropriate time during the execution of normal trade practical., , 40