Page 3 :

Bulk Micromachinging, , , Microstructures formed by surface micromachining are thin., , , , For simpler fabrication of microstructures and/or to create larger, vertical space around them etching into the substrate volume would be, required, , , , Thin diaphragms, cavities, and cantilevers can be formed by this, approach., , , , In general silicon etching can be isotropic or anisotropic

Page 4 :

Types of etching, Isotropic etching, , With agitation, , Without agitation, , Anisotropic etching, (111) plane, (100) silicon, , (111), (110) silicon

Page 5 :

Masks for etching of silicon, A photoresist mask will not, survive etchants. Hence a, (SiO2) layer is required for, etch window

Page 6 :

Fabrication of Microsystems, Wafer Cleaning, Deposition, (Evaporation, sputtering, CVD, etc), [Metals, Semiconductors, Dielectrics], Processing of bonded wafer, , Resist processing & Pattern, transfer, , Repeat, for each, new, layer, , Etching, (wet; dry: RIE, DRIE), [Substrate: isotropic, anisotropic; thin films], , Wafer level Bonding, /Packaging, , Microsystems may, require non-electrical, interfaces, Final Packaging,, Testing, , Dicing, Die attach, Release etch, , Required only for, devices with surface, micromachined parts

Page 7 :

Unit processes Required in Bulk Micromachining, , , , , , , Deposition of thin films, , , Physical or Chemical vapor deposition (for metals, polySi, SiO2, Si3N4), , , , Spin coating (for resists, SU-8, other polymeric materials), , Doping, , , To change conductivity of PolySi conducting electrodes, , , , To change chemical (etch rate) characteristics, , Pattern transfer & Etching, , , Lithography, , , , Wet etching of Silicon, , , , Dry Etching of Silicon

Page 8 :

Thin Film Deposition process, , , Source, , , , Transport, , , , Condensation on substrate, , , , The nature of the film deposited depends on process parameters like, substrate, deposition temperature, gaseous environment, rate of, deposition etc., , , , In Physical vapor Deposition (PVD) process, this transfer takes place, by a physical means such as evaporation or impact, , , , , Favorable conditions are created to transfer the material from the source (target), to the destination (substrate)., , In chemical Vapor Deposition (CVD) process films are deposited, through a chemical reaction.

Page 9 :

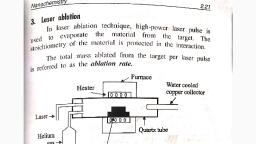

Sputtering, , , A physical phenomenon involving, , , The creation of plasma by discharge of, neutral gas such as helium, , , , Acceleration of ions via a potential, gradient and the bombardment of a, ‘target’ or cathode, , , , , , Through momentum transfer atoms, near the surface of the target metal, become volatile and are transported as, vapors to a substrate, Film grows at the surface of the, substrate via deposition, , Vacuum, enclosure, , Cathode (Target), , Ions, , Sputtered atoms, , Wafer, , Anode, , Vacuum, pump

Page 10 :

Process in CVD, , , Mass transport of reactant (and diluent gases ) in the bulk gases flow region, from the reactor inlet to the deposition zone., , , , Gas phase reactions leading to film precursors and by-products., , , , Mass transport of film pre-cursors and reactants to the growth surface., , , , Adsorption of film precursors and reactants on the growth surface., , , , Mass transport of by-products in the bulk gas flow region away from the, deposition zone towards the reactor exit, , , , Types, , , Plasma enhanced (PECVD), , , , Atmospheric pressure (APCVD), , , , Low pressure (LPCVD), , , , Very low pressure (VLCVD), , , , Metallographic (MOCVD)

Page 12 :

Pattern Transfer Techniques, , , In Lithography, , , , , Resist coating Spin coating Soft baking UV exposure Development Post, baking Etching of thin film Resist striping, , In lift off process a photoresist pattern is generated initially on the substrate, instead of etching the unwanted material., , , The basic criterion for the lift off technique is that the thickness of deposited film should be, significantly less than that of the photoresist and the developed patterns have vertical side, walls., , , , Metal layers with high resolution can be patterned using lift off technique. Metals such as, gold (which can be etched with aqua regia) can be patterned with simple processes by lift, off., Lithography, Thin film, Deposition, , Coating of, Resist, , UV exposure &, Development, , Removal of, unwanted material, , Lift-off, Coating of, Resist, , UV exposure &, Development, , Metal, Deposition, , Removal of resist &, unwanted metal

Page 13 :

Etching of thin films, , , , , , , Silicon Nitride etching, , , 1%HF 60nm/min, , , , 10%HF 500nm/min, , , , H3PO4 10nm/min (180C), , Silicon Dioxide Etching, , , Buffered HF 100-250nm/min, , , , HF (very fast), , Etch rates depends on how the film was deposited (film quality)

Page 14 :

Etching, , , Some definitions, , , Aspect ratio, , , , , , , Selectivity, , , ability of the process to choose between the layer to be removed and the interleaving, layers, , , , (usually 40:1 is required), , Etch rate, , , , , the speed with which the process progresses, , Etch profile, , , , , Ratio of height to lateral dimensions of etched microstructures., , slope of the etch wall, , Wet etching involves, , , Transporting of the reactants by diffusion at the surface, , , , Chemical reaction at the surface, , , , Reaction products transported away from the surface

Page 15 :

Isotropic etching, , , Use acidic etchants, , , , , Rounded patterns formed, , Used for, , , Rounding of sharp edges (formed by anisotropic etching) to avoid stress, concentrations, , , , Removing roughness after dry/anisotropic etching, , , , Thinning→ For creating structures / planar surfaces on single crystal Silicon, , , , Patterning single crystal , poly crystalline or amorphous films, , , , Delineation of electrical junctions and defect evaluation

Page 17 :

Anisotropic etching of Silicon, , , Anisotropic etching means different etch rates in different directions in the material, (e.g., Crystalline Si)

Page 18 :

Anisotropically etched features, (100) wafer with a square mask, , (100), (110), , (110), , SiO2, , 111, , 54.740

Page 19 :

Understanding the Crystallography of Silicon, , , (100), , , , , , (111), , (110)

Page 20 :

Crystal Structure of Silicon, , , Zinc Blende Structure consists of two interpenetrating FCCs, , This is not rotationally symmetric, Properties vary in different directions, , Anisotropic

Page 21 :

Isotropic and Anisotropic etching of Silicon, , [100], , [100], , [110]

Page 22 :

Special Cases, , , (a) If the masking window is misaligned with the crystal directions, the, etch profile is bounded by a superscribing regular geometry., , , , (b) Similar results for non-rectangular etch windows., , , , (c) A free standing cantilever of the masking layer results by, anisotropic etching with aligned geometry shown., , [110], , [110], , [110]

Page 23 :

Bulk micromachining for a cantilever, Top view of substrate, , Side view, , SiO2, Si, , Oxidized silicon wafer, photo, resist, , Photolithography to define cantilever, dimensions and oxide etching, , Oxide etched by BHF, , Cantilever structure

Page 24 :

Cantilevers formed by Bulk etching

Page 26 :

Anisotropic etching Silicon, Etchant, , Temperature, , Etch rate, , Etch rate, , Etch rate, , <100>, , <110 >, , <111>, , KOH:H2O, , 80, , 66, , 132, , 0.33, , KOH, , 75, , 25-42, , 39-66, , 0.5, , EDP, , 110, , 51, , 57, , 1.25, , N2H4:H2O, , 118, , 176, , 99, , 11, , NH4OH, , 75, , 24, , 8, , 1

Page 27 :

Etch variation, , , Silicon etch rate and etched Si surface roughness v/s concentration of, KOH solution and Iso Propyl Alcohol at 75˚C and 900 RPM, stirring, rate.

Page 28 :

Selection of Silicon Crystal Orientation, , (100) Oriented Si, , (110) Oriented Si, , Inward sloping walls (54.74°), , Vertical {1 1 1} walls, , The sloping walls cause a lot of lost real estate, , Narrow trenches with high aspect ratio are possible, , Flat bottom parallel to surface is ideal for, membrane fabrication, , Multifaceted cavity bottom ({110} and, , Bridges perpendicular to a V-groove bound by, (111 ) planes cannot be underetched, , Bridges perpendicular to a V-groove bound by (111), planes can be undercut, , Shape and orientation of diaphragms, convenient and simple to design, , Shape and orientation of diaphragms are awkward, and more difficult to design, , Diaphragm size, bounded by nonetching {111}, planes, is relatively easy to control, , Diaphragm size is difficult to control (the <100> edges, are not defined by nonetching planes), , {100 } planes) makes for a poor diaphragm

Page 29 :

Silicon etching

Page 30 :

Images of Etched geomtries, , SiO2 Mask, , Etched Surface, , Pressure Sensor membrane

Page 31 :

Etch stop technique, , , Etch stop is a region at which the wet etching slows down, , , , Dopant selective etching (DSE), , , Technique is useful for heavily doped layers, leaving behind lightly doped, , , , Advantages of DSE, , , , , , Independent of crystal orientation, , , , Smooth surface finish, , , , Offers possibilities for fabricating release structures with arbitrary lateral geometry, , Disadvantages, , , High boron conc. introduces mechanical stress into the material, , Etchant (Diluent), , Temp. (C), , (100) Etch-rate, (m/min) for boron, doping << 1019cm-3, , Etch-rate (m/min), for boron doping , 1020 cm-3, , EDP (H2O), , 115, , 0.75, , 0.015, , KOH (H2O), , 85, , 1.4, , 0.07, , NaOH (H2O), , 65, , 0.25-1.0, , 0.025-0.1

Page 32 :

Doped regions, , , , , , , , For doping of semiconductors,, controlled quantities of impurity, atoms are introduced into the, selected regions of the surface, through masks on the top of the, wafer., Diffusion and Ion implantation are, common methods for this., Used as etch stop layers, N and P regions can be formed for, active semiconductors, Diffusion, , , , , , , Wafer placed in a high temp furnace, and a carrier gas is passed. Boron and, phosphorous are commonly used, dopants, The deposited wafer is heated in a, furnace for drive in; oxidising or inert, gas to redistribute dopants in the wafer, to desired depth, Silicon dioxide is used as the masking, layer, , Phosphorus Diffusion, Make, , Tempress, , Temperature Range, , 800- 1200 ˚C, , Dopant Source, , POCl3, , Bubbler Gas, , Nitrogen (0.4ltr/min), , Carrier Gas, , Nitrogen (4 ltr/min), , Flow rate of Oxygen, , 0.6 l/min, , Boron Diffusion, Make, , Tempress, , Temperature Range, , 900-1200˚C, , Dopant Source, , Boron Nitride Disc, , Process Ambient, , Nitrogen, , Flow rate of N2, , 4 ltr/min

Page 33 :

Dry Etching Techniques, , , Material removal for IC’s , MEMS, , , By physical, , , , , By chemical, , , , , , , By ion bombardment, Chemical reaction through a reactive species at the surface, , Or Combination, , Plasma etch

Page 34 :

Dry Etching vs Wet Etching, , , Wet Etching, , , , , , , Dry Etching, , No expensive equipment required, , , , Carried out in plasma reactor, , Corrosive Acids or alkalies used, , , , Safe non-toxic gases, e.g. O2 & CF4, used, , , , Waste products are also corrosive, , , , Difficult to automate, , , , Waste products are easily discharged, , , , Limitations in the aspect ratio for, vertical structures, , , , Ease of automation, , , , Extended processes for high aspect, ratio

Page 35 :

Etching Mechanisms in Plasma, (a) Sputtering, , , Physical removal of Si, , , , Very good anisotropy, , , , Poor selectivity, , (b) Chemical Etching, , , Gas phase species react with Si to, form volatile product, , , , Very good selectivity, , , , Poor anisotropy, , +Ion, (a), , Neutral, , Volatile, Product, , Photo, -resist, , (b)

Page 36 :

Etching Mechanisms in Plasma, , (c)Energetic ion-enhanced etching, , , Impinging ions damage surface, increasing, reactivity (Cl2 etching of undoped Si), , , , Good selectivity & anisotropy, , Volatile, + Product, Neutral Ion, , PR, , (d) Inhibitor ion-enhanced etching, , , Requires two different species –etchants, (Cl2) and inhibitors(C2F6), , , , Very good selectivity and anisotropy, , (c), , Neutral, , + Volatile, Ion, Product, , PR, , (d), Inhibitor

Page 37 :

Reactive Ion Etching (RIE), , , , , , Wet etching causes, undercut, Unidirectional etching is, possible with RIE, High fidelity pattern transfer, Steps involved in RIE, Etching, , , 1. Reactive etching species, are generated by electron/, molecule collisions, , , , 2. Etchant species diffuse, through stagnant region to, the surface of the film to be, etched, , , , 3. Etchant species adsorb, onto surface, , , , 4. Reaction takes place, , , , 5. Etched product desorbs, from the surface, , , , 6. Etch products diffuse back, into bulk gas and removed by, vacuum, , http://www.ee.byu.edu/cleanroom/rie_etching.phtml

Page 38 :

Deep Reactive Ion Etching, , , High aspect ratio, deep trench silicon etching process., , , , The principle of the deep trench silicon etching process is an, alternating fluorine based etching and passivation of the structures., , , , Masking layers can be made of photo resist or silicon oxide., , , , The main benefits of the DRIE are:, , , etch rate of up to 6 µm/min, , , , aspect ratio up to 40:1, , , , selectivity to positive resist > 75:1, , , , selectivity to silicon oxide >150:1, , , , etch depth capability 10 to 550 µm (through wafer etching), , , , sidewall profile 90°±1°, , , , feature size 1 to >500 µm

Page 39 :

Deep Reactive Ion Etching (DRIE), , , Process alternates between etching and polymer deposition, , , , SF6/Ar used for etching, , , , CHF3/Ar used for polymerization, , , , Selectivities:photoresist(100:1), SiO2(200:1), , , , Aspect ratio up to 30:1(sidewall angle 90±2o), , , , Etch rates of 2 to 3m/min

Page 40 :

Integration with Electronics, , , CMOS First, , , , MEMS First, , MEMS, Electronics, , Electronics, , MEMS, , , , Notice that in both cases, electronics are integrated on chip, , , , It is also possible to have the electronics in a separate die and, integrate these on a package (Multi-chip modules), , , , Thicker structures and closed cavities can be formed by Wafer, bonding techniques, Cathode, , -, , Glass, , V, , +, Anode, , Silicon

Page 41 :

Fabrication of a Cantilever Beam by Surface Micromachining, Poly layer, , SiO2, , Silicon Substrate, , Deposition of Oxide and, Polysilicon layer, , Top view &Cross sectional view after, patterning the polysilicon layer, , Poly layer, , SiO2, Silicon Substrate, , Top view & Cross sectional view, after Release, , Poly layer, SiO2 anchor, , Silicon Substrate

Page 42 :

Summary: Silicon Micromachining, , , Surface micromachining, , , Surface micro machining (SM) build structures on the surface of the silicon, , , , SM Involves, , , , , , Deposition of thin film of sacrificial & structural layer, Removal of sacrificial layer to release the mechanical structure, , , , Micro structure fabricated using SM are usually planar structure, , , , Dimensions of the SM structures can be several orders of magnitude smaller than bulk, machined structure, , Bulk micromachining, , , Allows selective removal of significant amounts of silicon from a substrate to form, , , , , , , membranes on one side of the wafer, A variety of holes, Or other structures, , BM can be divided into two;, , , Wet etching, , , , , Liquid etchant (aqueous chemicals), , Dry etching, , , Vapor and plasma etchant

Page 43 :

Comparison of Micromachining Techniques, , , Bulk micromachining, , , , Surface micromachining, , , , Emerged during 1960s, , , , Emerged during 1980s, , , , Used pressure sensors, Si valves, , , , , , Used to realize structures within bulk of, a single crystal Si wafer by selectively, removing wafer material, , Structures are mainly located on the, surface of the Si wafer and consists of, thin films, , , , Structures may have thickness range, from sub-micron to full wafer thickness,, and lateral dimensions as large as few, mm, , The dimensions of these structures are, several orders of magnitude smaller, than structures generated by bulk, micromachining, , , , Involves, , , , , , Key step is etching, , , , , , Wet isotropic, Wet anisotropic, Plasma isotropic, Reactive ion etching, , , , , , Deposition of sacrificial layer, Deposition and selective etching of, structural layer(s), Removal of sacrificial layer

Page 44 :

High Aspect Ratio Microsystems, , , Wafer Bonding techniques, , , , High Aspect Ratio Methods for Silicon, , , , LIGA and other molding techniques, , , , Polymeric microsystems (low cost fabrication), , , , Low Temperature Co-fired Ceramics (LTCC)