Page 1 :

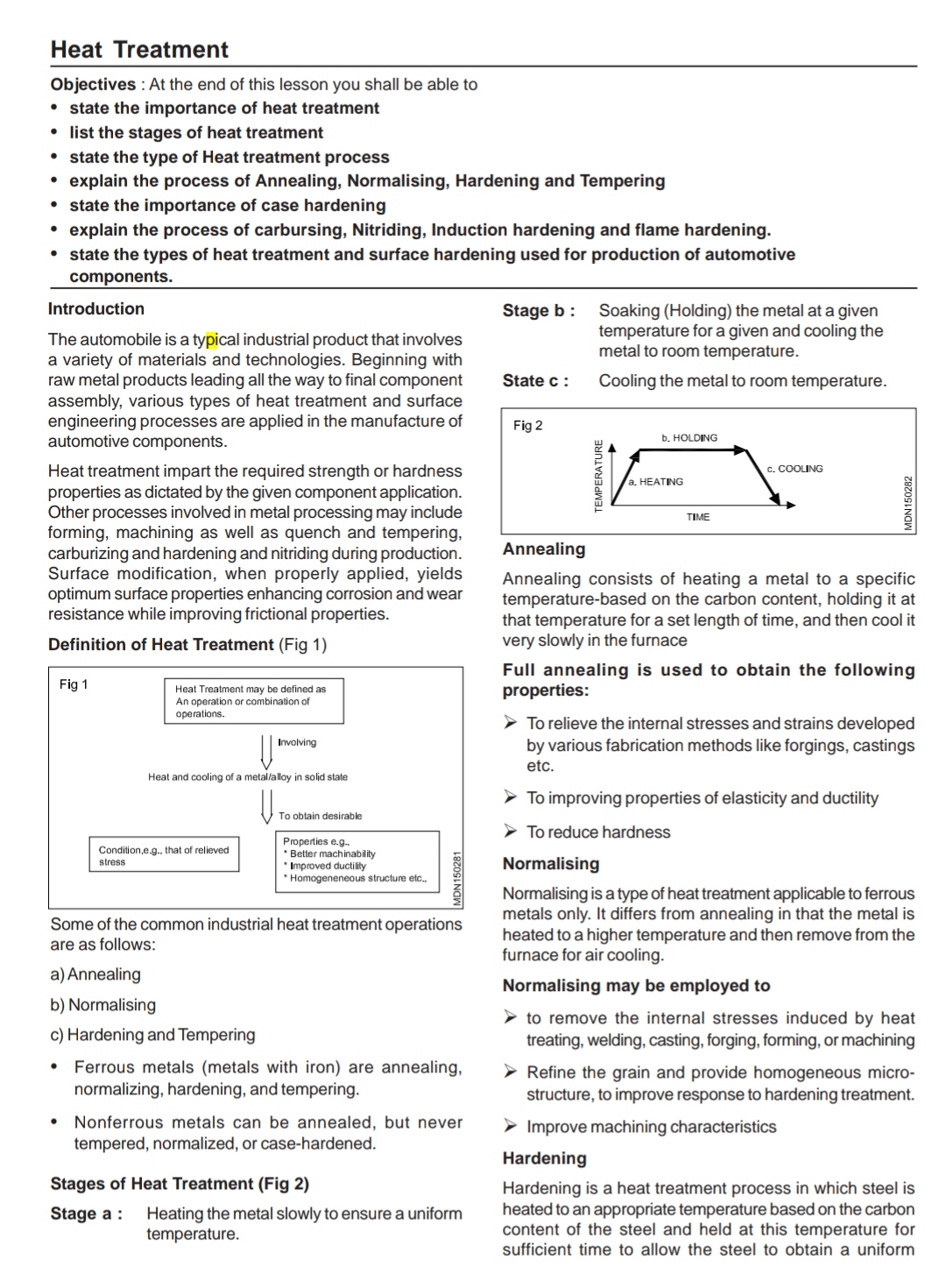

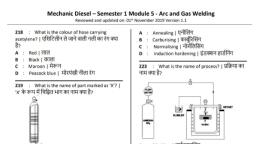

Heat Treatment, , Objectives : At the end of this lesson you shall be able to, * state the importance of heat treatment, , * list the stages of heat treatment, , * state the type of Heat treatment process, , * explain the process of Annealing, Normalising, Hardening and Tempering, , * state the importance of case hardening, , explain the process of carbursing, Nitriding, Induction hardening and flame hardening., state the types of heat treatment and surface hardening used for production of automotive, , , , , , , , , , , , components., Introduction Stage b: Soaking (Holding) the metal at a given, The automobile is a typical industrial product that involves Pend a a el and cooling the, a variety of materials and technologies. Beginning with mee orem temperate:, raw metal products leading all the way to final component Statec: Cooling the metal to room temperature., assembly, various types of heat treatment and surface, engineering processes are applied in the manufacture of Fig 2, automotive components. y b-HOLOING, Heat treatment impart the required strength or hardness g Guana 7, properties as dictated by the given component application. 2 gs, Other processes involved in metal processing may include a TIME z, forming, machining as well as quench and tempering, = =, carburizing and hardening and nitriding during production. Annealing, , Surface modification, when properly applied, yields, optimum surface properties enhancing corrosion and wear, resistance while improving frictional properties., , Definition of Heat Treatment (Fig 1), , , , , , Fig Heat Treatment may be defined as, ‘An operation or combination of, , operations., , , , , , , , Involving, , Heat and cooling of a metalialloy in solid state, , \ To oblain desirable, , , , , , Properties e.9., * Better machinabilty, , * Improved ductity, , * Homogeneneous structure etc,, , Condiion.e.g.. that of relieved, stress., , , , , , , , , , , , , , , , , , MON 150281, , , , Some of the common industrial heat treatment operations, are as follows:, , a) Annealing, b) Normalising, c) Hardening and Tempering, , * Ferrous metals (metals with iron) are annealing,, normalizing, hardening, and tempering., , * Nonferrous metals can be annealed, but never, tempered, normalized, or case-hardened., Stages of Heat Treatment (Fig 2), , Stage a: Heating the metal slowly to ensure a uniform, , temperature., , Annealing consists of heating a metal to a specific, temperature-based on the carbon content, holding it at, that temperature for a set length of time, and then cool it, very slowly in the furnace, , Full annealing is used to obtain the following, properties:, , > Torelieve the internal stresses and strains developed, by various fabrication methods like forgings, castings, etc., , > To improving properties of elasticity and ductility, > Toreduce hardness, Normalising, , Normalising is a type of heat treatment applicable to ferrous, metals only. It differs from annealing in that the metal is, heated to a higher temperature and then remove from the, furnace for air cooling., , Normalising may be employed to, , > to remove the internal stresses induced by heat, treating, welding, casting, forging, forming, or machining, , > Refine the grain and provide homogeneous microstructure, to improve response to hardening treatment., , > Improve machining characteristics, Hardening, , Hardening is a heat treatment process in which steel is, heated to an appropriate temperature based on the carbon, content of the steel and held at this temperature for, sufficient time to allow the steel to obtain a uniform