Page 1 :

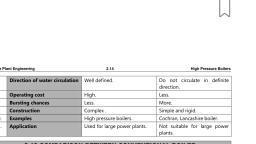

Power Plant Engineering 2.13 High Pressure Boilers, , , , o Fly ash carried away by the flue gas is removed in number of stages:, (i) Firstly, in convection section,, (ii) Secondly, from the bottom of air preheater/economizer and, (iii) Finally, a major portion is removed in dust collectors., © The types of dust collectors used are cyclone, bag filters, electrostatic precipitators etc., , , , 2.11 ADVANTAGES AND DISADVANTAGES OF FLUIDIZED BED COMBUSTION, BOILERS OVER OTHER TYPES OF BOILERS, Advantages of Fluidized Bed Combustion Boilers over Other Types of Boilers:, 1. Low combustion temperatures (820 to 950°C) prevents the formation of nitrogen oxides like nitric, oxide and nitrogen dioxide. Hence, NOx emissions are reduced., 2. Due to low combustion temperatures, fouling and corrosion of tubes is reduced considerably., 3. Due to better heat transfer, the unit size and hence, the capital cost is reduced., 4. The cost of coal crushing is reduced, since it is not necessary to grind the coal to very fine size., 5. This system can respond rapidly to changes in load demand, since, thermal equilibrium between air, and coal particles in the bed is quickly established., 6. There is rapid mixing of fuel particles in the bed, which ensures uniformity of temperature., 7. No moving parts, resulting in reduced maintenance cost., 8, 9., , , , , , , , Safe operation., ). Fully automatic operation., , 10. Efficient operations at temperatures down to 750°C, which is well below the ash fusion temperature., , 11. Easy ash removal system., , 12. Shorter erection and commissioning period., , 13. Higher thermal efficiency., , 14. Combustion with lower excess air, which reduces the fan ratings and power cost., , Disadvantages of Fluidized Bed Combustion Boilers over Other Types of Boilers:, , 1. Since the air had to be supplied at high pressure, so as to support the bed, the fan power is, increased sufficiently., , 2. Problems associated with the distribution of coal and dolomite or limestone occur., , 3. Erosion problems caused by the particles in the furnace, rubbing the evaporator tubes., , 4. Use of this system is limited to relatively low power applications. To obtain larger power, many units, need to be arranged in parallel., , 5. The system requires about 50 % more dolomite and limestone than a flue gas scrubber system for, the sulphur-removal., , , , , , , , , , , , , , , , , , , , 2.12 COMPARISON BETWEEN WATER TUBE AND FIRE TUBE BOILERS, Sr. . . " 4, No. Comparison Aspect Water Tube Boilers Fire Tube Boilers, 1. | Contents in the tube The water circulates inside the | The hot gases from the furnace, tubes, which are surrounded by | pass through the tubes, which, hot gases from the furnace. are surrounded by feed water., 2. Pressure of steam generated | 165 bar (High). 24.5 bar (Low)., 3. _| Rate of steam generated High. Low., 4. | Floor area for given power Less. More., 5. Overall efficiency 90% (High). 75% (Low)., , , , , , , , , , , , contd. ...