Page 1 :

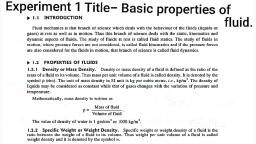

cos, vis228 the Viscosity, , of, yeni, , , , science that concerns with the flow of jj, OW. OF liguids and <fZ, , ‘f js the $ ee, | (} 1 ., prion 050 Study of flow properties of liquids is, pm enacists working in the manufacture of several dos 'S ImporF Ti on creams and pastes. These gen, i§ flow behaviour when exposed-to-different: stress co sms, P jowing situations. pu Coben —_, e _, , ycture Of. dosage, forms ) Materials undergo processes such, Cc., , vy Manufacture ;, () 1 xing, flowing through pipes, filling into the contdine, rlow related changes influence the selection of mixing saies ., i) Handling of drugs for adminiration : The syringibility of the, medicines, the pouring of the liquids from containers, extrusion, of ointment from tubes, all depend on the changes in flow, behaviour of dosage forms., ur of liquids (on applying stress) is of great, Performance of a product depends on the net, ses. Therefore, flow properties, s to maintain the superiority of, ¢ example, dextran, g the viscosity, , Thus, flow behavio, feance in pharmacy., fect of all the above mentioned proces, tused as important quality control tool, product and reduce batch to batch variations. Fo!, lad dextran 110 injections are analysed by determinin, , los at 37°C (P.)., , —- on deformation of solids is, ft ia principles of theology, haters 19 ions in the design of dosage forms, and 11 for suspensions and emulsions,, , beyond the scope ©, re discuss, will be, respectively

Page 2 :

co OF, exeseh MIME i, Ve, y/ con ig resistaner of tO, , 6 19 Siig EEX N greater.is the resistance 1, 1%, A iquid ht a, , TB ca GU cyrup (sucrose Solution), are, , i honeys os alcohol. Syrup has . me, the molecular level, 1...", , wlyof a sy™, , p at lower rate than for, iT, , Fe, , rw, i —_ understand the concept of Visepe, , isti lel | 1, = . + consisting of paral ayers, “ions | pack of beard as shown in Figure 7-1a. = Oy, deck © G, , , , wigs — sa, Th, (a) Liquid at rest (b) Stress induced changes, , 4. Pictorial representation of liquid at rest (a) and, , Figure 7~ es, uced on application of shear stress (b)., , the changes prod, , When pressure is applied horizontally on the top layer ‘A’, the lig..., , ‘begins to flow. It assumes the shape shown in Figure 7-1b. Am, , indicate the magnitude of flow velocity. Since force is applied «@, *, , top layer (A), it moves at greater velocity. While moving ahead, ef, layer (A) induces flow in the second layer (B). The velocity a!, teainlt (B) is somewhat less than that of the first lye |, velocity of fea drag offered by the third layer (C). sini, ird layer (C) is less than that of the second layet, , but hi, - oe ie = of the fourth layer (D). This phenomend mal, hen force j yer (N) remains stationary. Thus, liquids, , 1s appli : ‘ ;, Viscosity, Pplied. This resistance is estimated and ext, Th, ns, , Te representation o: ., liquia from one Siven in Figure 7-1 mimics the port ih,, €r towards the wall of the pipe, when !! "