Page 1 :

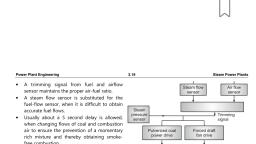

Power Plant Engineering 3.22 Steam Power Plants, , , , , , Due to rejection of heat to the water, steam gets Steam flow mh,, cooled. In other words, temperature of steam Steam line, decreases., , The venturi and thermal sleeve (a high chrome, , steel) protect the main steam pipe from thermal, , shock caused by unvapourized water droplets (if Water ___,, any). flow thy, , The water used for spray must be of high purity,, , so that, no deposits (such as scale) are added on, , the superheater tubes, pipes, and turbine blades. Venturi mixing, Spray type attemperator provides a rapid and, , sensitive means for temperature control., , , , , Thermal sleeve, , Spray nozzle, , , , , , , , , , Total fl, Temperature control of steam is accomplished by (ht th), regulating the amount of spray water. Fig. 3.15 Control of steam temperature by spray, , attemperator, , , , , , , , 3.21.3 Separately Fired Superheater, , , , , , Separately fired furnaces for superheat regulation give a good degree of control over a wide range., The rate of firing is adjusted to obtain a flat steam temperature-load curve., , Application: This system is usually used in the chemical process industry., , Drawback: This system is not generally economical for large electric generating systems., , , , 3.22 MAINTENANCE OF STEAM TURBINES, , , , The maintenance is carried out daily, weekly, monthly and yearly by maintenance department., , , , , , , , 3.22.1 Aims and Objectives of Maintenance, , , , , , Purpose of Maintenance: To maintain the steam turbine in order to achieve as high plant availability as, possible at the minimum cost., , The maintenance of large modem unit must be organised to minimise forced outages (i.e. when the, plant is not running due to any problem), which affects availability., , If the outages are unavoidable, the maintenance work should be planned so that, plant can be put again, to service in the minimum time. This may require round-the-clock working on some activities., , Plant efficiency is also a major aspect of maintenance team. It is the duty of maintenance department to, keep a close communication and working relation with the planning and operation departments in, observing the plant performance., , It is essential to keep a close watch for faults, which are inherent in the design of any equipment of, steam turbine power plant. These are generally known as ‘type faults’., , After careful study, its design may be improved with the help of manufacturing method., , , , 3.22.2 Categories of Inspection Activities, , , , , , , , , , Maintenance of steam turbines used in power station may be classified broadly in three categories. Each, category needs different planning approaches., , Categories of inspection are as follows., , Rectification of defects:, , The defects may or may not be urgent., , If immediate repairs are needed, these may be carried out on running units or the units should be shut, , down. If the repair is not urgent, it may be carried out in planed maintenance programme of future work.