Page 1 :

ELECTRICIAN, NSQF (LEVEL - 5), , 4th Semester, TRADE THEORY, SECTOR: Electrical, , DIRECTORATE GENERAL OF TRAINING, MINISTRY OF SKILL DEVELOPMENT & ENTREPRENEURSHIP, GOVERNMENT OF INDIA, , NATIONAL INSTRUCTIONAL, MEDIA INSTITUTE, CHENNAI, Post Box No. 3142, CTI Campus, Guindy, Chennai - 600 032, (i), , Copyright @ NIMI Not to be Republished

Page 2 : Sector, , : Electrical, , Duration : 2 - Years, Trade, , : Electrician 4th Semester - Trade Theory - NSQF (LEVEL - 5), , Copyright@2018 National Instructional Media Institute, Chennai, First Edition :, , December 2018, , Copies : 10,000, , Rs.260/-, , All rights reserved., No part of this publication can be reproduced or transmitted in any form or by any means, electronic or mechanical, including, photocopy, recording or any information storage and retrieval system, without permission in writing from the National, Instructional Media Institute, Chennai., , Published by:, NATIONAL INSTRUCTIONAL MEDIA INSTITUTE, P. B. No.3142, CTI Campus, Guindy Industrial Estate,, Guindy, Chennai - 600 032., Phone : 044 - 2250 0248, 2250 0657, 2250 2421, Fax : 91 - 44 - 2250 0791, email :

[email protected],

[email protected], Website: www.nimi.gov.in, , (ii), , Copyright @ NIMI Not to be Republished

Page 3 :

FOREWORD, The Government of India has set an ambitious target of imparting skills to 30 crores people, one out of, every four Indians, by 2020 to help them secure jobs as part of the National Skills Development Policy., Industrial Training Institutes (ITIs) play a vital role in this process especially in terms of providing skilled, manpower. Keeping this in mind, and for providing the current industry relevant skill training to Trainees,, ITI syllabus has been recently updated with the help of Mentor Councils comprising of various stakeholder's, viz. Industries, Entrepreneurs, Academicians and representatives from ITIs., National Instructional Media Institute (NIMI), Chennai has come up with instructional material to suit the, revised curriculum for Electrician 4th Semester Trade Theory NSQF (LEVEL - 5) in Electrical sector, under Semester Pattern required for ITIs and related institutions imparting skill development. The, NSQF (LEVEL - 5) will help the trainees to get an international equivalency standard where their skill, proficiency and competency will be duly recognized across the globe and this will also increase the, scope of recognition of prior learning. NSQF (LEVEL - 5) trainees will also get the opportunities to promote, life long learning and skill development. I have no doubt that with NSQF (LEVEL - 5) the trainers and, trainees of ITIs, and all stakeholders will derive maximum benefits from these IMPs and that NIMI's effort, will go a long way in improving the quality of Vocational training in the country., The Executive Director & Staff of NIMI and members of Media Development Committee deserve appreciation, for their contribution in bringing out this publication., Jai Hind, , RAJESH AGGARWAL, , Director General / Addl. Secretary,, Ministry of Skill Development & Entrepreneurship,, Government of India., , New Delhi - 110 001, , (iii), , Copyright @ NIMI Not to be Republished

Page 4 :

PREFACE, The National Instructional Media Institute (NIMI) was established in 1986 at Chennai by then Directorate, General of Training (D.G.T), Ministry of Labour and Employment, (now under Directorate General of Training, (D.G.T), Ministry of Skill Development and Entrepreneurship) (MSDE) Government of India, with technical, assistance from the Govt. of the Federal Republic of Germany. The prime objective of this institute is to, develop and provide instructional materials for various trades as per the prescribed syllabi (NSQF) under, the Craftsman and Apprenticeship Training Schemes., The instructional materials are created keeping in mind, the main objective of Vocational Training under, NCVT/NAC in India, which is to help an individual to master skills to do a job. The instructional materials, are generated in the form of Instructional Media Packages (IMPs). An IMP consists of Theory book,, Practical book, Test and Assignment book, Instructor Guide, Audio Visual Aid (Wall charts and, Transparencies) and other supporting materials., The trade theory book provides related theoretical knowledge required to enable the trainee to do a job., The test and assignments will enable the instructor to give assignments for the evaluation of the performance, of a trainee. The wall charts and transparencies are unique, as they not only help the instructor to effectively, present a topic but also help him to assess the trainee's understanding. The instructor guide enables the, instructor to plan his schedule of instruction, plan the raw material requirements, day to day lessons and, demonstrations., IMPs also deals with the complex skills required to be developed for effective team work. Necessary care, has also been taken to include important skill areas of allied trades as prescribed in the syllabus., The availability of a complete Instructional Media Package in an institute helps both the trainer and, management to impart effective training., The IMPs are the outcome of collective efforts of the staff members of NIMI and the members of the Media, Development Committees specially drawn from Public and Private sector industries, various training institutes, under the Directorate General of Training (DGT), Government and Private ITIs., NIMI would like to take this opportunity to convey sincere thanks to the Directors of Employment &, Training of various State Governments, Training Departments of Industries both in the Public and Private, sectors, Officers of DGT and DGT field institutes, proof readers, individual media developers and coordinators,, but for whose active support NIMI would not have been able to bring out this materials., , R. P. DHINGRA, EXECUTIVE DIRECTOR, , Chennai - 600 032, , (iv), , Copyright @ NIMI Not to be Republished

Page 6 :

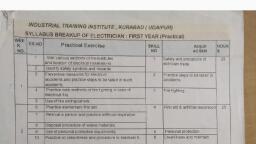

INTRODUCTION, This manual for trade Theory is intended for use in the ITI class room. It consists of a series of lessons that are, to be completed by the trainees during the Third semester of course is the Electrician trade under Electrical, Sector. It is National Skills Qualifications Framework NSQF (LEVEL - 5), supplemented and supported by, instructions/information to assist the trainees in performing the exercises. The syllabus for the, 4th Semester Electrician NSQF (LEVEL - 5) Trade under Electrical Sector Trade Practical is divided into, Seven modules.The allocation of time for the various modules is given below:, Module 1 - Electronic Practice, , 15 Exercises, , 175 Hrs, , Module 2 - Control Panel Wiring, , 5 Exercises, , 100 Hrs, , Module 3 - AC/DC Motor Drives, , 3 Exercises, , 50 Hrs, , Module 4 - Inverter and UPS, , 6 Exercises, , 75 Hrs, , Module 5 - Power Generation and Substation, , 7 Exercises, , 50 Hrs, , Module 6 - Transmission and Distribution, , 7 Exercises, , 50 Hrs, , Module 7 - Circuit Breakers and Relays, , 5 Exercises, , 25 Hrs, , 48 Exercises, , 525 Hrs, , Total, , The syllabus and the content in the modules are interlinked. As the number of workstations available in the, electrical section is limited by the machinery and equipment, it is necessary to interpolate the exercises in the, modules to form a proper teaching and learning sequence. The sequence of instruction is given in the schedule, of instruction which is incorporated in the Instructor's Guide. With 25 practical hours a week of 5 working days, 100 hours of practical per month is available., The procedure for working through the 48 exercises for the 4th semester with the specific objectives to be achieved, as the learning out comes at the end of each exercise is given in this book., The symbols used in the diagrams comply with the Bureau of Indian Standards (BIS) specifications., This manual on trade Theory forms part of the Written Instructional Material (WIM), which includes manual on trade, practical and assignment/test., , (vi), , Copyright @ NIMI Not to be Republished

Page 7 :

CONTENTS, Lesson No., , Title of the Lesson, , Page No., , Module 1 : Electronic Practice, 4.1.160, , Circuit board soldering and resistor colour coding, , 1, , Soldering technique, , 2, , 4.1.161, , Semiconductor theory/active and passive components, , 10, , 4.1.162, , PN Junction-semiconductor diodes, , 16, , 4.1.163, , Rectifiers, , 21, , 4.1.164, , Transistors, , 29, , 4.1.165, , Transistor biasing and characteristics, , 34, , 4.1.166, , Transistor as a switch, series voltage regulator and amplifiers, , 40, , 4.1.167, , Function generator and cathode ray oscilloscope (CRO), , 47, , 4.1.168, , Printed circuit boards (PCB), , 52, , 4.1.169, , Power electronic devices - UJT and FET, , 55, , 4.1.170, , Power supplies - troubleshooting, , 63, , 4.1.171, , Power control circuit using SCR,DIAC,TRIAC & IGBT, , 69, , 4.1.172, , Integrated circuit voltage regulators, , 77, , 4.1.173, , Binary numbers, logic gates and combinational circuits, , 82, , 4.1.174, , Wave shapes - oscillators and multivibrators, , 88, , Module 2 : Control Panel Wiring, 4.2.175 to 4.2.177, , 4.2.178 & 4.2.179, , Control elements, accessories - layout of control cabinet, , 98, , Power and control circuits for three phase motors, , 106, , Installation of instruments and sensors in control panel and its, performance testing, , 119, , Module 3 : AC/DC Motor Drives, 4.3.180, , AC/DC drives, , 121, , 4.3.181 & 4.3.182, , Speed control of 3 phase induction motor by VVVF/AC drive, , 127, , Module 4 : Inverter and UPS, 4.4.183, , Voltage stabilizer and UPS, , 136, , 4.4.184, , Emergency light, , 144, , 4.4.185, , Battery charger and inverter, , 146, , 4.4.186 & 4.4.187, , Stabiliser, battery charger, emergency light, inverter and UPS, , 151, , 4.4.188, , Installation of inverter in domestic wiring, , 157, , (vii), , Copyright @ NIMI Not to be Republished

Page 8 :

Lesson No., , Title of the Lesson, , Page No., , Module 5 : Power Generation and Substation, 4.5.189, , Sources of energy - Thermal power generation, , 161, , 4.5.190, , Hydel power plants, , 172, , 4.5.191 & 4.5.192, , Visiting of electrical substation, , 176, , Electrical substations, , 177, , Electrical power generation by non conventional methods, , 184, , Tidal power generation, , 188, , Magneto hydro dynamic (MHD) power generation, , 190, , Power generation by solar and wind energy, , 192, , Wind power generation, , 197, , 4.5.193, , 4.5.194 & 4.5.195, , Module 6 : Transmission & Distribution, 4.6.196 to 4.6.198, , Electrical supply system - transmission - line insulators, , 199, , Line insulators, , 203, , Overhead lines /poles erection-fastening of insulator, , 208, , Joining of aluminium conductors, , 216, , 4.6.201, , Domestic service line - IE rules, , 219, , 4.6.202, , Bus-bar system - power tariff terms and definitions, , 222, , Power tariff - terms and definitions, , 225, , 4.6.199 & 4.6.200, , Module 7 : Circuit Breakers and Relays, 4.7.203 & 4.7.204, , Line protective relays - types - operation, , 228, , 4.7.205 & 4.7.206, , Circuit breakers - parts - functions- tripping mechanism, , 233, , Tripping mechanism of circuit breakers, , 239, , Repair and maintenance of CBs, , 241, , 4.7.207, , (viii), , Copyright @ NIMI Not to be Republished

Page 9 :

ASSESSABLE / LEARNING OUTCOME, On completion of this book you shall be able to, • Detect the faults and troubleshoot inverter, stabilizer, battery charger, emergency light and UPS etc., • Plan, assemble and install solar panel, • Erect overhead domestic service line and outline various power, plant layout., • Examine the faults and carryout repairing of circuit breakers., • Identify the control and functional switches in C.R.O and measure, the DC and AC voltage, frequency time period., • Construct and test a half and fullwave rectifiers with and without, filter circuits., • Draw and wire up the control panel for forward/ reverse operation, of induction motor., • Control speed and reverse the direction of rotation of different type, of three phase induction motor using VVVF control /AC drive, , (ix), , Copyright @ NIMI Not to be Republished

Page 10 :

ELECTRICIAN 4TH SEMESTER SYLLABUS, Fourth Semester Duration: Six Month, Week, No., , Learning outcome, Reference, , Professional Skills, (Trade Practical), With Indicative Hours, , Professional Knowledge, (Trade Theory), , 79, , • Assemble simple, electronic circuits, and test for, functioning., , 160. Determine the value of resistance, by colour code and identify types., (10 Hrs), 161. Test active and passive electronic, components and its applications., (15 Hrs), , Resistors - colour code, types and, characteristics., Active and passive components., Atomic structure and semiconductor, theory., , 80-81, , • Assemble simple, electronic circuits, and test for, functioning., , 162. Determine V-I characteristics of, semiconductor diode. (10 Hrs), 163. Construct half wave, full wave and, bridge, rectifiers, using, semiconductor diode. (10 Hrs), 164.Check transistors for their, functioning by identifying its type, and terminals. (10 Hrs), 165. Bias the transistor and determine, its characteristics. (10 Hrs), 166. Use transistor as an electronic, switch and series voltage regulator., (10 Hrs), , P-N, junction,, classification,, specifications,, biasing, and, characteristics of diodes., Rectifier circuit - half wave, full wave,, bridge rectifiers and filters., Principle of operation, types,, characteristics and various configuration, of transistor., Application of transistor as a switch,, voltage regulator and amplifier., , 82-83, , • Assemble simple, Electronic circuits, and test for, functioning., , 167. Operate and set the required, frequency using function generator., (12 Hrs), 168. Make a printed circuit board for, power supply. (10 Hrs), 169. Construct simple circuits containing, UJT for triggering and FET as an, amplifier. (12 Hrs), 170. Troubleshoot defects in simple, power supplies. (16 Hrs), , Basic concept of power electronics, devices., IC voltage regulators, Digital Electronics - Binary numbers,, logic gates and combinational circuits., , 84-85, , • Assemble simple, electronic circuits, and test for, functioning., , 171. Construct power control circuit by, SCR, Diac, Triac and IGBT. (15 Hrs), 172. Construct variable DC stabilized, power supply using IC. (10 Hrs), 173. Practice on various logics by use, of logic gates and circuits. (15 Hrs), 174. Generate and demonstrate wave, shapes for voltage and current of, rectifier, single stage amplifier and, oscillator using CRO. (10 Hrs), , Working principle and uses of, oscilloscope., Construction and working of SCR, DIAC,, TRIAC and IGBT., Principle, types and applications of, various multivibrators., , 86-87, , • Assemble, accessories and, carry out wiring, of control, cabinets and, equipment., , 175. Design layout of control cabinet,, assemble control elements and, wiring accessories for:, (i) Local and remote control of, induction motor. (15 Hrs), (ii) Forward and reverse operation, of induction motor. (10 Hrs), , Study and understand Layout drawing of, control cabinet, power and control, circuits., Various control elements:, Isolators, pushbuttons, switches,, indicators, MCB, fuses, relays, timers, and limit switches etc., , (x), , Copyright @ NIMI Not to be Republished

Page 11 :

ELECTRICIAN 4TH SEMESTER SYLLABUS, Fourth Semester Duration: Six Month, Week, No., , Learning outcome, Reference, , Professional Skills, (Trade Practical), With Indicative Hours, , Professional Knowledge, (Trade Theory), , (iii) Automatic star-delta starter, with change of direction of, rotation. (15 Hrs), (iv) Sequential control of three, motors. (10 Hrs), 88-89, , • Assemble, accessories and, carry out wiring, of control, cabinets and, equipment., , 176. Carry out wiring of control cabinet, as per wiring diagram, bunching of, XLPE cables, channeling, tying, and checking etc. (15 Hrs), 177. Mount various control elements, e.g. circuit breakers, relays,, contactors and timers etc. (10 Hrs), 178. Identify and install required, measuring instruments and, sensors in control panel. (10 Hrs), 179. Test the control panel for its, performance. (15 Hrs), , Wiring accessories: Race ways/ cable, channel, DIN rail, terminal connectors,, thimbles, lugs, ferrules, cable binding, strap, buttons, cable ties, sleeves,, gromats and clips etc., Testing of various control elements and, circuits., , 90-91, , • Perform speed, control of AC, and DC motors, by using solid, state devices., , 180. Perform speed control of DC motor, using thyristors / DC drive. (18 Hrs), 181. Perform speed control and, reversing the direction of rotation, of AC motors by using thyristors /, AC drive. (18 Hrs), 182. Construct and test a universal, motor speed controller using SCR., (14 Hrs), , Working, parameters and applications of, AC / DC drive., Speed control of 3 phase induction motor, by using VVVF/AC Drive., , 92-94, , • Detect the faults, and troubleshoot, inverter, stabilizer,, battery charger,, emergency light, and UPS etc., , 183. Assemble circuits of voltage, stabilizer and UPS. (15Hrs), 184. Prepare an emergency light., (10 Hrs), 185. Assemble circuits of battery, charger and inverter. (15 Hrs), 186. Test, analyze defects and repair, voltage stabilizer, emergency light, and UPS. (15 Hrs), 187. Maintain, service and troubleshoot, battery charger and inverter., (10 Hrs), 188. Install an Inverter with battery and, connect it in domestic wiring for, operation. (10 Hrs), , Basic concept, block diagram and, working of voltage stabilizer, battery, charger, emergency light, inverter and, UPS., Preventive and breakdown maintenance., , 95, , • Erect overhead, domestic service, line and outline, various power, plant layout., , 189. Draw layout of thermal power plant, and identify function of different, layout elements. (5 Hrs), 190. Draw layout of hydel power plant, and identify functions of different, layout elements. (5 Hrs), , Conventional and nonconventional, sources of energy and their comparison., Power generation by thermal and hydel, power plants., , (xi), , Copyright @ NIMI Not to be Republished

Page 12 :

ELECTRICIAN 4TH SEMESTER SYLLABUS, Fourth Semester Duration: Six Month, Week, No., , Learning outcome, Reference, , Professional Skills, (Trade Practical), With Indicative Hours, , Professional Knowledge, (Trade Theory), , 191. Visit to transmission / distribution, substation. (10 Hrs), 192. Draw actual circuit diagram of, substation visited and indicate, various components. (5 Hrs), 96, , • Plan, assemble, and install solar, panel., • Erect overhead, domestic service, line and outline, various power, plant layout., , 193. Prepare layout plan and Identify, different elements of solar power, system. (05 Hrs), 194. Prepare layout plan and Identify, different elements of wind power, system. (05 Hrs), 195. Assemble and connect solar panel, for illumination. (15 Hrs), , 97, , • Erect overhead, domestic service, line and outline, various power, plant layout., , 196. Practice installation of insulators Transmission and distribution networks., used in HT/LT line for a given Line insulators, overhead poles and, voltage range. (5 hrs), method of joining aluminum conductors., 197. Draw single line diagram of, transmission and distribution, system. (5 Hrs), 198. Measure current carrying capacity, of conductor for given power, supply. (5 hrs), 199. Fasten jumper in pin, shackle and, suspension type insulators., (10 Hrs), , 98, , • Erect overhead, domestic service, line and outline, various power, plant layout., , 200. Erect an overhead service line pole, for single phase 230 V distribution, system in open space. (10 Hrs), 201. Practice on laying of domestic, service line. (10 Hrs), 202. Install bus bar and bus coupler on, LT line. (5 Hrs), , Safety precautions and IE rules, pertaining to domestic service, connections., Various substations., Various terms like - maximum demand,, average demand, load factor, diversity, factor, plant utility factor etc., , 99, , • Examine the faults, and carry out, repairing of, circuit breakers., , 203. Identify various parts of relay and, ascertain the operation. (5 Hrs), 204. Practice setting of pick up current, and time setting multiplier for relay, operation. (5 hrs), 205. Identify the parts of circuit breaker,, check its operation. (5Hrs), 206. Test tripping characteristic of circuit, breaker for over current and short, circuit current. (5 hrs), 207. Practice on repair and, maintenance of circuit breaker., (5 hrs), , Types of relays and its operation., Types of circuit breakers, their, applications and functioning., Production of arc and quenching., , (xii), , Various ways of electrical power, generation by non-conventional methods., Power generation by solar and wind, energy., Principle and operation of solar panel., , Copyright @ NIMI Not to be Republished

Page 13 :

ELECTRICIAN 4TH SEMESTER SYLLABUS, Fourth Semester Duration: Six Month, Week, No., , Learning outcome, Reference, , Professional Skills, (Trade Practical), With Indicative Hours, , Professional Knowledge, (Trade Theory), , 100-101 Project work / Industrial visit, Broad Areas:, a) Battery charger/Emergency light, b) Control of motor pump with tank level, c) DC voltage converter using SCRs, d) Logic control circuits using relays, e) Alarm/indicator circuits using sensors, 102-103, , Revision, , 104, , Examination, , (xiii), , Copyright @ NIMI Not to be Republished

Page 14 :

Copyright @ NIMI Not to be Republished

Page 15 :

Electrical, Electrician - Electronic Practice, , Related Theory for Exercise 4.1.160, , Circuit board soldering and resistor colour coding, Objectives: At the end of this lesson you shall be able to, • distinguish between eyelet board, lug board and PCB, • explain the preparation of components for mounting and method of soldering on boards, • explain the inspection of solder joints and defects in soldered joints, • explain construction, types, function, colour coding and application of resistors in circuits., In assembling of electronic circuits using components, it, is required to layout (arrange), mount and wire the, components in a systematic manner. In wiring the electronic, circuits depending upon the circuit, different types of, boards are used., , The required circuit pattern on the laminated board is, made by process called “etching”. Etching is the process, of removing the portion of the metal foil, leaving behind only, the required portion refer Fig 3., , Type of boards, 1 Eyelet board, 2 Lug or tag board, 3 Printed Circuit Boards (PCB’s), Eyelet Board (Fig 1) : In this, eyelets are riveted on, perforated bakelite boards. Refer Fig 1. In this type of, board, eyelets can be riveted only to a limited number,, depending on the lay-out of the circuits., , Lug or tag board (Fig 2) : In this type of boards, brass, lugs are riveted in rows on insulated board like bakelite. In, this type, components are to be arranged, and circuits are, to be made without altering the lug position., , For general purpose, printed circuit boards are readily, available to design and develop electronic circuits. They, are also called as matrix boards. A strip type matrix board, is shown in Fig 4., , Securing and fixing of components: Mounting of, components on eyelet board / lug board / tag board or PCB, involves 4 main activities, namely,, 1 Preparation of component leads and surfaces to be, soldered., 2 Shaping the components leads., 3 Bending and trimming the excess length before, soldering., 4 The order of mounting and soldering., , PCB (Printed circuit board) : A printed circuit board in, which inter connecting wires are replaced by a thin, conducting surface called copper on silver foil which is, moulded in one side of the insulated board. The insulating, board is generally made up of phenolic (or) paper or fibre, glass or epoxy., , 1 Preparation of components leads and surfaces, etc.: Dust, oil, oxide layer paint or any protective, coating on the component leads and surfaces must be, removed at places where soldering has to be done., 2 Shaping the components: The shape to which the, components leads are to be bent depends up on the, manner in which the component is to be mounted., Care should be taken to reduce the thrust on the, component., , Copyright @ NIMI Not to be Republished, , 1

Page 16 :

Depending on the type of component lead, and the space, available on the PCB, component can be mounted either, vertically (or) horizontally as in Fig 5., , 3 Bending and trimming : Once the components leads, are inserted into the holes of PCB, lead length in excess, (0.5 mm to 3 mm), from the PCB surface should be, trimmed, using side cutting pliers as in Fig 6., , After cutting the excess lead length, the component lead, must be bend and terminated, on PCB., 4 Order of mounting: Mount the components in the, order as per layout, and should be easy to trace the, circuit, as per connection diagram., The technique used for soldering is explained in subsequent, lesson., , Soldering technique, Objectives : At the end of this lesson you shall be able to, • list the critical factors and stages in soldering, • list the steps involved in selecting and preparing the materials, • list the different shapes of tips and inspection of soldering iron, • state the functions of soldering iron stand and inspection of soldering iron, • state the technique of soldering electronic components and effect of residual flux, • state the defects in soldering joints., Soldering, Soldering is the process of joining two metals for a, permanent joint/connections. The bonding of two metals, done by using alloy of two metals-lead and tin called solder, in different ratios to solder electronic component like, resistors, capacitor, transistor etc., Soldering a joint: Selection and preparation of the, soldering materials and cleaning the surfaces to be, soldered are the most time consuming phase of making a, solder joint. Heating the joint and applying solder is the, least time consuming but, all these steps contribute, heavily for the good soldered joint., Critical factor during soldering, 1 Controlling the temperature of the workpiece., 2 Limiting the time that a workpiece is to be held at, soldering temperature., These factors are specially critical while soldering, electronic components like resistors, capacitors,, transistors, ICs etc., Failure of correct, time and, coordinate the heating of the joint and add solder, will, result in a poor quality joint and may even damage the, components., 2, , Stage in soldering: The soldering process can be divided, into several distinct stage or phases as given below:, 1 Selection and preparation of materials, 2 Cleaning the surfaces to be soldered, 3 Heating the joint and adding solder, 4 Cooling the joint, 5 Cleaning the joint, 6 Inspecting the joint., 1 Selection and preparation of materials, Selection of soldering iron wattage : Soldering irons, are available in different wattage ratings starting from 10, watts to several 100 watts. The wattage of a soldering iron, specifies the amount of heat it can produce. As a thumb, rule, higher the physical dimension of the workpiece,, higher should be the wattage rating of the soldering iron., Some of the suggested wattage of soldering iron are given, below:, i) For soldering, less temperature sensitive component, such as, resistors on lug boards or tag boards, use 25, to 60W iron. For soldering on printed circuit boards,, use 10 to 25 W iron., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.160, , Copyright @ NIMI Not to be Republished

Page 17 :

ii) For soldering highly temperature sensitive components, such as, diodes, transistors and integrated circuits,, use 10 to 25 watts iron., Selection of soldering iron tip: To ensure that the joint, is heated to the required temperature ideally,, – the area of the tip face should be approximately equal, to the area of the joint to be soldered, – the tip should be long enough to allow easy access to, the joint., -, , the tip should not be too long, as this may result in the, low temperature at the tips working face., , In most soldering irons, the tip can be easily removed and, can be replaced., Selection of tip shape: Suggested soldering tip shapes, and their application are given below;, Type of soldering tip shape, , Application, , Wires, resistor and, the passive components, on lug boards, , CHISEL TIP, , All miniature electronic, components except ICs on, to lug boards and printed, circuit boards (PCB), , BEVEL TIP, , Integrated circuits (ICs), on to printed circuit boards, (PCBs), , CONICAL TIP, , Selection of solder and flux: For electronic soldering, applications, solder of tin and lead of 60/40 proportion is, used. This solder proportion has a melting point of 200°C, which is the required temperature for general purpose, soldering irons., For electrical purpose, resin core solders are used., For ease of application, the flux used in addition to the, cored flux in solder, should be in paste form., Flux is a chemical substance which has acidic properties., Therefore, it is advised not to touch the flux by hand. Use, a stick or a thin stiff brush to apply flux on the work pieces., Hands should be washed after soldering work., , Inspection of soldering iron: Most soldering irons are, powered by AC main voltage. This voltage level is high and, can give shock if one is careless. Soldering irons will, generally have lengthy mains cable. While using the iron,, the mains cable gets twisted and will have to bear physical, stain. Because of this strain, the insulation of cable may, get cut. This may lead to live wires protruding out. The live, wires give severe electrical shocks if it touches the user., Hence, a thorough inspection of the soldering iron cable is, a must before using it., Preparation of soldering iron for soldering: The, soldering bit tip should be cleaned, heated and tinned, before starting the soldering work., Cleaning the surfaces to be soldered: Before joining, two pieces of metal by soldering, the joining surfaces, should be cleaned to remove foreign matters over the, surface. Also the jointing surfaces should be free from, grease grit or oil. this could be achieved by using either, a knife or by a sand paper and cloth., 2 Heating the joint and adding solder: Tips for, heating and applying solder to a joint to be soldered are, given below:, – Do not apply too much flux on a joint in one place., Apply a small amount of flux around the joint. Do not, allow the flux to flow outside the area to be soldered., – Place the iron tip at the joint such that the tip gets, maximum contact with parts to be joined as in Fig 2, , Soldering stand: Soldering stand plays an important role, of retaining the soldering iron tip temperature around the, required soldering temperature. The soldering stand should, not allow the external temperature to cool the bit. At the, same time the stand should not contain all the heat, generated., Soldering stands are specially designed as in, Fig 1 to fulfill the above requirements. Such a design also, prevents accidental burn injuries to the user of the soldering, iron and the stand remains stable mechanically., Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.160, , Copyright @ NIMI Not to be Republished, , 3

Page 18 :

Slowly feed the solder into the joint starting close to the, soldering tip and moving towards the edge of the joint as, in Fig 3, , Continue applying the solder to the joint until complete, wetting of the joint has been achieved and the joint has a, concave fillet as in Fig 4, , After enough solder has been applied and solder wire, removed, keep the soldering iron tip on the joint for a, moment to ensure that all the flux on the joint has reached, the soldering temperature. This will allow majority of the, acids within the joint to break down, which otherwise will, corrode the joint after a period of time., Generally the time taken to make a good soldered joint is, between 3 to 7 seconds from applying the soldering iron, to and removing the soldering iron., 3 Cooling the joint: Tips for cooling a solder joint are, given below:, – Allow the joint to cool without assistance, do not blow, air from your mouth or from any other source to cool the, joint. Forced cooling, cools the joint much earlier than, it has to, resulting in a dry and brittle solder joint which, will lead to mechanical and electrical defects of the, joint., – Do not move any part of the joint while it is cooling. This, disturbs the chemical bonding taking place. Movement, of the joint while it is cooling results in a dry joint., 4 Cleaning the joint : When a solder joint is made, the, amount of flux applied should be just sufficient to make, a good joint. But, quite often, there will be a brown, waxy substance left on the joint. This is nothing but the, flux residue. In its original state this residue is corrosive., Hence, the flux residue or excess flux must be removed, from the joint before soldering can be considered as, complete., If the flux residue and excess flux are not properly, removed, their corrosive nature of the flux will gradually, destroy the component leads and the circuit board. The, flux residue is also sticky and, if not removed, will collect, dust and debris leading to circuit failure., 4, , Removal of flux residue requires the use of solvents. The, type of solvent depends on the flux used., Iso Propyl Alcohol (IPA) is one of the solvents used for, removing residual flux. It is available either undiluted or, pre-mixed with water and can be obtained in pump sprays,, aerosols, cans and drums depending on the quantity and, style of use., Cleaning using water/IPA solution: Determine the, right method of application. (spray or liquid). Apply the, solvent to the soldered joint. Use a clean brush, or some, other type of stiff brush, to gently scrub the joint as in, Fig 5, to help dissolve the residue, taking care to avoid, splashing the mixture., , When the residue has been dissolved, dry the joint with a, lint-free cloth to remove as much of the dissolved residue, as possible., Inspection of soldered joints: Soon after making a, solder joint, as a quick check, the following features of the, solder joint should be checked:, 1 Soldered joint must be bright and shiny., 2 Soldered joint must be smooth and symmetrical., Surface colour - The surface of a correctly soldered joint, will be glossy, silvery and uniform in colour., Surface texture - The surface texture of a correctly, soldered joint will be smooth, even and non-grainy. There, shall be no signs of pitting on the surface of the solder., Common soldering defects: Defects in solder joints can, be grouped as follows:, 1 Temperature defects, 2 Wetting defects, 3 Solder quantity defects, 4 Mechanical defects., Temperature defects: Temperature defects are caused, by excessive or insufficient heating of the joint during the, soldering process., Defects due to excessive heating: The solder on an, overheated joint will have grainy tenure, dull grey colour, and pitted., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.160, , Copyright @ NIMI Not to be Republished

Page 19 :

Too much heat can lead to one or more of the following, defects:, – Overheating of the resin flux, causes the flux to char, and lose its ability to remove oxides. Lumps of charred, flux gets trapped in the solder forming pits and voids., – Overheating of the solder, causes excessive alloying, between the copper parts of the connection and the tin, content of the solder. This in turn causes localized, depletion of the tin and results in a brittle joint., – Excessive oxidisation of the solder. The oxidised, solder forms a poor bond with the other parts of the, joint., , Wetting defects are easily recognised by the inability of, the solder to cover all the metal surfaces at the joint and, the formation of a large dihedral angles as in Fig 6., , Defects due to insufficient heating: Too little heat can, lead to one or more of the following defects:, , On severely tarnished surfaces, the solder will not flow, over the tarnished surface(non-wetting) or the solder, initially flows over the tarnished surface, but then retreats, leaving small globules of solder on the surface (de-wetting), as in Fig 6., , A defect known as a cold joint. A cold joint occurs when, the flux is unable to remove the tarnish from the joint. At, low soldering temperature the flux is only partly activated., Therefore, it is less effective in removing tarnish., Insufficiently heated solder joint results in,, – poor wetting of the joint, – a course solder fillet, , Solder quantity defects(Refer Fig 7 and 8): Solder, quantity defects are due to either too little or too much, solder applied to a connection., Too little solder results in a small size of the solder fillet as, in Fig 7. The small solder fillets makes a joint weak., , – solder steps at the edges, The effects of a cold joint are,, – high electrical resistance, – low mechanical strength, – dry solder joint, A defect known as a dry joint occurs when the solder is too, viscous to push the flux away from the component lead., A layer of the flux becomes trapped around the lead. This, layer of flux causes a weak bond and hence a poor, electrical connection., Causes of incorrect soldering temperatures, A common indicator of incorrect soldering temperature is, the formation of small peaks at the tip of the joint as the, iron is pulled away. These peaks will be formed at either, too high or too low soldering temperature., , Too much solder results in convex solder fillets as in, Fig 8. This defect is recognised by the large size and the, convex shape of the fillets., , Incorrect soldering temperature may be due to,, – incorrect wattage of the soldering iron, – incorrect soldering tip selection, – insufficient heating of the soldering iron, – poor soldering technique, leading to poor heat transfer, from the tip of the iron to the joint., Wetting defects (Refer Fig 6), The degree of wetting of a joint depends greatly on the, cleanliness of the parts to be joined., , Mechanical defects: Mechanical defects of a solder joint, are caused by;, – the movement of parts of a joint while the solder is, cooling., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.160, , Copyright @ NIMI Not to be Republished, , 5

Page 20 :

Movement during cooling causes severe dislocation of the, crystalline structure of the solder. This results in a weak, joint which may fracture later and cause high electrical, resistance or an intermittent fault when the circuit is in, use. A joint moved before cooling will have a frosted, appearance with fractures., , One type of Wire-wound resistor is called as fusible, resistor enclosed in a porcelain case. The resistance is, designed to open the circuit when the current through it, exceeds certain limit., , – stresses imposed on the joint as it cools., , These are made of fine carbon or graphite mixed with, powdered insulating material as a binder in the proportion, needed for the desired resistance value. Carbon-resistance, elements are fixed with metal caps with leads of tinned, copper wire for soldering the connection into a circuit., Fig 10 shows the construction of carbon composition, resistor., , Stresses on the joint are usually as a result of inadequate, stress relief bends in the leads of components. A, stressed joint usually breaks due to the expansion and, contraction of components while in use, due to temperature, variations., , 2 Carbon composition resistors, , Blowing on the soldered joint to attempt to speed up, cooling will introduce several additional cooling stresses., Connections that have been disturbed as they cool usually, have a frosted appearance., Never forget the rule, if the quality or reliability of the joint, is in doubt, de-solder the joint and re-solder it fresh., Resistors: These are the most common passive component, used in electronic circuits. A resistor is manufactured with, a specific value of ohms (resistance). The purpose of, using a resistor in circuit is either to limit the current to a, specific value or to provide a desired voltage drop (IR). The, power rating of resistors may be from 0.1 W. to hundreds, of Watts., , Carbon resistor are available in values of 1 ohm to 22, megohms and of different power ratings, generally 0.1,, 0.125, 0.25, 0.5 and 2 watts., 3 Metal film resistors ( Fig 11), , There are four types of resistors, 1 Wire-wound resistors, 2 Carbon composition resistors, 3 Metal film resistors, 4 Carbon film resistors, 1 Wire-wound resistors, Wire-wound resistors are manufactured by using resistance, wire (nickel-chrome alloy called Nichrome) wrapped around, an insulating core, such as ceramic porcelain, bakelite, pressed paper etc.Fig 9, shows this type of resistor.The, bare wire used in the unit is generally enclosed in insulating, material. Wire wound resistors are used for high current, application. They are available in wattage ratings from one, watt to 100 watts or more. The resistance can be less than, 1 ohm and go up to several thousand ohms. They are also, used where accurate resistance values are required., , Metal film resistors are manufactured by two processes., Thick film resistors are pasted with metal compound and, powdered glass which are spread on the ceramic base and, then backed., Thin film resistors are processed by depositing a metal, vapour on a ceramic base. Metal film resistors are, available from 1 ohm to 10 MΩ, upto 1W. Metal film, resistors can work from 120°C to 175°C., 4 Carbon film resistors (Fig 12), , In this type, a thin layer of carbon film is deposited on the, ceramic base/tube. A spiral groove is cut over the surface, to increase the length of the foil by a specialised process., , 6, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.160, , Copyright @ NIMI Not to be Republished

Page 21 :

Carbon film resistors are available from 1 ohm to few, Meg ohm and up to 2W and can work from 85°C to 155°C., All the above four types of resistors are coated with, synthetic resin to protect them against mechanical, damages and climatic influences, It is therefore, difficult to, distinguish them from each other externally., , It is provided with 3 terminals as shown in Fig 13 and 14., They are available with carbon tracks (Fig 13) and wire, wound (Fig 14) types. Trimmer potentiometers (or), resistor which can be adjusted with the help of a small, screw driver. (Fig 15)., , Specification of resistors: Resistors are specified, normally with the four important parameters, 1 Type of resistor, 2 Nominal value of the resistors in ohm (or) kilo ohm (or), mega ohm., 3 Tolerance limit for the resistance value in percentage., 4 Loading capacity of the components in wattage, Example, 100 ± 10% , 1W, where as nominal value of resistance is, 100Ω., The actual value of resistance may be between 90 Ω to, 110 Ω, and the loading capacity is maximum 1 watt., The resistors can also be classified with respect to their, function as, 1 Fixed resistors, 2 Variable resistors, Fixed resistors : The fixed resistors is one in which the, nominal value of resistance is fixed. These resistors are, provided with pair of leads. (Fig 10 to 12), Variable resistors (Fig 13) : Variable resistors are those, whose values can be changed. Variable resistors includes, those components in which the resistance value can be, set at the different levels with the help of sliding contacts., These are known as potentiometer resistors or simply as, a potentiometers., , Resistance depends upon temperature, voltage,, light: Special resistors are also produced whose resistance, varies with temperature, voltage, and light., PTC resistors (Sensistors) : Since, different materials, have different crystal structure, the rate at which resistance, increases with raising temperature varies from material to, material. In PTC resistor (positive temperature coefficient, resistor), as the temperature increases, the resistance, increases non linearly. For example, the resistance of, PTC at room temperature may be of nominal value 100 Ω, when the temperature rises say 10°C, it may increase to, 150 Ω and with further increase of another 10°C, it may, increases to 500 Ω., NTC Resistors (Thermistors) : In case of NTC resistors, (Negative temperature co-efficient resistors) as the, temperature increases, the value of resistance decreases, non-linearly, For example, NTC resistor, which has nominal, value of resistance is 500 Ω at room temperature may, decrease to 400 Ω with the rise of 10°C temperature and, further decrease to 150 Ω when the temperature rises to, another 10°C., The PTC and NTC resistors can perform switching operation, at specific temperature. They are also used for, measurements and temperature compensators., VDR (Varistors) : The VDR (Voltage dependent resistor), resistance falls non-linearly with increasing voltage. For, example, a VDR, may have 100 Ω resistance at 10 V, and, it may decrease to 90 Ω at rise in 5V. By further increasing, the voltage to another 5V, the resistance may fall to 50 Ω., The VDRS are used in voltage stabilisation, arc quenching, and over voltage protection., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.160, , Copyright @ NIMI Not to be Republished, , 7

Page 22 :

Light dependent resistor (LDR): The LDRs are also, known as photo- conductors. In LDRs the resistance falls, with increase in intensity of illumination. The phenomena, is explained as the light energy frees some electron in the, materials of the resistors, which are then available as extra, conducting electrons. The LDR shall have exposed surface, to sense the light. These are used for light barriers in, operating relays. These are also used for measuring the, intensity of light., Marking codes for resistors, Commercially, the value of resistance and tolerance value, are marked over the resistors by colour codes (or) letter, and digital codes., Resistance and tolerance value of colour coded, resistors., The colour codes for indicating the values to two significant, figure and tolerances are given in Table 1 as per IS:8186., Table 1, Values to two significant, figures and tolerances, corresponding to colours, Colour, , First, Band/, Dot, , Second, Band/, Dot, , Third, Band/, Dot, , Fourth, Band/, Dot, , First, Figure, , Second Multiplier Tolerance, Figure, , Example, Resistance value : If the colour band on a resistor are in, the order- Red, Violet, Orange and Gold, then the value of, the resistor is 27,000 ohms with +5% tolerance., First, colour, , Second, colour, , Third, colour, , Fourth, colour, , Red, , Violet, , Orange, , 2, , 7, , 1000(10 ), , Gold, 3, , ±5%, , Tolerance value: The fourth band (tolerance) indicates, the resistance range within which is the actual value falls., In the above example, the tolerance is ±5%. ±5% of 27000, is 1350 ohms. Therefore, the value of the resistor is any, value between 25650 ohms and 28350 ohms. The, resistors with lower value of tolerance (precision) are, costlier than normal value of resistors., , Silver, , —, , —, , 10, , ± 10 %, , For less than ten ohms, the third band will be either golden, or silver., , Gold, , —, , —, , 10, , ±5%, , The colours are,, , Black, , —, , 0, , 1, , —-, , Gold -, , 10-1, , =, , 1/10 = 0.1, , Brown, , 1, , 1, , 10, , ±1%, , Silver -, , 10-2, , =, , 1/100 = 0.01, , Red, , 2, , 2, , 102, , ±2%, , Orange, , 3, , 3, , 103, , —-, , Yellow, , 4, , 4, , 104, , Green, , 5, , 5, , Blue, , 6, , Violet, , -2, -1, , Example (Refer Fig 17), , —-, , Colour of, Ist Band, Orange, , Colour of, 2nd Band, White, , Colour of, 3rd Band, Gold, , 105, , —-, , 3, , 9, , 1/10, , 6, , 10, , —-, , 7, , 7, , 7, , 10, , —-, , Grey, , 8, , 8, , 108, , —-, , White, , 9, , 9, , 10, , —-, , None, , —, , —, , —, , ± 20 %, , 6, , 9, , The two significant figures and tolerances colour coded, resistors have 4 bands of colours coated on the body as, in Fig 16., The first band shall be the one nearest to one end of the, component resistor.The second, third and four colourbands, are shown in Fig 16., 8, , The first two colour bands indicate the first two digits in the, numeric value of resistance. The third colour band, indicates the multiplier.The first two digits are multiplied, by the multiplier to obtain the actual resistance value. The, forth colour band indicates the tolerance in percentage., , thus, the value of resistor is 39/10 or 3.9 ohms., , Large value resistances are expressed in kilo ohms and, megohms. Letter 'k' stands for kilo and M stands for, mega. One kilo equals 1000 (103) and one mega equals, 1000000 (106). The resistance values are expressed as, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.160, , Copyright @ NIMI Not to be Republished

Page 23 :

1000 ohms, , =, , 1k, , 1800 ohms, , =, , 1k 8, , 100 ohms, , =, , 0.1 k, , 10000 ohms, , =, , 0.1 M, , 1500000 ohms, , =, , 1 M 5., , Preferred values for resistors: It is not possible to, manufacture all values of resistors right from one ohm to, a million ohms. So only a set of preferred values of, resistors are generally made. Also in the manufacturing, process, in which thousands of resistors are made in a, day, it is not possible to adjust every ordinary resistor to, an exact value. The term ‘tolerance’ denotes the acceptable, deviation in the resistance value of a resistor.The usual, specified tolerances are ±5%, ±10% and ±20% for the, ordinary resistors. The precision resistors may have, selected tolerances as close as ±0.1%. In each tolerance, range, a set of preferred values are available refer Table 2., Table 2, , E12 Series, Tolerance, ± 10 percent, , E 24 Series, Tolerance, ±5 percent, , E12 Series, Tolerance, ± 10 percent, , E 6 Series, Tolerance, ±20 percent, , 5.6, , 5.6, , —, , 6.2, , —, , —, , 6.8, , 6.8, , 6.8, , 7.5, , —, , —, , 8.2, , 8.2, , —, , 9.1, , —, , —, , Letter and digit code for resistance values: In this, system of coding, numbers and letter are used. Generally, three or four, or five characters consisting of, 1 Two figures and letters, 2 Three figures and letter,, 3 Four figures and letters are used as the case may be., , Preferred series of values for resistors, with ordinary tolerances, E 24 Series, Tolerance, ±5 percent, , Table 2 contd., , E 6 Series, Tolerance, ±20 percent, , 1.0, , 1.0, , 1.0, , 1.1, , —, , —, , 1.2, , 1.2, , —, , 1.3, , —, , —, , 1.5, , 1.5, , 1.5, , 1.6, , —, , —, , 1.8, , 1.8, , —, , 2.0, , —, , —, , 2.2, , 2.2, , 2.2, , 2.4, , —, , —, , 2.7, , 2.7, , —, , 3.0, , —, , —, , 3.3, , 3.3, , 3.3, , 3.6, , —, , —, , 3.9, , 3.9, , —, , 4.3, , —, , —, , 4.7, , 4.7, , 4.7, , 5.1, , —, , —, , The letter R.K. and M. shall be used for multipliers of the, resistance values expressed in ohms R = (10°) = 1, k =103, = 1000, M = 10 6 = 1 000000, For example (Fig 18), 0.1Ω is coded as R10 and 1200 Ω or 1.2k Ω is coded as, 1.2 kΩ similarly 1500000 Ω or 1.5 M Ω is coded as, 1 M 5., For symmetrical tolerance in percentage the following, letter shall be used for indicating tolerance of the resistance, ±5% = J, ±10% = K, ±20% = M, For example (Refer Fig 18), 1 1.5 Ω ±10% 1 W is letter coded as K 1R51W, 2 330 Ω ±20% 0.5 W is letter coded as M 330R 0.5W, 3 2.7 K Ω ±5% 2W is letter coded as J 2K72W, 4 1M Ω ±20% 1 W is letter coded as M 1M1W, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.160, , Copyright @ NIMI Not to be Republished, , 9

Page 24 :

Electrical, Electrician - Electronic Practice, , Related Theory for Exercise 4.1.161, , Semiconductor theory-Active and passive components, Objectives: At the end of this lesson you shall be able to, • explain atom conductor, semiconductor, insulator and atomic structure, • state the function of N and P type semiconductor, PN junction, depletion region, • state the coding of semiconductor devices and its meaning, • explain active and passive components, symbols - uses., Atom, The very tiny fundamental unit of an element which is, capable of independent existence is the atom. An atom, of any element consists of a central core called Nucleus., A number of small particles called electrons move around, the central core., The nucleus contains protons and neutrons. A proton in, the nucleus possess a positive electrical charge. An, electron in an atom possess negative electrical charge. In, normal state, the atom is electrically neutral, that is the, number of electrons is equal to the number of protons in, the nucleus., , themselves in different orbits. There are 2 electrons in the, first orbit, 8 electrons in the second orbit, and 18 electrons, in the third orbit. The fourth orbit is the outer or valence orbit, which contains 4 electrons., Fig 1b shows a silicon atom. It has 14 protons in the, nucleus and 14 electrons in 3 orbits. There are 2 electrons, in the first orbit and 8 in the second orbit. The remaining, 4 electrons are in the outer or valence orbit., , For stability of materials (solids), the valence (outer most), shell of an atom should contain either 8 or more number, of electrons, if it is to be complete.The above stability, keeps the atoms and the molecules together in a solid, state., There are three important kinds of bonding amongst the, atoms and the molecules of a solid. They are i) ionic ii), covalent and iii) metallic bonds., Examples of solids under different bondings are,, lonic bond, , :, , sodium chloride, , Covalent bond, , :, , silicon and germanium, , Metallic bond, , :, , metals like copper, , Difference between conductors insulators and semi, conductors: We are familiar with conducting and insulating, materials. Conducting materials are good conductors of, electricity. Insulating materials are bad conductors of, electricity. There is another group of materials called as, semiconductors, such as germanium and silicon. These, are neither good conductors nor good insulators., , In semiconductor materials, the atoms are arranged in an, orderly pattern called a crystal lattice structure. If a pure, silicon crystal is examined we find that the four electrons, in the outer (valence) shell of an atom is shared by the, neighbouring atoms as in Fig 2., , The conductors on valence electrons are always free. In, an insulator the valence electrons are always bound., Whereas in semi conductors the valence electrons are, normally bound but can be set free by supplying a small, amount of energy. Several electronic devices are made, using semi conductor materials., Semi conductors - Atomic structure: Germanium (Ge), and silicon (Si) are examples of semi conductors. Fig 1a, shows a germanium atom. In the centre is a nucleus with, 32 protons. 32 revolving electrons are distributed, 10, , Copyright @ NIMI Not to be Republished

Page 25 :

The union of atoms sharing the valence electrons is called, a covalent band.That means a valence electron being, shared by two adjacent atoms. Each atom appears to, have a full outer shell of eight electrons., Types of semiconductors : A pure semiconductor is, called an intrinsic semiconductor. For example, a silicon, crystal is an intrinsic semiconductor because every atom, in the crystal is a silicon atom. One way to increase, conductivity in a semiconductor is by ‘doping’. This, means adding impurity atoms to an intrinsic semiconductor., The doped semi-conductor is known as an extrinsic, semiconductor., , electron. The number of such free electrons is controlled, by the amount of arsenic added to the crystals., In N-type, the free electrons are called the majority, carriers, and the holes minority carriers., P-type semiconductor : To obtain more holes, a pure, silicon crystal is doped with elements such as aluminum, or boron or gallium. The atoms of each of these elements, have three electrons only in their outer orbit. Adding, gallium to pure silicon crystals allows the atoms of the two, elements to share seven electrons. (Fig 5), , The residual heat at room temperature (300K) is sufficient, to make a valence electron of an intrinsic semiconductor, to move away from the covalent bond and then the covalent, bond is broken, and the electron becomes a free electron, to move in the crystal. This is shown in Fig 3., , A hole is created in the place of the eighth electron. Now, that the number of holes exceeds the number of free, electrons the substance becomes ‘P’ type material. The, holes in P-type are the majority carriers, and the free, electrons are the minority carriers., PN Junction : A PN junction is formed by combining P, and N type materials. The surface where they meet is, called the PN junction. A PN junction is illustrated in, Fig 6., , When an electron breaks a covalent bond and moves, away, a vacancy is created in the broken covalent bond., This vacancy is called a ‘hole’. A hole has a positive, charge. When a free electron is liberated, a hole is, created., N - type semiconductor : A semiconductor with excess, of electrons is called N-type. To obtain excess free, electrons the element doped with the semiconductor, material is arsenic, or antimony or phosphorus. Each of, these atoms has five electrons in its outer orbit. (Fig 4), The free electrons in the N-regions diffuse across the, junctions into the P-region. The free electrons lose energy, and recombine with the holes in the P-regions.This, recombination eliminates a free electron and a hole., When the electron moved from the N-region and diffused, across the junction, it leaves the atom to be a positive ion., , Because the outer orbits of the atoms can hold eight, electrons, no hole is available for the fifth electron in the, arsenic atoms to move into. It, therefore, becomes a free, , The positive ion is not balanced by a negative charge in the, N-region. The hole is eliminated in the P-region by, recombination. The elimination of the hole and its positive, charge leaves the atom to be a negative ion in the P-region., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.161, , Copyright @ NIMI Not to be Republished, , 11

Page 26 :

The ions in the crystal structure are fixed and cannot, move. Thus, a layer of fixed charges is formed on the two, sides of the junctions. This is shown in Fig 7., , A, , – diode or rectifier, , AP – photo-diode, AZ, , – voltage regulator diode, , C, , – transistor, , CP – phototransistor, The group of figures in a serial number indicating a, particular design or development., Present system : This system consists of two letters, followed by a serial number. The serial number may, consists of three figures of one letter and two figures, depending on the main application of the device., The first letter indicates the semiconductor material used., A Germanium, There is a layer of positively charged ions on the N-side, and on the P-side of the junction there is a layer of, negatively charged ions. An electric field is created across, the junction between the oppositely charged ions. This is, called a junction field. The junction field is also known as, ‘barrier’. The distance between the sides of the barrier is, the ‘width’ of the barrier., Depletion region : The carrier in the vicinity of the, junction are involved in forming the junction. Once the, junction field is established, no carriers can move through, the junction. Hence the junction field is called ‘depletion, region’ or ‘space charge region’. This layer is called the, depletion layer, because there are neither free electrons, nor holes present. This depletion region prevents further, movement of electrons from the N-material to the, P-material and thus an equilibrium is reached., The intensity of the field is known as ‘barrier height’ or, ‘potential’ hill’. The internal voltage set up due to positive, and negative ions at the junction is called barrier potential., If any more electrons have to go over from the N-side to, P-side, they have to over come this barrier potential. This, means, only when the electrons on the N-side are supplied, with energy to overcome the barrier potential they can go, over to the P-side., In order to cancel the barrier potential and the electrons, to cross over a potential difference of 0.7 V is required for, a silicon diode and 0.3 V for a germanium diode. The, barrier voltage is more for silicon because its lower atomic, number allows more stability in the covalent bonds. The, barrier potential decreases at higher temperatures., Old system : Some earlier semiconductor diodes and, transistors have type numbers, consisting of two or three, letters followed by group of one, two or three figures. The, first letter is always ‘O’, indicating a semi-conductor, device., , B Silicon, C Compound materials such as gallium arsenide, R Compound materials such as cadmium sulphide, The second letter indicates the general function of the, device., A detection diode, high speed diode, mixer diode, B variable capacitance diode, C transistor for I.F. applications (not power types), D power transistor for A.F. applications (not power types), E tunnel diode, F transistor for A.F. applications (not power types), G multiple of dissimilar devices, miscellaneous devices, L power transistor for a.f. applications, N photo-coupler, P radiation sensitive device such as photo-diode, phototransistor, photo-conducive cell, or radiation detector, diode, Q radiation generating device such as light-emitting diode, R controlling and switching devices (e.g. thyristor) having, a specified breakdown characteristic (not power types), S transistor for switching applications (not power types), T controlling and switching power device (e.g. thyristor), having a specified breakdown characteristic., U power transistor for switching applications, X multiplier diode such as varactor or step recovery diode, Y rectifier diode, booster diode, efficiency diode, Z voltage reference or voltage regulator diode, transient, suppressor diode., , The second (and third) letter(s) indicate the general class, of the device., 12, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.161, , Copyright @ NIMI Not to be Republished

Page 27 :

The remainder of the type number is a serial number, indicating a particular design or development, and is in one, of the following two groups., , The colour coding of capacitors and resistors are same., Where as, in the case of fixed capacitors, the colour coded, unit shall be in Picofarads., , a Devices intended primarily for use in consumer, applications (radio and television receivers, audioamplifiers, tape recorders, domestic appliances, etc.), The serial number consists of three figures., , For letter coding, incase of capacitor, the letter ‘p’, ‘n’, ‘μ’, shall be used as multipliers. Where p = 10-12, n= 10-9 and, μ = 10-6 farads, and letter code for tolerance on capacitor, is the same as in resistor., , b Devices intended mainly for applications other than (a), e.g. industrial, professional and transmitting, equipments., The serial number consists of one letter (Z,Y,X,W etc), followed by two numbers (digits), The International System follows letters 1N, 2N, 3N etc, followed by four numbers., 1N, , indicates single junction, , 2N, , indicates two junction, , 3N, , indicates three junctions., , Inductor: The ability of the conductor to induce voltage in, itself, when the current changes in it is called as self, inductance (or) simply inductance. A coil introduced in a, circuit to have inductance is called as inductor. Different, type of inductors are shown in Fig 8. The unit of inductance, is “Henry”. Commercially a coil may have inductance in, Millihenry (10-3H), or in Microhenry (10-6H)., , The number indicates internationally agreed manufacturer’s, code e.g. 1N 4007, 2N 3055, 3N 2000., Again, manufacturers use their own codes for, semiconductor devices. Manufacturers in Japan use 2SA,, 2SB, 2SC, 2SD etc. followed by a group of numbers e.g., 2SC 1061, 2SA 934, 2SB 77. Indian manufacturers have, their own codes too., Passive and active electronic components, Introduction: The Components used in electronic circuits, can broadly grouped under two headings., , While specifying the inductance the following factors to be, considered, , – passive components, , •, , nominal value of inductance in Henry / Millihenry /, Microhenry., , •, , tolerance in percentage (±5/10/20%), , •, , type of winding like single layer, double layer, multilayer, and pie (p) etc., , •, , type of core like air core, iron core, ferrite core, , •, , type of application like audio frequency (AF), Radio, frequency (RF) coupling coil, filter coil etc.,, , – active components, Passive components: Components like resistors,, capacitors, and inductors used in electronic circuit are, called as passive components. These components by, themselves are not capable of amplifying or processing an, electrical signal. However these components are equally, important in electronic circuit as that of active components,, without the aid of passive components, a transistor (active, components) cannot be made to amplify electrical signal., Circuits formed with passive components obey the electrical, circuits laws such as ohm’s law, Kirchoff’s Laws etc.,, Resistors: The components whose purpose to introduce, resistance in the circuit is called as resistors. Other, details of resistors are dealt in earlier lessons., Capacitor: The components whose purpose to introduce, capacitance in the circuit is called as capacitor. The unit, of capacitance is ‘FARAD’. Commercially capacitors are, available in Microfarad (μF), Nanofarad (nF) and, Picofarads (pF)., , In an electronic circuit some time, it is also required to vary, the inductance., The inductance of a coil can be varied by:•, , providing tapped inductive coil, as in Fig 9 or, , •, , adjusting the core of a coil as in Fig 10., , However, all inductor coils have inherent resistance due to, the resistance of the winding wire in the coil. Further the, maximum current that can be safely carried by an inductor, depends upon the size of the winding wire used., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.161, , Copyright @ NIMI Not to be Republished, , 13

Page 28 :

SCR (Silicon controlled rectifier) : Figure 14a shows, the physical appearance of one type of SCR and the, symbol is shown in Fig 14b. SCRs are also called, thyristors and used as switching devices., , Active components, In electronic circuit, the components, other than passive, are known as active components. Namely, transistors,, diodes, SCRs Vacuum tubes etc.,, Active components : In electronic circuits, components, other than resistors, capacitors and inductors are also, used. Namely, transistors, diodes, vacuum tubes, SCRs,, diacs, zener-diode (Fig 11) etc. The application of electrical, circuit laws (Ohm’s law etc.) in the circuit containing the, above components will not give correct results. i.e. these, components do not obey. Ohm’s law, Kirchoff’s law etc., These components are called active components., , Diac : A diac (Fig 15a) is a two-lead device like a diode., It is a bidirectional switching device. Its symbol is shown, in Fig 15b., , The different active components and the method of, representing them by symbols in the circuit diagram are, given below (Fig 11), , Triac : A triac is also a semiconductor device with three, leads like two SCRs in parallel. The triac can control the, circuit in either direction. (Fig 16), , The different types of diodes (Fig 12) used for specific, purposes are represented by the symbols given., Transistor : Figure 13a shows the physical appearance of, transistors. There are two symbols to represent a transistor., (Fig 13b). The selection of a symbol is based on either the, NPN or the PNP type of transistor., 14, , Bridge rectifier or diode bridge : It is a single package, of four semiconductor diodes connected in bridge circuit., The input AC and the output DC leads are marked and, terminated as shown in the Figure 17., UJT (Uni-junction transistor) : It has two doped regions, with three leads and has one emitter and two bases, (Fig 18)., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.161, , Copyright @ NIMI Not to be Republished

Page 29 :

FET (Field effect transistor) : Fig 19a give a pictorial view, of the component, and the related symbol to represent the, field effect transistor is shown in Fig 19b. The selection of, the symbol is based on whether the FET is a ‘N’ channel, or a ‘P’ channel one., , In the active components few basic components discussed, have and many more advanced components associated, with modern circuits are in use., , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.161, , Copyright @ NIMI Not to be Republished, , 15

Page 30 :

Electrical, Electrician - Electronic Practice, , Related Theory for Exercise 4.1.162, , PN Junction - semi conductor diodes, Objectives: At the end of this lesson you shall be able to, • explain diffusion in PN junction and barrier potential, • explain forward and reverse biasing of PN junction and semi conductor diodes and its VI characteristics, • state the applications specifications and classification of diodes, • state the different industry standards for diode numbering and finding equivalents of diode, • state the method of testing diode and identifying the polarity, • state special diodes and their functions and PIV., PN junction: A diode is made by combining P and N, materials. The surface at which these materials meet is, the PN junction., Diffusion occurs when P and N materials are joined, together.(Fig 1) some electrons in the N material, near the, junction, are attracted to the holes in the P material, thus, leaving holes in the N material. The diffusion of electrical, charges produces a potential difference in a small area, near the junction (Fig 2).As a result, the material will, conduct in one direction but not in the opposite direction., For this reason, the area in which this emf exists is called, a barrier., , The internal barrier potential (Vb) : Although it is an, internal contact potential that cannot be measured directly,, the effect can be overcome by 0.3V for a Ge junction or 0.7, V for Si. The barrier voltage is more for Si because its lower, atomic number allows more stability in the covalent bonds, as already stated., The PN junction, with the depletion zone magnified, shows, the iron that has +ve and -ve charges produce the internal, contact potential Vb at the barrier. (Fig 2), A PN device is knows as a diode. The diode and its symbol, are in Fig 3. This type of construction permits the current, to flow in one direction but not in the opposite direction., Biasing the PN junction, Forward Bias : A forward-biased PN junction is in Fig 4, The positive terminal is connected to the P-side and the, negative terminal of the DC supply is connected to the, N-side of the junction., , 16, , A current will flow through the diode as in the, Fig 4. The positive terminal for the battery attracts, electrons from P material, leaving an excess of holes., Because electrons are drifting away from the junction, the, excess holes tend to accumulate near the junction. At the, same instant, electrons from the negative terminal of the, battery are attracted to the less negative N material of the, diode. This action overcomes the barrier at the junction, and allows the electrons to move into the excess holes of, the P material, the result is a continuous flow of electrons, in one direction. The voltage required to move the charge, carries in forward bias conduction called the barrier, voltage., Reverse Bias: If the polarities of the DC supply are as, shown in Fig 5, the PN junction is said to be reversebiased. That is, the P side is connected to the negative, and the N-side is connected to the positive terminals of the, supply. Fig 5 shows the battery connection reversed, (reverse bias). At the same instant, a shift in electrons in, the P material causes the positive holes to appear further, , Copyright @ NIMI Not to be Republished

Page 31 :

away from the junction near the end for the diode, which, is connected to the negative terminal of the battery. This, action produces a wider barrier at the PN junction through, which the electrons cannot flow. (A very small current, leakage may however occur)., , The current in the forward direction increases rapidly upon, reaching the forward voltage Vb which is known as the, barrier potential or the junction potential and the barrier, potential for germanium is 0.3 V and for silicon it is 0.7 V., The behaviour of the PN junction is limited by the maximum, forward current, as too much of current may destroy a, diode due to the excess heat generation., The current in the reverse direction of the junction is very, small. Upon reaching —Vb in the reverse direction, the, reverse current suddenly increases. —Vb in the reverse, direction where the current starts increasing is called the, knee potential or breakdown voltage. Normally the diode, should not be operated in this region. The knee voltage, depends on the type of diode which varies from 3V to 20, kV or more., Application of diodes : Semi conductor diodes are used, for various applications. Some of the major areas of, application are listed below., •, , Modulation and demodulation in communication, receivers., , •, , Switching high speed digital circuits, , •, , Low power and high power rectification, , •, , As surge protectors in EM relay and other circuits., , •, , For clipping, clamping wave-forms., , For different applications, diodes of different current carrying, capacity, different PIV capacity and so on are required., Therefore, manufacturers make diodes to cater to varied, applications with different specifications. Before using a, diode for a particular application, it is a must to find out, whether the voltage, current, and temperature, characteristics of the given diode match the requirement, or not., Important specifications of a diodes, V-I characteristic of PN junction : The static current, voltage characteristic is in Fig 6., , The material : The diode is made-of dopped semiconductor material. This could be Silicon or Germanium, or Selenium.This is important because the cut-in voltage, depends upon the material the diode is made-of. For, example, in Ge diodes the cut-in voltage is around 0.3V,, whereas in Si diodes the cut-in voltage is around 0.7V., Maximum safe reverse voltage : Denoted as VR or Vr, that can be applied across the diode. This is known as, peak-inverse-voltage or PIV. If a higher reverse voltage, than the rated PIV is applied across the diode, it will, become defective permanently., Maximum average forward current : If or IF that a diode, can allow to flow through it without getting damaged., Forward voltage drop : VF or Vf that appears across the, diode when the maximum average current, If flows through, it continuously, , Electrical : Electrician (NSQF LEVEL - 5) - Related Theory for Exercise 4.1.162, , Copyright @ NIMI Not to be Republished, , 17

Page 32 :