Page 1 :

TOPIC 2. AGGREGATE., , TOPIC 2:, , AGGREGATE, (10 MARKS)....., , CONTENT:, , , , , , , , , , , , AGGREGATE., REQUIREMENT OF GOOD AGGREGATE., CLASSIFICATION OF AGGREGATE., PROPERTIES OF FINE AGGREGATE., TEST ON FINE AGGREGATE., QUALITY OF FINE SAND., COARSE AGGREGATE., PROPERTES OF COARSE AGGREGATE., GRADING PROPETIES., STRENGTH PARAMETERS OF COARSE AGGREGATE, , CO 2: USE OF RELEVANT AGGREGATE REQUIRED FOR, CONCRETE WORK., CIRRICULAM WEITAGE: 10 MARKS. (16-20 MARKS WITH OR), NO. OF PRATICALS TO BE PERFORMED: = 04, , Determine bulk density of fine and coarse aggregate., Determine fineness modulus of fine aggregate by, sieve analysis., Determine aggregate impact value., Determine aggregate elongation index and flakiness, index, , Page 1

Page 2 :

TOPIC 2. AGGREGATE., , AGGREGATE., DEFINATION: “the material used for manufacturing / preparation of, MORTAR, CONCRETE such as sand, gravel etc. are called as a, aggregate.”, Types of aggregate., FINE AGGREGATE, COARSE AGGREGATE, , 1) FINE AGGREGATE: The aggregate having size less than 4.75 mm is, called as a fine aggregate., Sand comes under the category of fine aggregate., 2) COARSE AGGREGATE: The aggregate having size more than 4.75, mm is called as a coarse aggregate., Khadi / gitti come under the category of coarse aggregate., , Page 2

Page 3 :

TOPIC 2. AGGREGATE., , REQUIREMENT OF GOOD AGGREGATE., The aggregate for good concrete / mortar requires following properties., i., , It must be clean, i.e. free from dirt & dust., , ii., , It should be strong., , iii., , It should be hard., , iv., , It should be durable., , v., , It should not react with cement after mixing, i.e. it should be, chemically inert., , vi., , It should have rough surface, not smooth., , vii., , It should not absorb water more than 5%., , viii., , It should not be soft & porous., , ix., , It should be spherical / cubical in shape., , Page 3

Page 4 :

TOPIC 2. AGGREGATE., , CLASSIFICATION OF AGGREGATES., 1) ACCORDING TO SOURCE / NATURE OF FORMATION., 2) ACCORDING TO SIZE., 3) ACCORDING TO SHAPE., , 1) ACCORDING TO SOURCE / NATURE OF FORMATION:, 1) Naturally occurring aggregates., 2) Artificial / processed aggregates., , 2) ACCORDING TO SIZE:, The aggregates of size less than 4.75mm ARE sieve is called as a fine, aggregate., ( SAND), The aggregates of size more than 4.75mm ARE sieve is called as a, coarse aggregate., 3) ACCORDING TO SHAPE:, Rounded., Irregular., Angular., Flaky., , Page 4

Page 5 :

TOPIC 2. AGGREGATE., , PROPERTIES OF FINE AGGREGATES., PROPERTIES, AGGREGATES, , OF, , FINE, , 1) SIZE., 2) SHAPE., 3) SURFACE TEXTURE., 4) STRENGTH., 5) SPECIFIC GRAVITY., 6) BULK DENSITY., 7) WATER ABSORPTION., 8) SOUNDNESS., 9) SURFACE MOISTURE., 10) BULKING., 11) SPECIFIC SURFACE., 12) SURFACE INDEX., 13) IMPURITIES., A) ORGANIC IMPURITIES., B) INORGANIC IMPURITIES., C) PRESCENCE OF SALT., D) MICA, , Page 5

Page 6 :

TOPIC 2. AGGREGATE., , 1) SIZE OF FINE AGGREGATE., The largest size of fine aggregate is 4.75mm., Mixture of all sizes of fine aggregate will gives us desirable,, economical concrete., For the masonry work, plastering work the cement mortar is prepared, with very fine aggregate of uniform size., , 2) SHAPE OF FINE AGGREGATE., Fine aggregate of irregular nodular shape is preferred instead of, completely rounded grained fine aggregate., , 3) SURFACE TEXTURE OF FINE AGGREGATE., Generally the rough surface aggregate is preferred to smooth aggregate., , 4) STRENGTH OF FINE AGGREGATE., Initially the strength of fine aggregate is cannot ensure the strength of, concrete., , 5) SPECIFIC GRAVITY OF FINE AGGREGATE:, “The specific gravity of aggregate is defined as a ratio of density of, aggregate to density of water.”, This is generally used in the concrete mix design., If it is not given, then take 2.7 as the specific gravity of aggregate is, generally 2.6 to 2.8., , Page 6

Page 7 :

TOPIC 2. AGGREGATE., , 6) BULK DENSITY OF FINE AGGREGATE:, The bulk density is equals of aggregate is considered both the fine, aggregates and the voids between fine aggregates particles., The bulk density of fine aggregate is in between 17-25 kN/m³., , 7) WATER ABSORPTION OF FINE AGGREGATE:, Generally the water absorption for fine aggregate should be kept, minimum UPTO 5%, , 8) SOUNDNESS OF FINE AGGREGATE:, The soundness means expansion / contraction of aggregate when, subjected to temperature variation., A good aggregate should show the minimum expansion / contraction,, under changing temperature., , 9) SURFACE MOISTURE OF FINE AGGREGATE:, Many aggregate have tendency to attract the moisture, & absorb, gives, rise to phenomenon BULKING., , 10) BULKING OF FINE AGGREGATE:, Due to absorption of water/moisture the aggregate swells, this, phenomenon is known as a BULKING., Due to bulking of sand results, the concrete mix design goes wrong., , Page 7

Page 8 :

TOPIC 2. AGGREGATE., , 11) SPECIFIC SURFACE OF FINE AGGREGATE:, The surface area per unit weight of material is called as a specific, surface., , 12) SURFACE INDEX OF FINE AGGREGATE:, It is an empirical number related to specific surface., , 13) IMPURITIES IN FINE AGGREGATE:, A) ORGANIC IMPURITIES., When the sand is from river bed then, it may contain decayed vegetable,, clay, and decayed animal matter., This will affect the setting time & strength of concrete., This is determined by colorimetric test., B) INORGANIC IMPURITIES:, Inorganic impurities may occur in the salt from quarries., These are mainly silt & clay., C) PRESCENCE OF SALT:, The fine aggregate from the tidal river may contain salt which may affect, the setting properties of salt., D) MICA:, The presence of MICA (silicate material) reduces to some extent the, durability of concrete., , Page 8

Page 9 :

TOPIC 2. AGGREGATE., , TEST ON FINE AGGREGATES., 1) DETERMINATION OF FINENESS MODULUS OF SAND &, GRADING OF SAND BY SIEVE ANALYSIS (IS 2386-1963 PART I), 2) SILT CONTENT IN SAND & ITS SPECIFICATION AS PER IS, 383., , 1) DETERMINATION OF FINENESS MODULUS OF SAND &, GRADING OF SAND BY SIEVE ANALYSIS (IS 2386-1963 PART I)., , , TERMS USED IN FINENESS MODULUS:, , 1), , WELL GRADED SAND:, , , , If the aggregate of all the sizes are present in appreciable / EQUAL, percentage the aggregate is termed as a WELL GRADED, AGGREGATE., , , , 4.75 mm, 2.36mm, 1.18mm, 600µ, 300µ, 150µ, 75µ., , , , All sizes fine aggregate are present in equal/ appreciable %, , 2) POORLY GRADED:, If the aggregate of all are of the same sizes then the aggregate is termed, as a POORLY GRADED AGGREGATE., , 3) GAP GRADED:, If the aggregate having the total absence of a particular size of, aggregate, then it is called as a GAP GRADED AGGREGATE., , Page 9

Page 10 :

TOPIC 2. AGGREGATE., , DEFINATION:, FINENESS MODULUS =, , ∑, , The resulting value is FINENESS MODULUS., FINE SAND = 2.2 – 2.6., MEDIUM SAND = 2.6 – 2.9., COARSE SAND = 2.9 – 3.2., The sand having FINENESS MODULUS less than 2.2 or more than, 3.2 is not suitable for the use in concrete., , PROCEDURE TO BRING FM IN THE LIMIT:, To bring the FINENESS MODULUS in limit the cumulative % of, retained sand is increased by adding sand particles which have lesser, % in the calculation., , IMPORTANCE OF FINENESS MODULUS:, Fineness modulus of sand 2.2 to 2.6 is helpful for minimizing voids, ratio & increasing the density of concrete mass., Well graded sand is also useful for good bonding of particles &, strength., , Page, 10

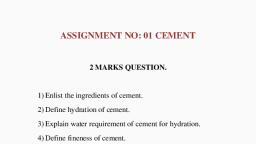

Page 14 :

TOPIC 2. AGGREGATE., , SUMMER -2019, , WINTER -2019, , Page, 14

Page 15 :

TOPIC 2. AGGREGATE., , SILT CONTENT IN SAND & ITS SPECIFICATION AS PER IS 383, , • SILT (गाल) is the very fine particles of size less than 75 microns., • The excessive silt contain in fine aggregate makes it more permeable,, increases shrinkage reduction in the strength., • DEFINITION:• The quantity of silt, fine silt, clay & very fine dust is determined by, SEDIMENTION METHOD/PROCESS., • In this aggregate sample is mixed with water in the measuring jar & the, aggregates are nicely rodded to remove the particles of clay & silt,, which are stuck to aggregates., • PROCEDURE:1) First of all fill the jar up to 50 mm. With water with 1% of common salt., 2) After this add the FINE AGGREGATE in the jar till it reaches 100 ml, mark in jar., 3) After the adding the water & fine aggregates into the jar, shake it well &, keep in the undisturbed condition at least for 3 hrs., 4) After this the silt & clean fine aggregates are settled, respective readings, are taken., , Page, 15

Page 16 :

TOPIC 2. AGGREGATE., , 5) % of silt =, , 𝟑, , × 100 % silt =, , 𝟐, , × 100., , V1= Volume of sample., V2= Volume of silt after 3 hr., • The impurities should not exceed 5% according to IS -383., QUALITY OF FINE AGGREGATE / SAND:1. It should be clean, free from salt, silt, dirt, dust etc., 2. It should be well graded., 3. It should be strong, hard, & durable., 4. It should be chemically inert / inactive., 5. It should have less bulking phenomenon., , Page, 16

Page 17 :

TOPIC 2. AGGREGATE., , BULKING OF FINE AGGREGATE / SAND: DEF:“The free moisture content in fine aggregate results in increasing, volume of sand is called as a bulking / swelling of fine aggregates /, sand.”, This happens especially in rainy seasons, PHENOMENON OF BULKING: Bulking is due to absorption of moisture on individual sand grains in, the form of a thin film., Due to this the sand swells & its volume increases more than the it’s, actual volume. This will increase the bulking to certain limit., After this limit, more moisture causes the breakage of this moisture, film. (SATURATION POINT)., This will cause the sand particles lose the film & sinks into the water., , Page, 17

Page 18 :

TOPIC 2. AGGREGATE., , PROCEDURE:1. Take a simple container and add 2/3 part of sand in it., 2. Measure the exact height of sand using the scale .and notes it down. (Height:H1), 3. Now fill the container up to 2/3 part with water. (Same height of Sand), 4. Now add the measured sand to the container and wait for some time to settle, down., 5. Now calculate the height of Sand in water. (Height:-H2), , Page, 18

Page 19 :

TOPIC 2. AGGREGATE., , EFFECTS OF BULKING ON CONCRETE MIX PROPORTION:1. It affects the properties of concrete., 2. This will leads to harsh concrete with less workability., 3. It will also decrease the productivity of concrete per bag of cement., 4. It will affect the quality of concrete., , CURVE REPRESENTS THE EFFECT OF MOISTURE CONTENT, ON THE BULKING OF SAND:-, , Page, 19

Page 20 :

TOPIC 2. AGGREGATE., , COARSE AGGREGATE., The Aggregate obtained from stone quarries & stone crusher., The size between 4.75 mm to 80 mm is termed as coarse, aggregates., PROPERTIES OF COARSE AGGREGATES., , 1) SIZE OF COARSE AGGREGATE., For the mass concreting works without complicated reinforcement, lager, aggregates of 80mm, 40mm, 20 mm size is used., For ordinary construction of residential / other buildings 20 mm is the, maximum size is used., , 2) SHAPE OF COARSE AGGREGATE., The shape of coarse aggregates is an important factor which affects the, workability & strength of concrete., The angular aggregates are preferred instead of rounded & smooth, aggregates., , Page, 20

Page 21 :

TOPIC 2. AGGREGATE., , 3) SURFACE TEXTURE OF COARSE AGGREGATE., As far as possible the coarse aggregates should have rough surface, texture., A rough surface provides more area for bonding with cement paste &, gives more strength., Smooth textured aggregates can be used for unimportant work., , 4) WATER ABSORPTION OF COARSE AGGREGATE, The water absorption of coarse aggregates is measured by per cent, increase in weight of an oven dry sample after immersion in water for, 24 hrs., More the absorption will affect the both workability & durability of the, concrete., Page, 21

Page 22 :

TOPIC 2. AGGREGATE., , 6) SOUNDNESS OF COARSE AGGREGATE., Soundness is the resistance offered by the Aggregates, to any volume, changes., The average loss of weight should not exceed 12% if tasted with sodium, sulphate & 18% if tasted with magnesium sulphate., , 7) SPECIFIC GRAVITY OF COARSE AGGREGATE., It is the ratio of dry weight of aggregates to the weight of equal volume, of water., , 8) BULK DENSITY OF COARSE AGGREGATE., The ratio of net weight of Aggregate to the volume of Aggregate., , GRADING PROPERTIES: Determination of FM of coarse Aggregates by sieve analysis: This test is similar to sieve analysis of fine Aggregate., In this the aggregates are sieved through a series of sieve 80 mm, 40mm,, 20mm, 10mm, 4.75mm & the weight retained on each sieve is, measured., Form this percentage & respective cumulative percentage for each, sieve is calculated., Thus,, FINENESS MODULUS =, ∑, , Page, 22

Page 24 :

TOPIC 2. AGGREGATE., , Page, 24

Page 25 :

TOPIC 2. AGGREGATE., , STRENGTH PARAMETERS OF COARSE AGGREGATE, Various tests to be conducted on coarse aggregate., DETEMINATION OF CRUSHING VALUE, (IS 2386 part IV-1963), DETEMINATION OF IMPACT VALUE, (IS 2386 part IV-1963), DETEMINATION OF ABRASION VALUE, (IS 2386 part IV-1963), FLAKINESS INDEX OF COARSE AGGREGATE, (IS 2386 part I-1963), ELONGATION INDEX OF COARSE AGGREGATE, (IS 2386 part I-1963), , Page, 25

Page 26 :

TOPIC 2. AGGREGATE., , 1) DETEMINATION OF CRUSHING VALUE (IS 2386 part IV1963), • DEF: Crushing value of aggregates a relative measure of resistance of, an aggregate to crushing under gradually applied crushing load., , Page, 26

Page 27 :

TOPIC 2. AGGREGATE., , PREOCEDURE:, The aggregates passing through 12.5mm sieve & retained on 10mm, sieve is collected., About 6.5kg dry aggregates are filed in standard cylinder in 3 layers., Taming is done with tamping rod for each layer for 25 times& finally, levelled at top surface., For this the weight is found (weight A)., The whole assembly is then kept under compression testing machine, & total weight of 40 tonnes is applied uniformly for 10 minutes., The load is released, the aggregates is taken out & sieved on 2.36mm, sieve. The fraction passing through this 2.36mm sieve is weighted, (weight B)., The aggregates crushing value is given by,, , THE AGGREGATES CRUSHING VALUE =, , X 100 %., , The aggregates crushing value should not be more than 45% for, ordinary concrete., , The crushing value should not be more than 30% for concrete used, for wearing surface such as a runways, roads & pavements., , https://youtu.be/JbAf1DKMxwE YOUTUBE LINK., , Page, 27

Page 29 :

TOPIC 2. AGGREGATE., , 2) DETEMINATION OF IMPACT VALUE (IS 2386 part IV-1963), DEF: This test gives relative measure of resistance of Aggregates to, Suddenly applied load / impact load., , Page, 29

Page 30 :

TOPIC 2. AGGREGATE., , PREOCEDURE:, The aggregates passing through 12.5mm sieve & retained on 10mm, sieve is collected. The aggregates are oven dried at 110°C for 4 hrs., The aggregates are filled in the cup ( WEIGHT-A), By lifting the handle, the hammer is allowed to fall freely on the, aggregates in the cup., Such 15 blows are given to the cup. & Aggregates are taken out of the, cup & sieved on the 2.36mm sieve., The fraction passing through sieve is weighed ( WEIGHT-B), The fraction retained on sieve is also weighed (WEIGHT-C), If (B+C) is less than A by more than 1 gram, then test is discarded &, fresh test is made., The Aggregate impact value is given by,, , THE AGGREGATES IMPACT VALUE =, , X 100 %., , The aggregates impact value should not be more than 45% for, ordinary concrete., , The impact value should not be more than 30% for concrete used for, wearing surface such as a runways, roads & pavements., , https://youtu.be/x4ekpMEERxI YOUTUBE LINK, , Page, 30

Page 31 :

TOPIC 2. AGGREGATE., , 3) DETEMINATION OF ABRASION VALUE (IS 2386 part IV1963), DEF: This test gives relative measure of resistance of Aggregates to, wearing., , Page, 31

Page 32 :

TOPIC 2. AGGREGATE., , PREOCEDURE:, There are 2 methods as per IS code:, i. DEVALATTRITION TEST., ii. LOS ANGELES ABRASION VALUE., But LA test gives more realistic results, it is commonly used., LOS ANGELES ABRASION VALUE:In this method, specific weight of 5kg / 10kg of aggregate is taken & this, aggregate is placed in the cylinder along with abrasive charges., The abrasive charges are specific no of steel balls., The cylinder is rotated at 22 to 33 r.p.m. for 500 /1000 revolutions., The aggregate is removed from cylinder & sieved on 1.7 mm IS sieve., The fraction passing through 1.7mm sieve is expressed as a percentage, of original weight gives the aggregate abrasion value., , .𝟕, , ABRASION VALUE =, , 𝟓, , *100 =%, , The aggregates abrasion value should not be more than 45% for ordinary, concrete., , The abrasion value should not be more than 30% for concrete used for, wearing surface such as a runways, roads & pavements., https://youtu.be/kyxn8sLfPuY YOUTUBE LINK, , Page, 32

Page 33 :

TOPIC 2. AGGREGATE., , 4) FLAKINESS INDEX OF COARSE AGGREGATE (IS 2386, part I-1963), DEF: The flakiness index is the percentage by weight of particle whose, least dimension (thickness) is less than 3/5th of their mean dimension., This test is generally applicable to aggregates larger than 6.3mm size., , Page, 33

Page 34 :

TOPIC 2. AGGREGATE., , PROCEDURE:1) Take W1 quantity of coarse aggregate which should possess at least 200, pieces of any fractions., 2) Sieve this sample through the IS sieve., 3) Now the aggregate retained on the different sieve should be separated., 4) Then each sizes dry aggregate should pass through the corresponding, slot of the thickness gauge., Ex. The aggregate passing through 50mm size & retained on 40 mm, size sieve should pass only through, 𝟓, , 𝟒, 𝟐, , 𝟑, 𝟓, , ) = 27.00mm, , 5) i.e. through 50-40mm slot & if it is passes through it is called as, FLAKY., 6) Now weigh the all the pieces which passes through respective slot i.e., FLAKY (W2), NOW FLAKINESS INDEX =, , 𝟐, , =, , https://youtu.be/2ds0DhrnrtI YOUTUBE LINK, , Page, 34

Page 35 :

TOPIC 2. AGGREGATE., , 5) ELONGATION INDEX OF COARSE AGGREGATE (IS 2386, part I-1963), DEF: The elongation index is the percentage by weight of particle, whose greatest dimension (length) is less than 1.8 times of their mean, dimension., This test is generally applicable to aggregates larger than 6.3mm size., This test is performed at the same time with flakiness test., The elongation index is the total weight of material not passing through, the various slots, which is expressed as a percentage of the total weight of, the sample., , Page, 35

Page 36 :

TOPIC 2. AGGREGATE., , PROCEDURE:1) Sieve the aggregate passing through IS sieve., 2) Pass each aggregate piece through the corresponding a lot of the, gauge/ sieve., 3) Weight the all material retained by length gauge say W3., 4) Now, ELONGATION INDEX = (, , 𝟑, , =, , This test gives us suitability of coarse aggregate w.r.t shape & size., https://youtu.be/5Rks5je9Yuk YOUTUBE LINK, , NECESSITY OF GRADING OF AGGREGATE, &DALETERIOUS MATERIAL IN THE AGGREGATE, NECESSITY OF GRADING OF AGGREGATE :, i., , To make structure dense., , ii., , To prevent honey combing., , iii., , To achieve proper workability., , iv., , To achieve proper finishing., , DALETERIOUS MATERIAL IN THE AGGREGATE :, The various deleterious material materials in aggregates are, Coal, clay, lumps, shale, soft fragment, silt, mica etc., i., , It prevents normal hydration of cement., , ii., , Reduces strength & durability of concrete., , iii., , Prevent good bonding between aggregates & cement., , iv., , Causes efflorescence's., Page, 36

Page 37 :

TOPIC 2. AGGREGATE., , QUESTION BANK., 2 MARKS QUESTION., 01) Define fineness modulus of aggregate., 02) Enlist four shapes of aggregates., 03) Define bulking of sand., 04) What is aggregate impact value?, 05) Define Aggregate crushing value., 06) What is abrasion value of course aggregate?, 07) Define flakiness index., 08) Define elongation index., 09) State the four properties of fine aggregate and coarse aggregate, , 04 MARKS QUESTION., 01) What are the requirements of good aggregate in good concrete?, 02) How is bulking of sand is determined., 03) What is mean by grading of aggregate?, Well graded, Gap graded and, Poor graded, 04) State the properties of fine aggregate and coarse aggregate., 05) Describe the procedure for aggregate impact value test., 06) Describe the Los Angeles abrasion test., 07) How is silt content is determined?, 08) Define Aggregate abrasion value and explain with procedure., 09) Explain the procedure of elongation index and flakiness index., , Page, 37